The slewing bearings of QIBR were delivered to the customer in Rome, Italy, to improve the safety and smoothness of the window cleaning machine

- Continent

- Europe

- Country

- Italy

- Date

- 2016-07-14

- Categories

-

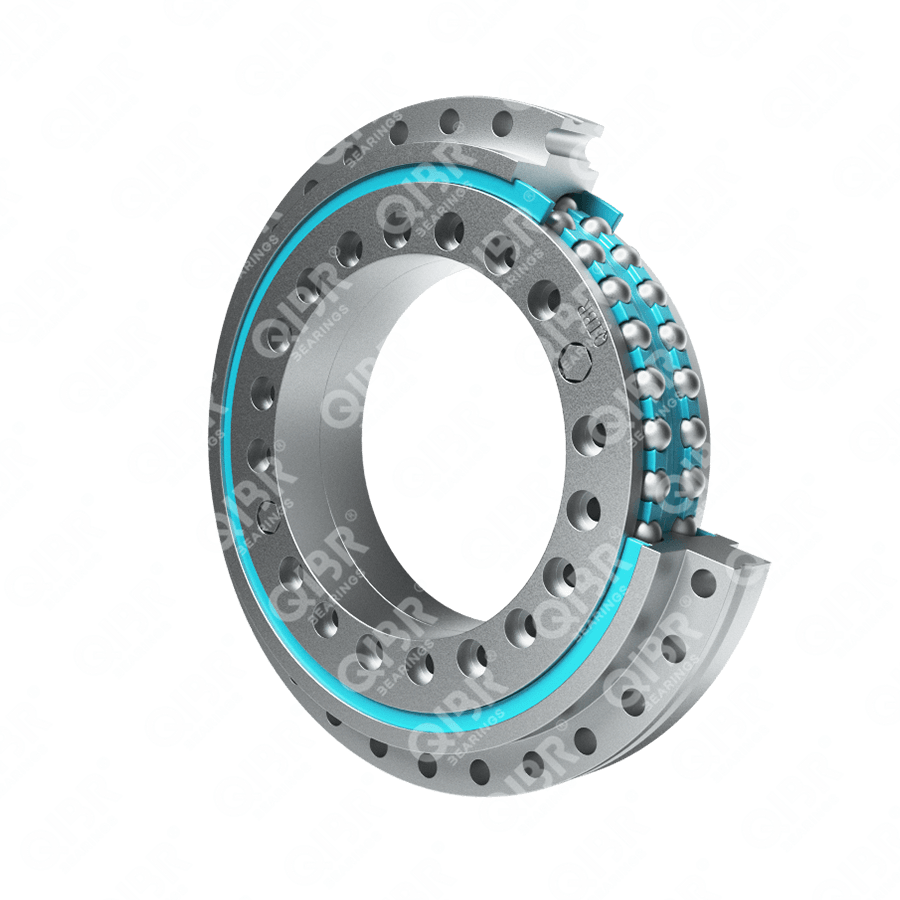

Slewing Bearing

- Applications

- Window Cleaning Machine

Products Used

Slewing bearing

1. Strong Load Capacity: The ZKLDF200 slewing bearings can withstand various loads such as axial, radial and overturning moments simultaneously. It is suitable for the gravity and operating forces that the window cleaning machine faces during use. It ensures the stability and safety of the window cleaning machine during operation.

2. Smooth Rotation Performance: The ZKLDF200 slewing bearings provide smooth rotation, support multi-directional rotation and tilting movements, reduce vibrations and noises, and meet the flexibility required by the window cleaning machine during the cleaning process. It ensures that the window cleaning machine can operate continuously, guarantees the smoothness of the operation process, and enhances the user experience.

3. Friction Reduction: The high-quality ZKLDF200 slewing bearings are made of wear-resistant materials and can resist wear during long-term use, extending the service life of the product. It reduces the need for frequent replacement of parts and lowers the maintenance cost.

Additional Notes:

After evaluating various ZKLDF200 slewing bearings on the market, the Italian customer finally chose the ZKLDF200 slewing bearing products of QIBR Company, aiming to improve the safety and smoothness of the window cleaning machine. The ZKLDF200 slewing bearings are made of high-strength steel and advanced production processes to ensure durability under high loads and extreme environments. It guarantees good rotation accuracy and smooth movement. The window cleaning machine can move more smoothly during work, reducing vibrations and noises, and enhancing the comfort of operation. The smoothness of the ZKLDF200 slewing bearings not only improves the work efficiency but also reduces the fatigue of the operators and enhances the safety of the overall operation.