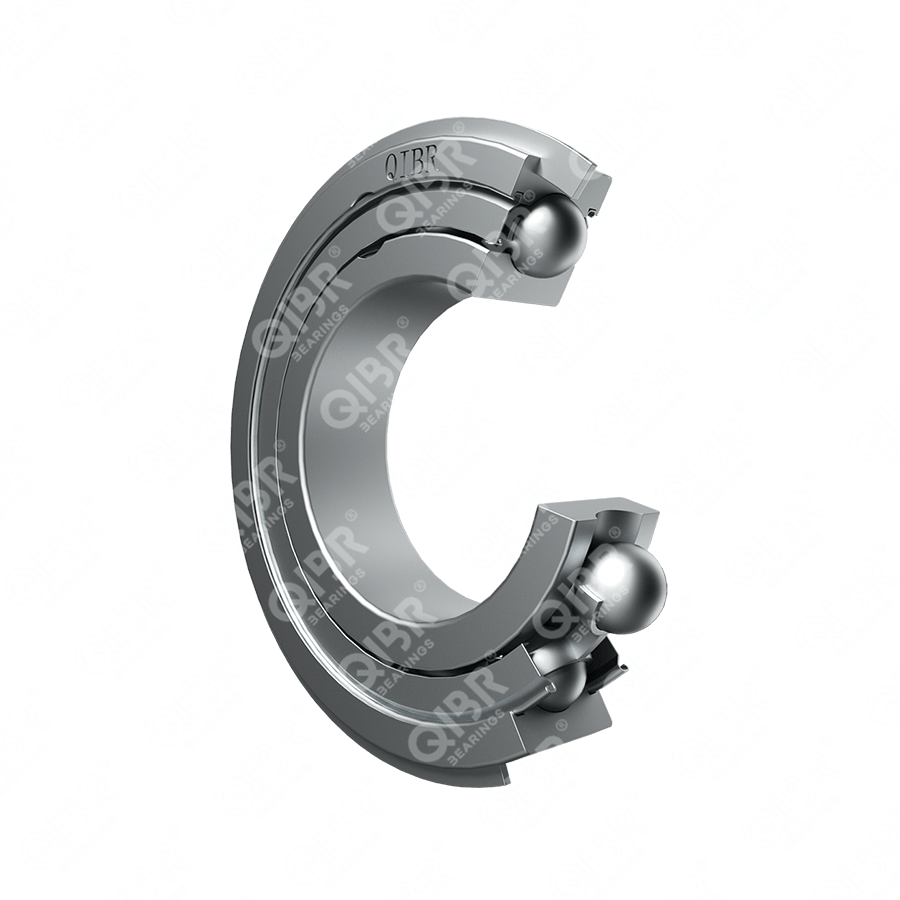

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Material

GCr15、5200、100Cr6、SUJ2

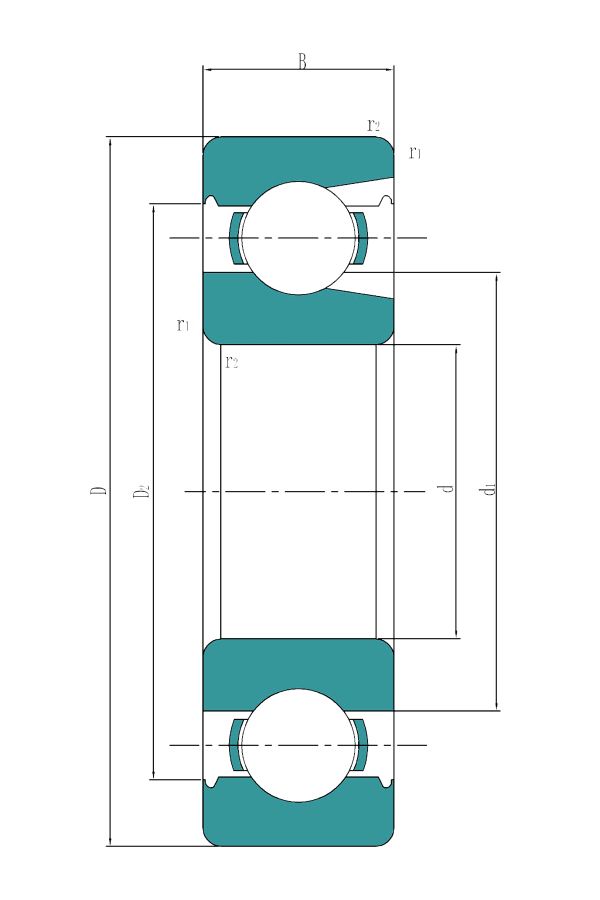

Inner ring diameter

25mm-110mm

Outer ring diameter

62mm-180mm

Weight

0.24kg-5.4kg

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Machine tool spindle, centrifuge, booster pump, oil pump, blower, various gearboxes, laboratory equipment

| NO. | Product | Product Number | Basic dynamic load rating | Basic static load rating | Inner diameter (d) | Outer diameter (D) | Reference speed | Width (B) |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

