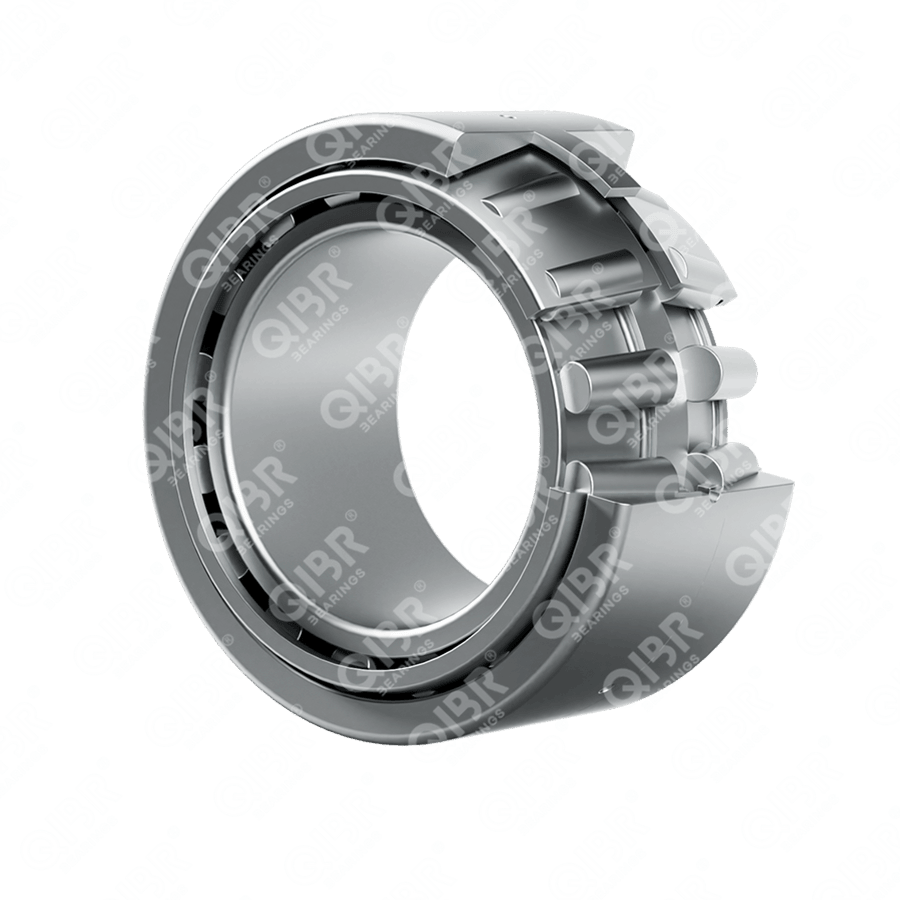

Image may differ from product. See technical specification for details.

