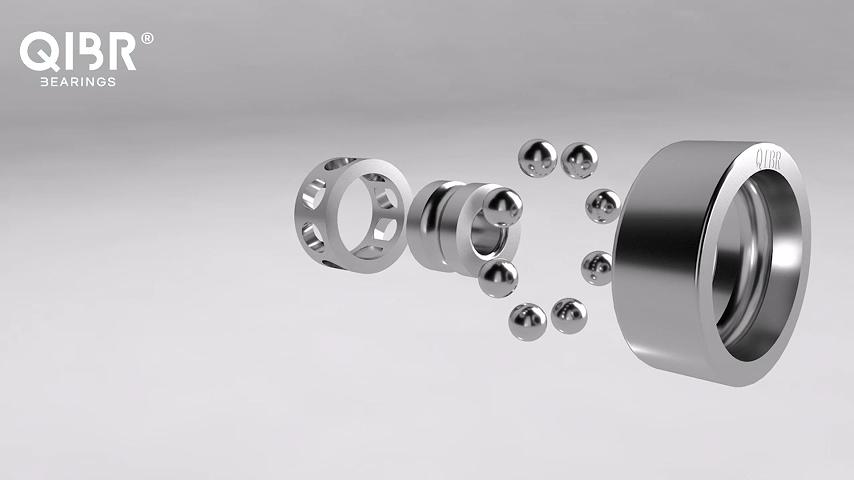

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh,DIN / VDEh

Inner ring diameter

3mm-50mm

Outer ring diameter

10mm-110mm

Weight

1.6g-1140g

Material

GCr15, 52100, 100Cr6, SUJ2, Stainless Steel, Ceramic

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Machine tool spindle, centrifuge, booster pump, oil pump, blower, various gearboxes, laboratory equipment

Pairing method

DB, DF, DT, DBD, DBB, SU

| NO. | Product | Product Number | Basic dynamic load rating | Basic static load rating | Inner diameter (d) | Mass | Outer diameter (D) | Width (B) |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