305 | 22.9 KN | 15.6 KN | 25 mm | 62 mm | 20000 r/min | 17 mm |

| 2 |

|

305 NR | 22.9 KN | 15.6 KN | 25 mm | 62 mm | 20000 r/min | 17 mm |

| 3 |

|

305 Z | 22.9 KN | 15.6 KN | 25 mm | 62 mm | 20000 r/min | 17 mm |

| 4 |

|

305 ZNR | 22.9 KN | 15.6 KN | 25 mm | 62 mm | 20000 r/min | 17 mm |

| 5 |

|

305 2Z | 22.9 KN | 15.6 KN | 25 mm | 62 mm | 20000 r/min | 17 mm |

| 6 |

|

305 2ZNR | 22.9 KN | 15.6 KN | 25 mm | 62 mm | 20000 r/min | 17 mm |

| 7 |

|

206 | 20.9 KN | 16.3 KN | 30 mm | 62 mm | 20000 r/min | 16 mm |

| 8 |

|

206 NR | 20.9 KN | 16.3 KN | 30 mm | 62 mm | 20000 r/min | 16 mm |

| 9 |

|

206 Z | 20.9 KN | 16.3 KN | 30 mm | 62 mm | 20000 r/min | 16 mm |

| 10 |

|

206 ZNR | 20.9 KN | 16.3 KN | 30 mm | 62 mm | 20000 r/min | 16 mm |

| 11 |

|

206 2Z | 20.9 KN | 16.3 KN | 30 mm | 62 mm | 20000 r/min | 16 mm |

| 12 |

|

206 2ZNR | 20.9 KN | 16.3 KN | 30 mm | 62 mm | 20000 r/min | 16 mm |

| 13 |

|

306 | 29.7 KN | 21.6 KN | 30 mm | 72 mm | 18000 r/min | 19 mm |

| 14 |

|

306 NR | 29.7 KN | 21.6 KN | 30 mm | 72 mm | 18000 r/min | 19 mm |

| 15 |

|

306 Z | 29.7 KN | 21.6 KN | 30 mm | 72 mm | 18000 r/min | 19 mm |

| 16 |

|

306 ZNR | 29.7 KN | 21.6 KN | 30 mm | 72 mm | 18000 r/min | 19 mm |

| 17 |

|

306 2Z | 29.7 KN | 21.6 KN | 30 mm | 72 mm | 18000 r/min | 19 mm |

| 18 |

|

306 2ZNR | 29.7 KN | 21.6 KN | 30 mm | 72 mm | 18000 r/min | 19 mm |

| 19 |

|

207 | 27.5 KN | 22 KN | 35 mm | 72 mm | 17000 r/min | 17 mm |

| 20 |

|

207 NR | 27.5 KN | 22 KN | 35 mm | 72 mm | 17000 r/min | 17 mm |

| 21 |

|

207 Z | 27.5 KN | 22 KN | 35 mm | 72 mm | 17000 r/min | 17 mm |

| 22 |

|

207 ZNR | 27.5 KN | 22 KN | 35 mm | 72 mm | 17000 r/min | 17 mm |

| 23 |

|

207 2Z | 27.5 KN | 22 KN | 35 mm | 72 mm | 17000 r/min | 17 mm |

| 24 |

|

207 2ZNR | 27.5 KN | 22 KN | 35 mm | 72 mm | 17000 r/min | 17 mm |

| 25 |

|

307 | 34.7 KN | 26.5 KN | 35 mm | 80 mm | 16000 r/min | 21 mm |

| 26 |

|

307 NR | 34.7 KN | 26.5 KN | 35 mm | 80 mm | 16000 r/min | 21 mm |

| 27 |

|

307 Z | 34.7 KN | 26.5 KN | 35 mm | 80 mm | 16000 r/min | 21 mm |

| 28 |

|

307 ZNR | 34.7 KN | 26.5 KN | 35 mm | 80 mm | 16000 r/min | 21 mm |

| 29 |

|

307 2Z | 34.7 KN | 26.5 KN | 35 mm | 80 mm | 16000 r/min | 21 mm |

| 30 |

|

307 2ZNR | 34.7 KN | 26.5 KN | 35 mm | 80 mm | 16000 r/min | 21 mm |

| 31 |

|

208 | 33.6 KN | 27 KN | 40 mm | 80 mm | 15000 r/min | 18 mm |

| 32 |

|

208 NR | 33.6 KN | 27 KN | 40 mm | 80 mm | 15000 r/min | 18 mm |

| 33 |

|

208 Z | 33.6 KN | 27 KN | 40 mm | 80 mm | 15000 r/min | 18 mm |

| 34 |

|

208 ZNR | 33.6 KN | 27 KN | 40 mm | 80 mm | 15000 r/min | 18 mm |

