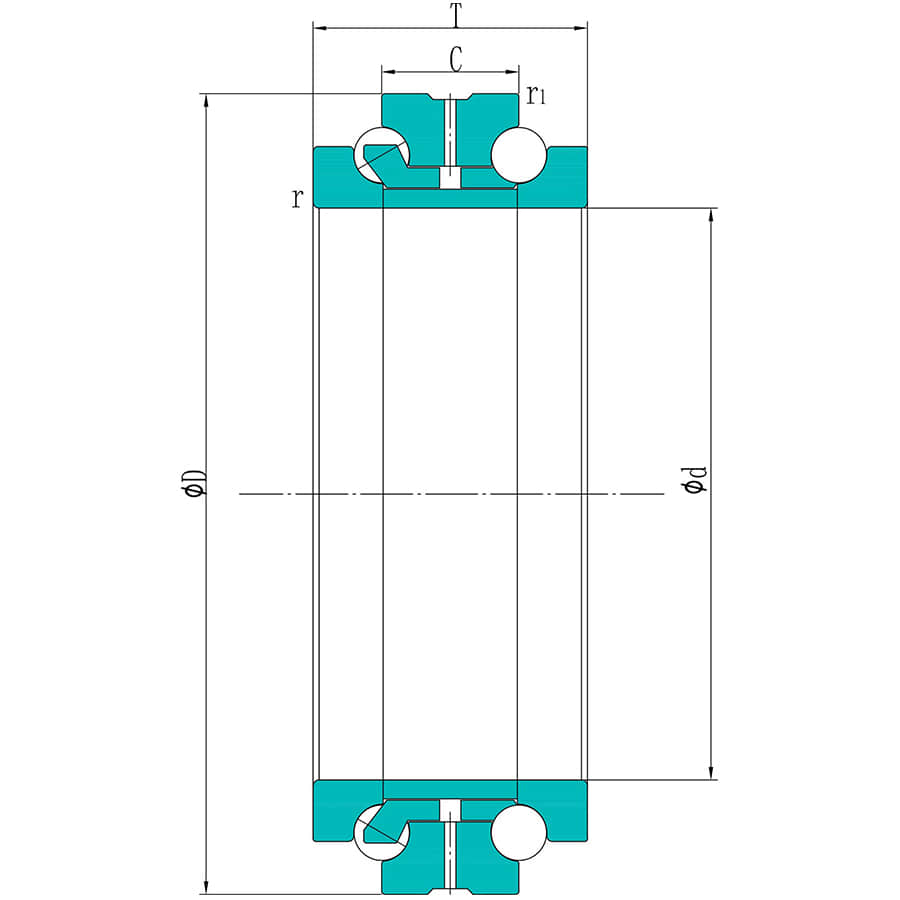

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh,DIN / VDEh

Shaft abutment diameter (das)

140mm-280mm

Outer ring diameter

190mm-380mm

Weight

4.2kg-33.5kg

Material

SKF3, ZGCr15, Stainless Steel, Heat-resistant Steel, Ceramic

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Machine Tool Spindle, Centrifuge, Booster Pump, Oil Pump, Blower, Various Gearboxes, Laboratory Equipment

Pairing method

DB, DF, DT

| NO. | Product | Product Number | Axial dynamic capacities | Axial static capacities | Inner diameter (d) | Mass | Outer diameter (D) | Width (T) |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