723C | 650 N | 240 N | 3 mm | 1.6 g | 10 mm | 4 mm |

| 2 |

|

719/4C | 720 N | 290 N | 4 mm | 1.8 g | 11 mm | 4 mm |

| 3 |

|

724C | 1330 N | 510 N | 4 mm | 3.2 g | 13 mm | 5 mm |

| 4 |

|

719/5C | 1090 N | 440 N | 5 mm | 2.4 g | 13 mm | 4 mm |

| 5 |

|

705C | 1550 N | 520 N | 5 mm | 3.5 g | 14 mm | 5 mm |

| 6 |

|

725C | 1770 N | 690 N | 5 mm | 4.8 g | 16 mm | 5 mm |

| 7 |

|

719/6C | 1306 N | 540 N | 6 mm | 3.8 g | 15 mm | 5 mm |

| 8 |

|

706C | 2030 N | 770 N | 6 mm | 6 g | 17 mm | 6 mm |

| 9 |

|

726C | 2770 N | 1260 N | 6 mm | 8.1 g | 19 mm | 6 mm |

| 10 |

|

719/7C | 1620 N | 720 N | 7 mm | 5.2 g | 17 mm | 5 mm |

| 11 |

|

707C | 2400 N | 1020 N | 7 mm | 7.9 g | 19 mm | 6 mm |

| 12 |

|

727C | 3360 N | 1400 N | 7 mm | 13 g | 22 mm | 7 mm |

| 13 |

|

719/8C | 2000 N | 870 N | 8 mm | 7.3 g | 19 mm | 6 mm |

| 14 |

|

708C | 3360 N | 1400 N | 8 mm | 12 g | 22 mm | 7 mm |

| 15 |

|

728C | 4100 N | 1600 N | 8 mm | 17 g | 24 mm | 8 mm |

| 16 |

|

719/9C | 2500 N | 1100 N | 9 mm | 8.2 g | 20 mm | 6 mm |

| 17 |

|

709C | 3900 N | 1500 N | 9 mm | 15 g | 24 mm | 7 mm |

| 18 |

|

729C | 4900 N | 2100 N | 9 mm | 20 g | 26 mm | 8 mm |

| 19 |

|

7800C | 1900 N | 980 N | 10 mm | 54 g | 19 mm | 5 mm |

| 20 |

|

7900C | 3150 N | 1520 N | 10 mm | 90 g | 22 mm | 6 mm |

| 21 |

|

7000C | 5500 N | 2490 N | 10 mm | 19 g | 26 mm | 8 mm |

| 22 |

|

7300C | 9300 N | 4300 N | 10 mm | 53 g | 35 mm | 11 mm |

| 23 |

|

7801C | 2000 N | 1400 N | 12 mm | 60 g | 21 mm | 5 mm |

| 24 |

|

7901C | 3550 N | 1860 N | 12 mm | 11 g | 24 mm | 6 mm |

| 25 |

|

7001C | 6100 N | 2900 N | 12 mm | 21 g | 28 mm | 8 mm |

| 26 |

|

7301C | 10800 N | 4900 N | 12 mm | 63 g | 37 mm | 12 mm |

| 27 |

|

7802C | 2200 N | 1800 N | 15 mm | 70 g | 24 mm | 5 mm |

| 28 |

|

7902C | 4800 N | 3400 N | 15 mm | 20 g | 28 mm | 7 mm |

| 29 |

|

7002C | 6550 N | 3400 N | 15 mm | 26 g | 32 mm | 9 mm |

| 30 |

|

7302C | 13300 N | 6805 N | 15 mm | 85 g | 42 mm | 13 mm |

| 31 |

|

7803C | 2300 N | 1900 N | 17 mm | 80 g | 26 mm | 5 mm |

| 32 |

|

7903C | 5250 N | 2940 N | 17 mm | 107 g | 30 mm | 7 mm |

| 33 |

|

7003C | 6960 N | 3800 N | 17 mm | 39 g | 35 mm | 10 mm |

| 34 |

|

7303C | 15700 N | 8250 N | 17 mm | 109 g | 47 mm | 14 mm |

| 35 |

|

7804C | 3900 N | 3400 N | 20 mm | 18 g | 32 mm | 7 mm |

| 36 |

|

7904C | 7400 N | 5800 N | 20 mm | 20 g | 37 mm | 9 mm |

| 37 |

|

7004C | 1170 N | 6550 N | 20 mm | 71 g | 42 mm | 12 mm |

| 38 |

|

7304C | 18500 N | 9950 N | 20 mm | 140 g | 52 mm | 15 mm |

| 39 |

|

7805C | 3900 N | 3300 N | 25 mm | 123 g | 37 mm | 7 mm |

| 40 |

|

7905C | 8150 N | 5700 N | 25 mm | 326 g | 42 mm | 9 mm |

| 41 |

|

7005C | 1230 N | 7400 N | 25 mm | 78 g | 47 mm | 12 mm |

| 42 |

|

7305C | 22900 N | 13300 N | 25 mm | 243 g | 62 mm | 17 mm |

| 43 |

|

7806C | 4400 N | 3650 N | 30 mm | 129 g | 42 mm | 7 mm |

| 44 |

|

7906C | 8700 N | 6250 N | 30 mm | 49 g | 47 mm | 9 mm |

| 45 |

|

7006C | 13590 N | 9890 N | 30 mm | 130 g | 55 mm | 13 mm |

| 46 |

|

7306B | 27600 N | 17400 N | 30 mm | 141 g | 72 mm | 19 mm |

| 47 |

|

7807C | 4600 N | 5500 N | 35 mm | 29 g | 47 mm | 7 mm |

| 48 |

|

7907C | 12700 N | 9150 N | 35 mm | 74 g | 55 mm | 10 mm |

| 49 |

|

7007C | 20100 N | 13700 N | 35 mm | 151 g | 62 mm | 14 mm |

| 50 |

|

7307B | 32500 N | 20200 N | 35 mm | 475 g | 80 mm | 21 mm |

| 51 |

|

7808C | 4800 N | 6200 N | 40 mm | 32 g | 52 mm | 7 mm |

| 52 |

|

7908C | 15900 N | 11700 N | 40 mm | 109 g | 62 mm | 12 mm |

| 53 |

|

7008C | 21600 N | 15900 N | 40 mm | 189 g | 68 mm | 15 mm |

| 54 |

|

7308B | 39700 N | 25200 N | 40 mm | 657 g | 90 mm | 23 mm |

| 55 |

|

7809C | 4900 N | 6700 N | 45 mm | 400 g | 58 mm | 7 mm |

| 56 |

|

7909C | 16800 N | 13400 N | 45 mm | 129 g | 68 mm | 12 mm |

| 57 |

|

7009C | 25600 N | 19300 N | 45 mm | 238 g | 75 mm | 16 mm |

| 58 |

|

7309C | 64000 N | 43000 N | 45 mm | 415 g | 100 mm | 25 mm |

| 59 |

|

7810C | 74000 N | 10000 N | 50 mm | 52 g | 65 mm | 7 mm |

| 60 |

|

7910C | 17700 N | 15000 N | 50 mm | 130 g | 72 mm | 12 mm |

| 61 |

|

7010C | 27300 N | 21900 N | 50 mm | 259 g | 80 mm | 16 mm |

| 62 |

|

7310B | 64400 N | 44300 N | 50 mm | 1140 g | 110 mm | 27 mm |

Characteristics and advantages of QIBR micro angular contact ball bearings

QIBR micro angular contact ball bearings have solved multiple key problems in various fields, mainly reflected in the following aspects;

1. QIBR micro angular contact ball bearings have strong load capacity

