Image may differ from product. See technical specification for details.

Search for the bearing model you need

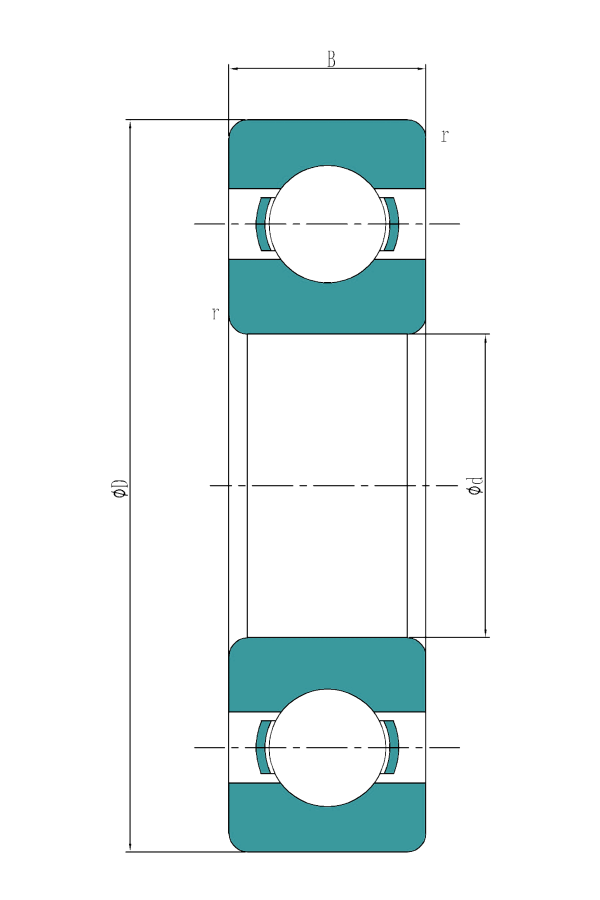

Shaft abutment diameter (da)

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Material

Silicon Nitride, Zirconium Oxide, Aluminum Oxide, Silicon Carbide

Inner ring diameter

4mm-20mm

Outer ring diameter

13mm-32mm

Weight

0.55g-8.8g

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Machine tool spindle, centrifuge, booster pump, oil pump, blower, various gearboxes, laboratory equipment

| NO. | Product | Product Number | Basic load rating | Inner diameter (d) | Mass | Outer diameter (D) | Chamfer dimension (r) | Width (B) |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