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh,DIN / VDEh

Material

Bearing steel, Stainless steel, Carburized steel

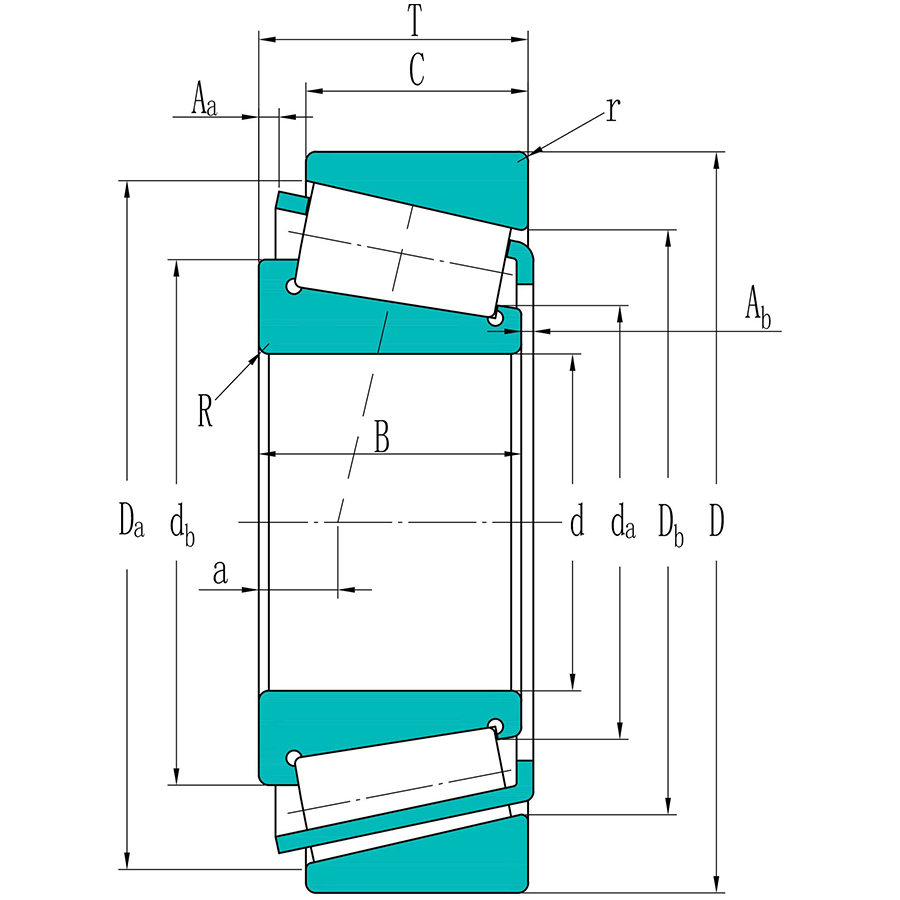

Inner diameter (d)

15-60 mm

Cup outer diameter (D)

42-140 mm

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Automotive industry; Mechanical equipment; Precision instruments; Aerospace; Railway transportation; Electric Energy etc

| NO. | Product | Product Number | Basic dynamic load rating | Basic static load rating | Bore | Outer diameter (D) | Overall width (T) | Mass |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