Micro angular contact ball bearings can be both radial and axial loads, and can even withstand pure axial loads. This ability makes it perform excellently in applications that require bearing multi-directional loads. The design of contact angle directly affects its axial load capacity, and the larger the contact angle, the stronger the axial load capacity it can withstand.

2. QIBR micro angular contact ball bearings have excellent operational stability

Micro angular contact ball bearings are usually used in pairs to improve operational stability. By pairing, micro angular contact ball bearings can provide higher axial rigidity and effectively reduce or eliminate radial clearances, which helps improve equipment accuracy and stability. This is crucial for applications that require high precision and stability, such as machine tool spindles or high-precision rotating equipment.

3. The lifespan of QIBR micro angular contact ball bearings has been greatly improved

The service life of QIBR micro angular contact ball bearings can be significantly improved through reasonable installation and preloading. The correct installation method can reduce additional stress, thereby reducing wear and extending the service life of bearings.

4. QIBR miniature angular contact ball bearings can effectively control noise

Micro angular contact ball bearings have made significant progress in noise control. High precision QIBR micro angular contact ball bearings can effectively reduce noise during operation and improve overall equipment performance through precise installation, appropriate lubrication, and advanced monitoring systems.

5. QIBR micro angular contact ball bearings have high cost-effectiveness

The design of micro angular contact ball bearings allows for efficient load support in relatively small spaces. Compared to combinations of multiple single row bearings, using double row or paired designs can reduce costs while improving rigidity and stability.

In summary, micro angular contact ball bearings have solved various problems in high-speed and high load applications through their superior load capacity, motion stability, long service life, noise control, and cost-effectiveness.

Performance improvement and solution of QIBR micro angular contact ball bearings

1. Effectively improve material performance

Micro angular contact ball bearings use high-quality steel to manufacture the inner and outer rings and balls during production, and improve surface hardness and material properties through processes such as vacuum heat treatment, enhancing the bearing's load-bearing capacity and service life.

2. Optimize internal structural design

The structural parameters of micro angular contact ball bearings are optimized through finite element analysis and other methods. For example, by adjusting the contact angle, the curvature radius of the inner and outer rings, etc., the axial stiffness and load-bearing capacity of the bearing can be improved.

3. Improve manufacturing accuracy

Adopting advanced processing equipment and techniques from abroad, such as precision grinding, ultra precision grinding, etc., to improve the geometric accuracy of the inner and outer rings and balls, reduce processing errors, improving the rotational accuracy and operational stability of the bearings. In addition, it can also ensure the protrusion and roughness of the bearings.

4. Improve lubrication performance

Select high-performance lubricating grease, such as aviation lubricating grease, and adopt sealing measures, such as double-sided contact sealing rings, to reduce grease loss, improve the lubrication performance of micro angular contact ball bearings, and reduce friction and wear.

5. Optimize pre-tightening design

By optimizing the magnitude and method of pre tightening force, such as using elastic washers for pre tightening, the length change of the shaft after heating and the radial clearance change caused by the temperature difference between the inner and outer rings will not affect the pre tightening deformation, while reducing internal stress and extending the service life.

In summary, by optimizing materials, structures, manufacturing processes, lubrication, and pre tensioning designs, the performance of micro angular contact ball bearings can be significantly improved to meet increasingly demanding application requirements.

The main application areas of QIBR micro angular contact ball bearings

QIBR micro angular contact ball bearings are widely used in medical equipment, precision instruments, power tools, electronic equipment, automation equipment, instrumentation, aerospace and other fields. Its compact design and high performance make it suitable for applications that require high space and precision.