QIBR guide rails are delivered to customers in Cologne, Germany, for use in automated assembly lines to ensure stability and high efficiency

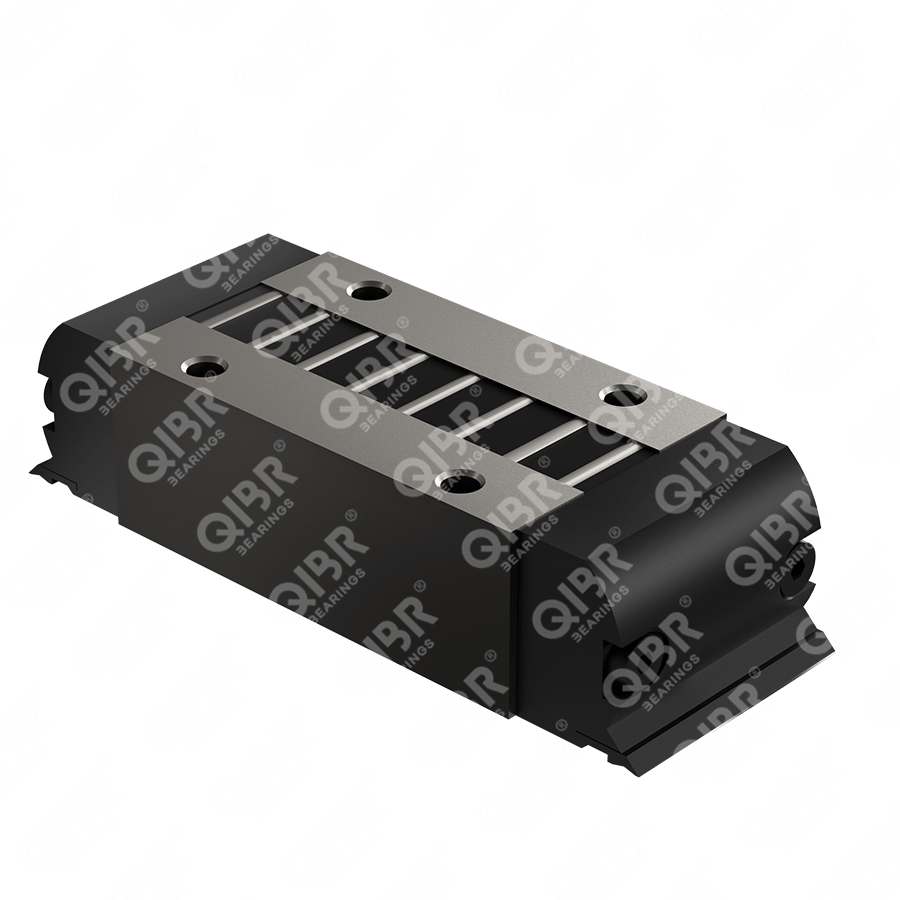

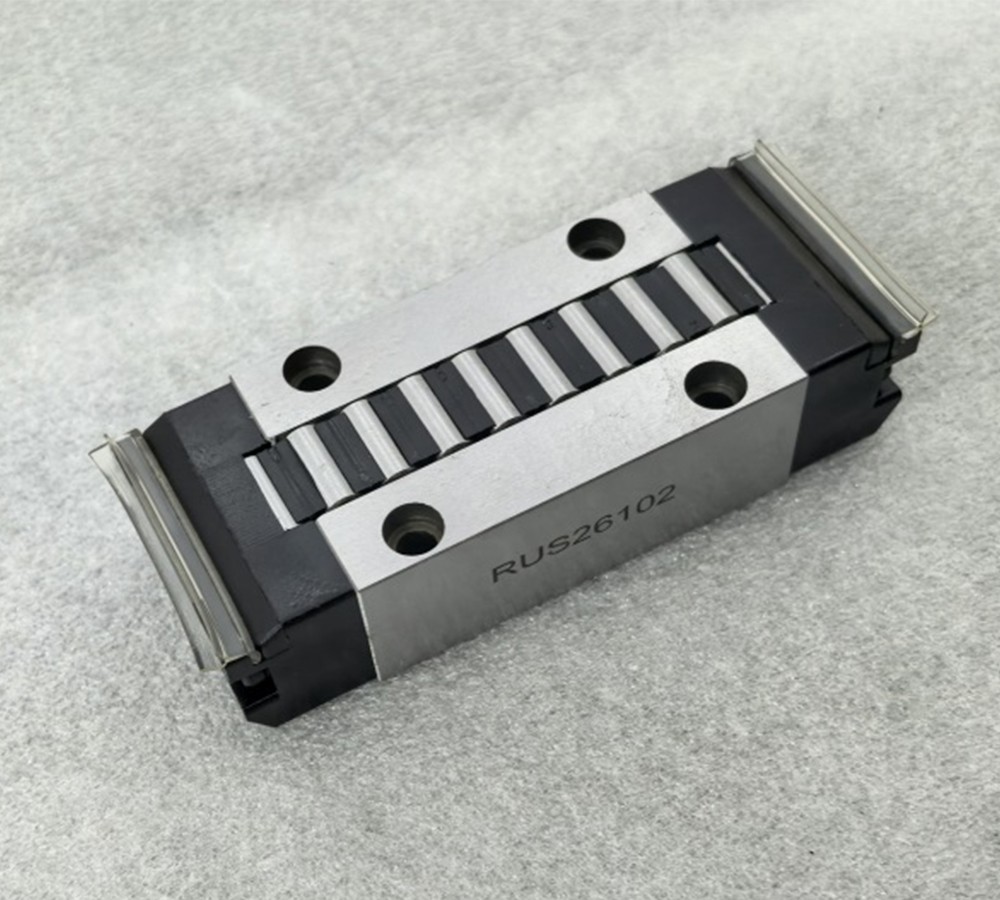

Rails

1. Precise Positioning: The RUS26102 guide rail can make the moving parts move along the predetermined linear trajectory, ensure the directionality of movement, and reduce positioning errors caused by offset or misalignment. Combined with the precise design of the slider, ultra-high positioning accuracy is achieved. High precision helps improve the accuracy of the assembly process and reduce assembly errors.

2. High Rigidity: The RUS26102 guide rail can ensure that the moving parts move smoothly along the predetermined path and ensure high-precision positioning and repeated positioning. The slider can move smoothly at high speed, greatly improving assembly efficiency, reducing rework and material waste caused by errors, and improving production efficiency.

3. Low Friction and High Efficiency: The balls of QIBR RUS26102 guide rails are made of high-strength and wear-resistant materials, with good surface smoothness and wear resistance, which can effectively reduce friction. When the moving parts move on the guide rail, the required driving force is greatly reduced, improving energy efficiency.

Additional Notes:

German customers have decided to purchase RUS26102 guide rails from QIBR company to meet the needs of their automated assembly lines for stability and high efficiency. The RUS26102 guide rail adopts high-strength and wear-resistant materials, provides high-precision, high-efficiency, and low-friction linear motion, and plays a key role in automated assembly lines to ensure reliability under high loads and high-speed operation conditions. The high-performance RUS26102 guide rail can improve the working efficiency of automated assembly lines and make the production process more smooth.