T7FC045T62/DTC10 | 189 KN | 224 KN | 45 mm | 95 mm | 62 mm | 2.05 kg |

| 2 |

|

T7FC050T69/DTC10 | 229 KN | 275 KN | 50 mm | 105 mm | 69 mm | 2.75 kg |

| 3 |

|

T7FC055T73/DTC10 | 266 KN | 325 KN | 55 mm | 115 mm | 73 mm | 3.5 kg |

| 4 |

|

T7FC060T80/DTC15 | 325 KN | 405 KN | 60 mm | 125 mm | 80 mm | 4.55 kg |

| 5 |

|

T7FC065T80/DTC15 | 332 KN | 430 KN | 65 mm | 130 mm | 80 mm | 4.8 kg |

| 6 |

|

T7FC080T98/DTC20 | 480 KN | 630 KN | 80 mm | 160 mm | 98 mm | 8.8 kg |

| 7 |

|

32211/DF | 222 KN | 260 KN | 55 mm | 100 mm | 53.5 mm | 1.75 kg |

| 8 |

|

31311/DF | 256 KN | 275 KN | 55 mm | 120 mm | 63 mm | 3.25 kg |

| 9 |

|

30311/DF | 302 KN | 325 KN | 55 mm | 120 mm | 63 mm | 3.25 kg |

| 10 |

|

32012X/DF | 173 KN | 245 KN | 60 mm | 95 mm | 46 mm | 1.2 kg |

| 11 |

|

30212/DF | 207 KN | 228 KN | 60 mm | 110 mm | 47.5 mm | 1.8 kg |

| 12 |

|

32212/DF | 266 KN | 320 KN | 60 mm | 110 mm | 59.5 mm | 2.4 kg |

| 13 |

|

32206/DF | 106 KN | 116 KN | 30 mm | 62 mm | 42.5 mm | 0.59 kg |

| 14 |

|

30206/DF | 85.7 KN | 88 KN | 30 mm | 62 mm | 34.5 mm | 0.48 kg |

| 15 |

|

31306/DF | 100 KN | 100 KN | 30 mm | 72 mm | 41.5 mm | 0.82 kg |

| 16 |

|

30306/DF | 119 KN | 112 KN | 30 mm | 72 mm | 41.5 mm | 0.81 kg |

| 17 |

|

32007X/DF | 89.7 KN | 108 KN | 35 mm | 62 mm | 36 mm | 0.46 kg |

| 18 |

|

32207/DF | 139 KN | 156 KN | 35 mm | 72 mm | 48.5 mm | 0.91 kg |

| 19 |

|

33207/DF | 178 KN | 212 KN | 35 mm | 72 mm | 56 mm | 1.1 kg |

| 20 |

|

31307/DF | 129 KN | 134 KN | 35 mm | 80 mm | 45.5 mm | 1.1 kg |

| 21 |

|

30307/DF | 152 KN | 150 KN | 35 mm | 80 mm | 45.5 mm | 1.05 kg |

| 22 |

|

33108/DF | 167 KN | 208 KN | 40 mm | 75 mm | 52 mm | 1.05 kg |

| 23 |

|

30208/DF | 130 KN | 137 KN | 40 mm | 80 mm | 39.5 mm | 0.87 kg |

| 24 |

|

31308/DF | 156 KN | 163 KN | 40 mm | 90 mm | 50.5 mm | 1.5 kg |

| 25 |

|

32009X/DF | 123 KN | 160 KN | 45 mm | 75 mm | 40 mm | 0.71 kg |

| 26 |

|

33015/DFC240 | 286 KN | 455 KN | 75 mm | 115 mm | 62 mm | 2.4 kg |

| 27 |

|

33115/DF | 370 KN | 530 KN | 75 mm | 125 mm | 74 mm | 3.65 kg |

| 28 |

|

30215/DF | 293 KN | 355 KN | 75 mm | 130 mm | 54.5 mm | 2.85 kg |

| 29 |

|

32215/DF | 337 KN | 425 KN | 75 mm | 130 mm | 66.5 mm | 3.4 kg |

| 30 |

|

33215/DF | 436 KN | 600 KN | 75 mm | 130 mm | 82 mm | 4.5 kg |

| 31 |

|

31315/DF | 438 KN | 490 KN | 75 mm | 160 mm | 80 mm | 7.15 kg |

| 32 |

|

32209/DF | 169 KN | 196 KN | 45 mm | 85 mm | 49.5 mm | 1.2 kg |

| 33 |

|

31309/DF | 194 KN | 204 KN | 45 mm | 100 mm | 54.5 mm | 2 kg |

| 34 |

|

30309/DF | 227 KN | 240 KN | 45 mm | 100 mm | 54.5 mm | 2 kg |

| 35 |

|

32010X/DF | 129 KN | 176 KN | 50 mm | 80 mm | 40 mm | 0.78 kg |

| 36 |

|

33010/DF | 145 KN | 204 KN | 50 mm | 80 mm | 48 mm | 0.92 kg |

| 37 |

|

32213/DF | 320 KN | 390 KN | 65 mm | 120 mm | 65.5 mm | 3.1 kg |

| 38 |

|

31313/DF | 348 KN | 380 KN | 65 mm | 140 mm | 72 mm | 5 kg |

| 39 |

|

32014X/DF | 214 KN | 305 KN | 70 mm | 110 mm | 50 mm | 1.75 kg |

| 40 |

|

33014/DF | 273 KN | 400 KN | 70 mm | 110 mm | 62 mm | 2.2 kg |

| 41 |

|

33114/DF | 361 KN | 500 KN | 70 mm | 120 mm | 74 mm | 3.45 kg |

| 42 |

|

32214/DF | 334 KN | 415 KN | 70 mm | 125 mm | 66.5 mm | 3.3 kg |

| 43 |

|

31314/DF | 393 KN | 440 KN | 70 mm | 150 mm | 76 mm | 6.1 kg |

| 44 |

|

33015/DF | 286 KN | 455 KN | 75 mm | 115 mm | 62 mm | 2.4 kg |

| 45 |

|

30210/DF | 160 KN | 183 KN | 50 mm | 90 mm | 43.5 mm | 1.1 kg |

| 46 |

|

32210/DF | 173 KN | 200 KN | 50 mm | 90 mm | 49.5 mm | 1.3 kg |

| 47 |

|

33210/DF | 243 KN | 320 KN | 50 mm | 90 mm | 64 mm | 1.75 kg |

| 48 |

|

31310/DF | 224 KN | 240 KN | 50 mm | 110 mm | 58.5 mm | 2.55 kg |

| 49 |

|

32011X/DF | 170 KN | 232 KN | 55 mm | 90 mm | 46 mm | 1.15 kg |

| 50 |

|

