QIBR joint bearings and tapered roller bearings were delivered to our customer in Leeds, UK, to improve the stability and load-bearing capacity of the steering system of the excavator.

- Continent

- Europe

- Country

- United Kingdom

- Date

- 2016-03-17

- Categories

-

Joint Bearing

Tapered Roller Bearing

- Applications

- excavator steering system

Products Used

Tapered roller bearings

1. Self-aligning ability : The tapered design of the inner and outer ring raceways has a large contact area, which can disperse the radial and axial loads applied to the bearings and improve the load-bearing capacity. It is suitable for use as a key component in the steering system of excavators.

2. High load-carrying capacity : The 32221 tapered roller bearings are made of high-strength, wear-resistant materials to ensure reliability under high loads and harsh environments. After precision machining and heat treatment, they can effectively resist wear and fatigue, improve overall performance, provide high-precision motion control, and ensure the stability of the excavator when steering.

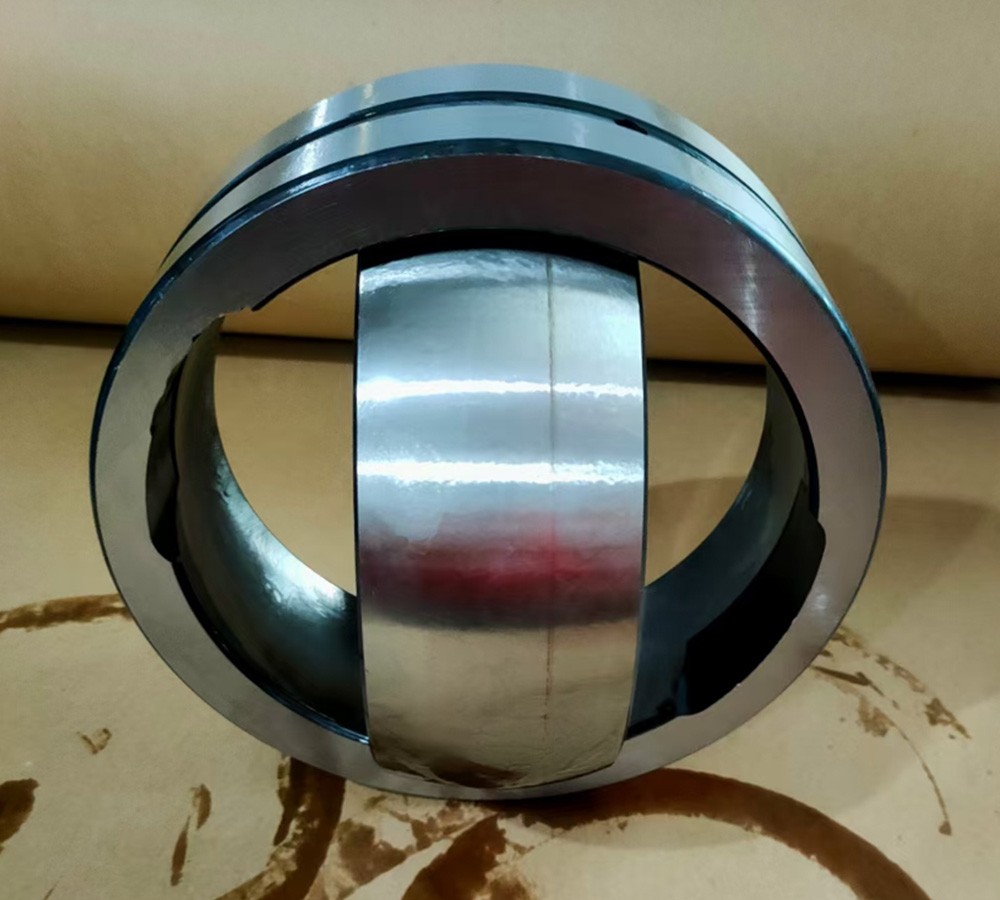

Joint Bearing

1. Low friction and high wear resistance : GE140DO joint bearing has a large contact area, which can effectively disperse the load applied to the bearing, improve its load-bearing capacity, and adapt to the high-load working conditions of the excavator steering system.

2. Strong load-carrying capacity : The friction coefficient of the GE140DO joint bearing is relatively low, which helps to reduce energy loss and improve overall operating efficiency.

Additional Notes:

The British customer decided to purchase GE140DO joint bearings and 32221 tapered roller bearings from QIBR to meet the strict requirements of its excavator steering system in terms of stability and high load-bearing capacity. QIBR GE140DO joint bearings have a low friction coefficient, which can effectively improve the overall operating efficiency of the excavator. The 32221 tapered roller bearings are designed to withstand large radial and axial loads at the same time. The use of the two bearings in combination can enable the excavator to complete tasks faster during operation, improve operating efficiency, and reduce energy consumption. QIBR not only provides high-quality products, but also provides customers with comprehensive technical support and after-sales service, which will create greater value for customers.