| 35 |

|

208 2Z | 33.6 KN | 27 KN | 40 mm | 80 mm | 15000 r/min | 18 mm |

| 36 |

|

208 2ZNR | 33.6 KN | 27 KN | 40 mm | 80 mm | 15000 r/min | 18 mm |

| 37 |

|

308 | 45.7 KN | 36 KN | 40 mm | 90 mm | 14000 r/min | 23 mm |

| 38 |

|

308 NR | 45.7 KN | 36 KN | 40 mm | 90 mm | 14000 r/min | 23 mm |

| 39 |

|

308 Z | 45.7 KN | 36 KN | 40 mm | 90 mm | 14000 r/min | 23 mm |

| 40 |

|

308 ZNR | 45.7 KN | 36 KN | 40 mm | 90 mm | 14000 r/min | 23 mm |

| 41 |

|

309 NR | 55 KN | 44 KN | 45 mm | 100 mm | 13000 r/min | 25 mm |

| 42 |

|

308 2Z | 45.7 KN | 36 KN | 40 mm | 90 mm | 14000 r/min | 23 mm |

| 43 |

|

309 Z | 55 KN | 44 KN | 45 mm | 100 mm | 13000 r/min | 25 mm |

| 44 |

|

308 2ZNR | 45.7 KN | 36 KN | 40 mm | 90 mm | 14000 r/min | 23 mm |

| 45 |

|

309 ZNR | 55 KN | 44 KN | 45 mm | 100 mm | 13000 r/min | 25 mm |

| 46 |

|

209 | 35.2 KN | 30 KN | 45 mm | 85 mm | 14000 r/min | 19 mm |

| 47 |

|

309 2Z | 55 KN | 44 KN | 45 mm | 100 mm | 13000 r/min | 25 mm |

| 48 |

|

209 NR | 35.2 KN | 30 KN | 45 mm | 85 mm | 14000 r/min | 19 mm |

| 49 |

|

309 2ZNR | 55 KN | 44 KN | 45 mm | 100 mm | 13000 r/min | 25 mm |

| 50 |

|

209 Z | 35.2 KN | 30 KN | 45 mm | 85 mm | 14000 r/min | 19 mm |

| 51 |

|

210 | 39.1 KN | 34.5 KN | 50 mm | 90mm | 13000 r/min | 20 mm |

| 52 |

|

210 NR | 39.1 KN | 34.5 KN | 50 mm | 90 mm | 13000 r/min | 20 mm |

| 53 |

|

209 ZNR | 35.2 KN | 30 KN | 45 mm | 85 mm | 14000 r/min | 19 mm |

| 54 |

|

209 2Z | 35.2 KN | 30 KN | 45 mm | 85 mm | 14000 r/min | 19 mm |

| 55 |

|

210 Z | 39.1 KN | 34.5 KN | 50 mm | 90 mm | 13000 r/min | 20 mm |

| 56 |

|

209 2ZNR | 35.2 KN | 30 KN | 45 mm | 85 mm | 14000 r/min | 19 mm |

| 57 |

|

210 ZNR | 39.1 KN | 34.5 KN | 50 mm | 90 mm | 13000 r/min | 20 mm |

| 58 |

|

210 2Z | 39.1 KN | 34.5 KN | 50 mm | 90 mm | 13000 r/min | 20 mm |

| 59 |

|

309 | 55 KN | 44 KN | 45 mm | 100 mm | 13000 r/min | 25 mm |

| 60 |

|

210 2ZNR | 39.1 KN | 34.5 KN | 50 mm | 90 mm | 13000 r/min | 20 mm |

| 61 |

|

310 | 64.4 KN | 52 KN | 50 mm | 110 mm | 11000 r/min | 27 mm |

| 62 |

|

310 NR | 64.4 KN | 52 KN | 50 mm | 110 mm | 11000 r/min | 27 mm |

| 63 |

|

310 Z | 64.4 KN | 52 KN | 50 mm | 110 mm | 11000 r/min | 27 mm |

| 64 |

|

310 ZNR | 64.4 KN | 52 KN | 50 mm | 110 mm | 11000 r/min | 27 mm |

| 65 |

|

310 2Z | 64.4 KN | 52 KN | 50 mm | 110 mm | 11000 r/min | 27 mm |

| 66 |

|

310 2ZNR | 64.4 KN | 52 KN | 50 mm | 110 mm | 11000 r/min | 27 mm |

| 67 |

|

211 | 48.4 KN | 44 KN | 55 mm | 100 mm | 12000 r/min | 21 mm |

| 68 |

|

211 NR | 48.4 KN | 44 KN | 55 mm | 100 mm | 12000 r/min | 21 mm |

