Newsroom

Disassembly of ball bearings

2025-04-03The disassembly of ball bearings should be carried out according to the specific application scenario and installation method to avoid damage to the bearing or related components. Below are the general disassembly steps and precautions:

1.Preparatory Work

I.Ensure Safety: Make sure the equipment is powered off, stopped, and necessary safety measures are taken.

II.Clean the Surface: Remove dust and dirt around the ball bearing to prevent foreign objects from entering the bearing.

III.Check the Structure: Understand the bearing’s installation method (such as tight fit, interference fit, or snap ring fixation) and choose an appropriate disassembly method.

2.Disassembly Methods

I.Manual Disassembly (Suitable for Small Ball Bearings)

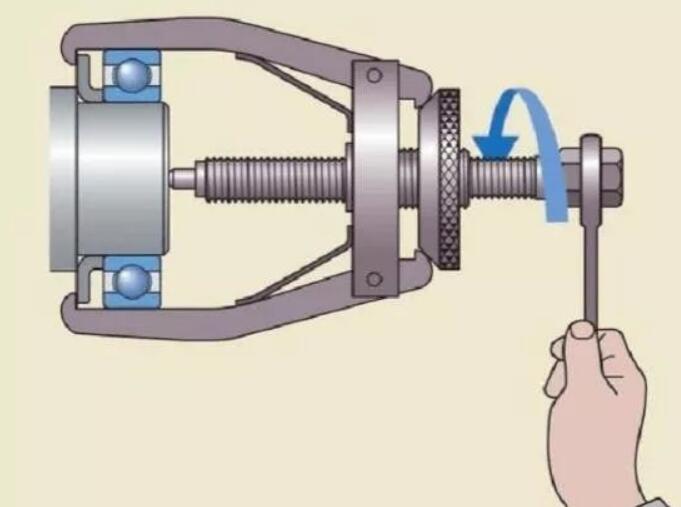

Using a Puller: Use a two-jaw or three-jaw puller to apply even force and pull the bearing out.

Press-out Method: Apply mechanical pressure to push the bearing out from the shaft, ensuring even force distribution.

II.Heating Disassembly (Suitable for Interference Fit Bearings)

Induction Heating Method: Use an induction heater or hot air gun to heat the bearing, allowing it to expand for easier removal.

Oil Bath Heating Method: Heat the bearing to 80-100°C, causing it to expand, and then remove it quickly.

III.Hydraulic Disassembly (Suitable for Large Ball Bearings)

Hydraulic Nut: Used for bearings installed on tapered shafts, hydraulic nuts can be used to push the bearing off.

Oil Pressure Method: Inject high-pressure oil into the oil groove between the bearing and shaft, creating an oil film that loosens and slides the bearing out.

3.Precautions

I.Avoid Hammering: Do not directly strike the bearing with a hammer to prevent damage to the raceway or rolling elements.

II.Apply Even Force: Use appropriate tools to ensure even force distribution, preventing damage to the bearing or shaft.

III.Maintain Cleanliness: After disassembly, clean the bearing and installation area immediately to avoid contamination by dust or debris.

If the ball bearing needs to be reused, it is recommended to use more gentle disassembly methods to maintain its precision and performance.

For more information, feel free to contact QIBR