140TAC29D+L | 91.5 KN | 365 KN | 140 mm | 4.20 kg | 190 mm | 60 mm |

| 2 |

|

140TAC20D+L | 145.0 KN | 525 KN | 140 mm | 8.75 kg | 210 mm | 84 mm |

| 3 |

|

150TAC29D+L | 116.0 KN | 465 KN | 150 mm | 6.00 kg | 210 mm | 72 mm |

| 4 |

|

150TAC20D+L | 172.0 KN | 620 KN | 150 mm | 10.70 kg | 225 mm | 90 mm |

| 5 |

|

160TAC29D+L | 188.0 KN | 490 KN | 160 mm | 7.00 kg | 220 mm | 72 mm |

| 6 |

|

160TAC20D+L | 185.0 KN | 680 KN | 160 mm | 13.00 kg | 240 mm | 96 mm |

| 7 |

|

170TAC29D+L | 120.0 KN | 520 KN | 170 mm | 7.35 kg | 230 mm | 72 mm |

| 8 |

|

170TAC20D+L | 218.0 KN | 810 KN | 170 mm | 17.70 kg | 260 mm | 108 mm |

| 9 |

|

180TAC29D+L | 158.0 KN | 655 KN | 180 mm | 10.70 kg | 250 mm | 84 mm |

| 10 |

|

190TAC29D+L | 161.0 KN | 695 KN | 190 mm | 11.20 kg | 260 mm | 84 mm |

| 11 |

|

190TAC20D+L | 285.0 KN | 1060 KN | 190 mm | 24.40 kg | 290 mm | 120 mm |

| 12 |

|

200TAC29D+L | 204.0 KN | 855 KN | 200 mm | 15.70 kg | 280 mm | 96 mm |

| 13 |

|

200TAC20D+L | 315.0 KN | 1180 KN | 200 mm | 31.50 kg | 310 mm | 132 mm |

| 14 |

|

220TAC29D+L | 210.0 KN | 930 KN | 220 mm | 17.00 kg | 300 mm | 96 mm |

| 15 |

|

240TAC29D+L | 213.0 KN | 980 KN | 240 mm | 18.30 kg | 320 mm | 96 mm |

| 16 |

|

260TAC29D+L | 315.0 KN | 1390 KN | 260 mm | 31.50 kg | 360 mm | 120 mm |

| 17 |

|

280TAC29D+L | 320.0 KN | 1470 KN | 280 mm | 33.50 kg | 380 mm | 120 mm |

Characteristics and Advantages of QIBR Double-direction Thrust Angular Contact Ball Bearings

QIBR double-direction thrust angular contact ball bearings have multiple significant characteristics and advantages and solve key problems in various fields, mainly reflected in the following aspects:

1. QIBR double-direction thrust angular contact ball bearings have the characteristics of high precision and high rigidity

The precision of double-row thrust angular contact ball bearings is much higher than that of ordinary thrust ball bearings, and the acceptable speed is also higher. This makes it very suitable for use as a spindle bearing that requires high rotational precision. At the same time, it also has good rigidity. Under load, the elastic deformation is small, which is conducive to improving production efficiency and equipment precision.

2. QIBR double-direction thrust angular contact ball bearings have the characteristic of optimized design structure

Double-row angular contact ball bearings usually consist of an outer ring and two inner rings. Its contact angle is generally 30° to 60°, which affects its load-carrying capacity and application scenarios. The larger the contact angle, the stronger the axial load-carrying capacity of the bearing.

3. QIBR double-direction thrust angular contact ball bearings can withstand bidirectional axial loads

The design of double-row thrust angular contact ball bearings enables it to withstand bidirectional axial loads. That is to say, no matter whether the direction of the axial load is positive or negative, the bearing can bear it stably. This makes it very suitable for applications that need to bear bidirectional axial loads, such as machine tool spindles, high-frequency motors, etc.

4. QIBR double-row standard angular contact ball bearings have the characteristics of low temperature rise and high speed

Double-row thrust angular contact ball bearings adopt optimized design and have low temperature rise during high-speed operation. At the same time, its maximum speed is also very high, which can meet high-speed application occasions.

Performance Improvement and Solutions for QIBR Double-direction Thrust Angular Contact Ball Bearings

The performance improvement and solutions for double-row standard angular contact ball bearings mainly involve optimized design, material selection, and load and stiffness management. Here are some key points.

1. Effectively improve material performance

For the production of double-direction thrust angular contact ball bearings, high-quality steel is selected to manufacture inner and outer rings and balls. Through processes such as vacuum heat treatment, the surface hardness and material properties are improved, thereby improving the bearing's load-carrying capacity and service life.

2. Optimize internal structure design

Double-direction thrust angular contact ball bearings use means such as finite element analysis to optimize the structural parameters of double-direction thrust angular contact ball bearings, such as contact angle, curvature radius of inner and outer rings, etc., to improve the axial stiffness and load-carrying capacity of the bearing. Through the multi-objective optimization design method, the internal structure of angular contact ball bearings is optimized to improve their working performance. Under the premise of keeping the standard values of inner diameter, outer diameter and width unchanged, the optimized design can significantly improve its rated dynamic load and static load.

3. Improve manufacturing accuracy

The production of double-direction thrust angular contact ball bearings adopts advanced foreign processing equipment and processes, such as precision grinding and superfinishing grinding, to improve the geometric accuracy of inner and outer rings and balls, reduce processing errors, thereby improving the rotational accuracy and operational stability of the bearing and ensuring the protrusion and roughness of the bearing.

4. Improve lubrication performance

Adopting high-performance materials and appropriate lubricants for double-direction thrust angular contact ball bearings can reduce friction and wear, thereby improving the service life and reliability of the bearing. Especially in high-speed and high-load applications, choosing an appropriate lubrication method is particularly important.

5. Load management

When designing double double-direction thrust angular contact ball bearings, it is necessary to consider its ability to withstand radial loads and bidirectional axial loads. Reasonable load distribution can improve the overall performance and service life of the bearing.

6. Personalized design

According to the application requirements of double-direction thrust angular contact ball bearings in different occasions, personalized structural size solutions are provided to meet specific performance requirements. This method not only enriches the standards of bearings but also provides effective guidance for manufacturers to meet users' personalized needs.

In short, by optimizing materials, internal structure, manufacturing accuracy, lubrication and personalized design and other measures, the performance of double-direction thrust angular contact ball bearings can be significantly improved to meet increasingly demanding application requirements.