33011/DF | 191 KN | 270 KN | 55 mm | 90 mm | 54 mm | 1.35 kg |

| 51 |

|

30211/DF | 190 KN | 212 KN | 55 mm | 100 mm | 45.5 mm | 1.45 kg |

| 52 |

|

33212/DF | 354 KN | 475 KN | 60 mm | 110 mm | 76 mm | 3.15 kg |

| 53 |

|

31312/DF | 303 KN | 335 KN | 60 mm | 130 mm | 67 mm | 4.05 kg |

| 54 |

|

30312/DF | 357 KN | 390 KN | 60 mm | 130 mm | 67 mm | 4.1 kg |

| 55 |

|

32312/DF | 483 KN | 585 KN | 60 mm | 130 mm | 97 mm | 6.05 kg |

| 56 |

|

32013X/DF | 176 KN | 255 KN | 65 mm | 100 mm | 46 mm | 1.3 kg |

| 57 |

|

33013/DF | 204 KN | 310 KN | 65 mm | 100 mm | 54 mm | 1.55 kg |

| 58 |

|

30213/DF | 242 KN | 270 KN | 65 mm | 120 mm | 49.5 mm | 2.3 kg |

| 59 |

|

32315/DF | 713 KN | 880 KN | 75 mm | 160 mm | 116 mm | 11 kg |

| 60 |

|

32016X/DF | 288 KN | 430 KN | 80 mm | 125 mm | 58 mm | 2.65 kg |

| 61 |

|

30217/DF | 370 KN | 440 KN | 85 mm | 150 mm | 61 mm | 4.25 kg |

| 62 |

|

32217/DF | 451 KN | 570 KN | 85 mm | 150 mm | 77 mm | 5.4 kg |

| 63 |

|

33217/DF | 606 KN | 850 KN | 85 mm | 150 mm | 98 mm | 7.3 kg |

| 64 |

|

31317/DF | 510 KN | 570 KN | 85 mm | 180 mm | 89 mm | 9.9 kg |

| 65 |

|

32018X/DF | 356 KN | 540 KN | 90 mm | 140 mm | 64 mm | 3.65 kg |

| 66 |

|

33018/DF | 457 KN | 710 KN | 90 mm | 140 mm | 78 mm | 4.5 kg |

| 67 |

|

30218/DF | 411 KN | 490 KN | 90 mm | 160 mm | 65 mm | 5.2 kg |

| 68 |

|

33116/DF | 379 KN | 560 KN | 80 mm | 130 mm | 74 mm | 3.8 kg |

| 69 |

|

32216/DF | 391 KN | 490 KN | 80 mm | 140 mm | 70.5 mm | 4.25 kg |

| 70 |

|

33216/DF | 527 KN | 750 KN | 80 mm | 140 mm | 92 mm | 5.95 kg |

| 71 |

|

31316/DF | 473 KN | 530 KN | 80 mm | 170 mm | 85 mm | 8.65 kg |

| 72 |

|

32316/DF | 693 KN | 1000 KN | 80 mm | 170 mm | 123 mm | 13 kg |

| 73 |

|

32017X/DF | 293 KN | 450 KN | 85 mm | 130 mm | 58 mm | 2.8 kg |

| 74 |

|

33017/DF | 382 KN | 620 KN | 85 mm | 130 mm | 72 mm | 3.5 kg |

| 75 |

|

32019X/DF | 353 KN | 540 KN | 95 mm | 145 mm | 64 mm | 3.8 kg |

| 76 |

|

33019/DF | 467 KN | 735 KN | 95 mm | 145 mm | 78 mm | 4.7 kg |

| 77 |

|

32219/DF | 597 KN | 780 KN | 95 mm | 170 mm | 91 mm | 8.4 kg |

| 78 |

|

31319/DF | 539 KN | 710 KN | 95 mm | 200 mm | 99 mm | 13.5 kg |

| 79 |

|

32920/DF | 252 KN | 405 KN | 100 mm | 140 mm | 50 mm | 2.35 kg |

| 80 |

|

32020X/DF | 359 KN | 560 KN | 100 mm | 150 mm | 64 mm | 3.9 kg |

| 81 |

|

30220/DF | 521 KN | 640 KN | 100 mm | 180 mm | 74 mm | 7.5 kg |

| 82 |

|

32218/DF | 529 KN | 680 KN | 90 mm | 160 mm | 85 mm | 6.85 kg |

| 83 |

|

31318/DF | 486 KN | 630 KN | 90 mm | 190 mm | 93 mm | 11.5 kg |

| 84 |

|

32318/DF | 835 KN | 1220 KN | 90 mm | 190 mm | 135 mm | 17.5 kg |

| 85 |

|

32220/DF | 668 KN | 880 KN | 100 mm | 180 mm | 98 mm | 10 kg |

| 86 |

|

30320/DF | 739 KN | 980 KN | 100 mm | 215 mm | 103 mm | 17 kg |

| 87 |

|

31320X/DF | 685 KN | 930 KN | 100 mm | 215 mm | 113 mm | 18.5 kg |

| 88 |

|

32320/DF | 1057 KN | 1560 KN | 100 mm | 215 mm | 155 mm | 26 kg |

| 89 |

|

32021X/DF | 426 KN | 670 KN | 105 mm | 160 mm | 70 mm | 5.05 kg |

| 90 |

|

30221/DF | 571 KN | 710 KN | 105 mm | 190 mm | 78 mm | 9 kg |

| 91 |

|

32221/DF | 760 KN | 1020 KN | 105 mm | 190 mm | 106 mm | 12.5 kg |

| 92 |

|

32022X/DF | 494 KN | 780 KN | 110 mm | 170 mm | 76 mm | 6.3 kg |

| 93 |

|

32022X/DFC200 | 494 KN | 780 KN | 110 mm | 170 mm | 76 mm | 6.3 kg |

| 94 |

|

33122/DF | 781 KN | 1250 KN | 110 mm | 180 mm | 112 mm | 11.5 kg |

| 95 |

|

30222/DF | 561 KN | 800 KN | 110 mm | 200 mm | 82 mm | 10.5 kg |

| 96 |

|

32222/DF | 842 KN | 1140 KN | 110 mm | 200 mm | 112 mm | 14.5 kg |

| 97 |

|

31322X/DF | 841 KN | 1160 KN | 110 mm | 240 mm | 126 mm | 26 kg |

| 98 |

|

32322/DF | 1158 KN | 1660 KN | 110 mm | 240 mm | 169 mm | 35 kg |

| 99 |

|

30326/DF | 1165 KN | 1600 KN | 130 mm | 280 mm | 127.5 mm | 35 kg |