624 | 2.84 N | 4 mm | 0.55 g | 13 mm | 0.2 mm | 5 mm |

| 2 |

|

625 | 5.88 N | 5 mm | 0.9 g | 16 mm | 0.3 mm | 5 mm |

| 3 |

|

605 | 3.92 N | 5 mm | 0.65 g | 14 mm | 0.3 mm | 5 mm |

| 4 |

|

626 | 6.86 N | 6 mm | 1.5 g | 19 mm | 0.3 mm | 6 mm |

| 5 |

|

606 | 6.86 N | 6 mm | 1.2 g | 17 mm | 0.6 mm | 6 mm |

| 6 |

|

696 | 4.9 N | 6 mm | 0.75 g | 15 mm | 0.6 mm | 5 mm |

| 7 |

|

628 | 12.74 N | 8 mm | 3.2 g | 24 mm | 0.2 mm | 8 mm |

| 8 |

|

608 | 12.74 N | 8 mm | 2.4 g | 22 mm | 0.3 mm | 7 mm |

| 9 |

|

698 | 5.88 N | 8 mm | 1.3 g | 19 mm | 0.3 mm | 6 mm |

| 10 |

|

6200 | 21.56 N | 10 mm | 5.6 g | 30 mm | 0.3 mm | 9 mm |

| 11 |

|

6000 | 12.74 N | 10 mm | 3.5 g | 26 mm | 0.6 mm | 8 mm |

| 12 |

|

6900 | 12.74 N | 10 mm | 1.9 g | 22 mm | 1 mm | 6 mm |

| 13 |

|

6201 | 24.50 N | 12 mm | 7 g | 32 mm | 0.2 mm | 10 mm |

| 14 |

|

6001 | 15.68 N | 12 mm | 4 g | 28 mm | 0.3 mm | 8 mm |

| 15 |

|

6901 | 11.76 N | 12 mm | 1.9 g | 24 mm | 0.3 mm | 6 mm |

| 16 |

|

6202 | 29.40 N | 15 mm | 8.8 g | 35 mm | 0.3 mm | 11 mm |

| 17 |

|

6002 | 24.50 N | 15 mm | 5.7 g | 32 mm | 0.6 mm | 9 mm |

| 18 |

|

6902 | 15.68 N | 15 mm | 3 g | 28 mm | 1 mm | 7 mm |

| 19 |

|

6203 | 39.20 N | 17 mm | 12.8 g | 40 mm | 0.2 mm | 12 mm |

| 20 |

|

6003 | 29.40 N | 17 mm | 7.3 g | 35 mm | 0.3 mm | 10 mm |

| 21 |

|

6903 | 19.60 N | 17 mm | 3.3 g | 30 mm | 0.3 mm | 7 mm |

| 22 |

|

6204 | 49.00 N | 20 mm | 20 g | 47 mm | 0.3 mm | 14 mm |

| 23 |

|

6004 | 35.28 N | 20 mm | 12.6 g | 42 mm | 0.6 mm | 12 mm |

| 24 |

|

6904 | 32.34 N | 20 mm | 8.8 g | 37 mm | 1 mm | 9 mm |

Features and advantages of QIBR ceramic deep groove ball bearings

QIBR ceramic deep groove ball bearings are engineered to address critical operational demands in various industrial fields, offering the following key advantages:

1. Superior wear resistance

QIBR ceramic bearings exhibit exceptional hardness and wear resistance. Unlike traditional steel bearings, the rolling elements in ceramic bearings are highly durable, particularly in high-load and high-frequency applications.

2. Reduced friction coefficient

Ceramic balls have a lower friction coefficient compared to steel balls. This reduces energy loss, enhances operational efficiency, and minimizes heat generation during high-speed operations.

3. Exceptional corrosion resistance

Ceramic materials resist moisture, acids, alkalis, and other chemicals, making these bearings ideal for harsh environments such as chemical, marine, and food processing industries.

4. Outstanding high-temperature performance

Ceramic materials maintain their strength and hardness at elevated temperatures, often surpassing the tolerance of steel. As a result, QIBR ceramic bearings are widely used in high-temperature applications, including aerospace and metallurgy.

Performance enhancements for QIBR ceramic deep groove ball bearings

1. Improving material purity and uniformity

The performance of ceramic balls directly impacts the overall bearing quality. Enhancing material purity increases hardness, wear resistance, and corrosion resistance, thereby extending bearing life.

2. Optimizing microstructure

Refining the grain structure of ceramic materials enhances their compressive strength, impact resistance, and internal stress distribution, reducing the likelihood of material failure or performance degradation.

3. Utilizing dry lubrication

Ceramic bearings are particularly suited for environments requiring oil-free lubrication or extreme conditions like vacuum, low temperatures, or high temperatures. Choosing the right dry lubricant can further improve performance under such circumstances.

4. Improving groove design

Enhancements to the deep groove design, such as adjusting groove depth or increasing the contact area between the inner and outer rings, can optimize load capacity and improve operational stability.

Primary application fields of QIBR ceramic deep groove ball bearings

1. High-speed machinery

With their low friction coefficient and high hardness, ceramic bearings reduce frictional heat generation, making them ideal for high-speed machinery.

2. Precision instruments and equipment

The low friction and noise characteristics of ceramic bearings ensure high accuracy and stability in precision instruments.

3. Electronics

Ceramic bearings help reduce heat generation, extend the lifespan of electronic devices, and are lightweight, making them suitable for applications with strict weight requirements.

4. Medical equipment

Ceramic materials are rust-resistant and corrosion-resistant, making them ideal for demanding medical environments. Additionally, their low friction reduces mechanical wear and heat generation, enhancing equipment reliability and stability.