| 100 |

|

31326X/DF | 1110 KN | 1560 KN | 130 mm | 280 mm | 144 mm | 39.5 kg |

Single-row metric tapered roller bearings solve several key problems in various fields, which are mainly reflected in the following aspects:

1. Single-row metric tapered roller bearings have high load-bearing capacity

The contact angle between the inner ring, outer ring and roller of a single-row metric tapered roller bearing is usually a cone, which can bear large radial and axial loads at the same time. Due to its rolling contact method, the load distribution of this type of bearing is relatively uniform and the load-bearing capacity is relatively high.

2. Single-row metric tapered roller bearings have good wear resistance

Single-row metric tapered roller bearings are particularly suitable for bearing radial loads and axial loads acting simultaneously. The contact angle of the bearing (usually between 15° and 30°) determines its load-bearing capacity for axial loads, so it is often selected in applications with high loads and high reliability requirements.

3. Single-row metric tapered roller bearings have adjustable clearance

During the installation process of single-row metric tapered roller bearings, the radial clearance between the inner and outer rings can be adjusted according to actual needs. This adjustability enables the bearings to adapt to different working conditions and thus obtain the best operating performance.

4. Good adaptability

Due to the geometric characteristics between the inner and outer rings and rolling elements of the single-row metric tapered roller bearings, it can adapt to a certain axial displacement. During the process of operation, the bearings can effectively withstand the eccentricity or axial displacement of the shaft and have good adaptability.

Performance improvement and solutions for single-row metric tapered roller bearings

1. Improve high-speed adaptability

Improve the structure of the bearing, reduce the friction between the inner and outer rings, and reduce the temperature rise during the process of operation, thereby improving the high-speed operation capability of the bearing.

2. Corrosion resistance

By selecting corrosion-resistant materials, or surface coatings or plating, the working ability of the bearing in harsh environments such as moisture, salt spray, acid and alkali can be improved, and the service life can be extended.

3. Improve manufacturing accuracy

Adopt advanced foreign processing equipment and processes, such as precision grinding, super-finishing grinding, etc., to improve the geometric accuracy of the inner and outer rings and rollers, reduce processing errors, and thus improve the rotation accuracy and roughness of the bearing.

4. Improve material properties

The carburizing process is used to harden the surface of the material, while its core (heart) still retains a low hardness and good toughness. This structure enables the bearing to maintain sufficient toughness when subjected to large loads, avoiding cracking or fragmentation due to impact or excessive fatigue.

Main application areas of single-row metric tapered roller bearings

1. Differentials

Single-row metric tapered roller bearings used in differentials can support the torque and pressure of vehicles when turning.

2. Axles

Single-row metric tapered roller bearings used in railway axles can effectively support the radial and axial loads of axles and provide smooth running performance in long-term use.

3. Marine engines

Single-row metric tapered roller bearings used in marine engines can withstand large axial and radial loads.

4. Tractors and agricultural equipment

In agricultural machinery, single-row metric tapered roller bearings are used in parts that withstand high axial and radial loads.