| 69 |

|

211 Z | 48.4 KN | 44 KN | 55 mm | 100 mm | 12000 r/min | 21 mm |

| 70 |

|

211 ZNR | 48.4 KN | 44 KN | 55 mm | 100 mm | 12000 r/min | 21 mm |

| 71 |

|

211 2Z | 48.4 KN | 44 KN | 55 mm | 100 mm | 12000 r/min | 21 mm |

| 72 |

|

211 2ZNR | 48.4 KN | 44 KN | 55 mm | 100 mm | 12000 r/min | 21 mm |

| 73 |

|

311 | 79.2 KN | 67 KN | 55 mm | 120 mm | 10000 r/min | 29 mm |

| 74 |

|

311 NR | 79.2 KN | 67 KN | 55 mm | 120 mm | 10000 r/min | 29 mm |

| 75 |

|

311 Z | 79.2 KN | 67 KN | 55 mm | 120 mm | 10000 r/min | 29 mm |

| 76 |

|

311 ZNR | 79.2 KN | 67 KN | 55 mm | 120 mm | 10000 r/min | 29 mm |

| 77 |

|

311 2Z | 79.2 KN | 67 KN | 55 mm | 120 mm | 10000 r/min | 29 mm |

| 78 |

|

311 2ZNR | 79.2 KN | 67 KN | 55 mm | 120 mm | 10000 r/min | 29 mm |

| 79 |

|

212 | 56.1 KN | 50 KN | 60 mm | 110 mm | 11000 r/min | 22 mm |

| 80 |

|

212 NR | 56.1 KN | 50 KN | 60 mm | 110 mm | 11000 r/min | 22 mm |

| 81 |

|

212 Z | 56.1 KN | 50 KN | 60 mm | 110 mm | 11000 r/min | 22 mm |

| 82 |

|

212 ZNR | 56.1 KN | 50 KN | 60 mm | 110 mm | 11000 r/min | 22 mm |

| 83 |

|

212 2Z | 56.1 KN | 50 KN | 60 mm | 110 mm | 11000 r/min | 22 mm |

| 84 |

|

212 2ZNR | 56.1 KN | 50 KN | 60 mm | 110 mm | 11000 r/min | 22 mm |

| 85 |

|

312 | 91.3 KN | 78 KN | 60 mm | 130 mm | 9500 r/min | 31 mm |

| 86 |

|

312 NR | 91.3 KN | 78 KN | 60 mm | 130 mm | 9500 r/min | 31 mm |

| 87 |

|

312 Z | 91.3 KN | 78 KN | 60 mm | 130 mm | 9500 r/min | 31 mm |

| 88 |

|

312 ZNR | 91.3 KN | 78 KN | 60 mm | 130 mm | 9500 r/min | 31 mm |

| 89 |

|

312 2Z | 91.3 KN | 78 KN | 60 mm | 130 mm | 9500 r/min | 31 mm |

| 90 |

|

312 2ZNR | 91.3 KN | 78 KN | 60 mm | 130 mm | 9500 r/min | 31 mm |

| 91 |

|

213 | 60.5 KN | 58.5 KN | 65 mm | 120 mm | 10000 r/min | 23 mm |

| 92 |

|

213 NR | 60.5 KN | 58.5 KN | 65 mm | 120 mm | 10000 r/min | 23 mm |

| 93 |

|

213 Z | 60.5 KN | 58.5 KN | 65 mm | 120 mm | 10000 r/min | 23 mm |

| 94 |

|

213 ZNR | 60.5 KN | 58.5 KN | 65 mm | 120 mm | 10000 r/min | 23 mm |

| 95 |

|

213 2Z | 60.5 KN | 58.5 KN | 65 mm | 120 mm | 10000 r/min | 23mm |

| 96 |

|

213 2ZNR | 60.5 KN | 58.5 KN | 65 mm | 120 mm | 10000 r/min | 23 mm |

| 97 |

|

313 | 102 KN | 90 KN | 65 mm | 140 mm | 9000 r/min | 33 mm |

| 98 |

|

313 NR | 102 KN | 90 KN | 65 mm | 140 mm | 9000 r/min | 33 mm |

| 99 |

|

313 Z | 102 KN | 90 KN | 65 mm | 140 mm | 9000 r/min | 33 mm |

| 100 |

|

313 ZNR | 102 KN | 90 KN | 65 mm | 140 mm | 9000 r/min | 33 mm |

Features and advantages of QIBR deep groove ball bearings with filling slots

QIBR deep groove ball bearings with filling slots address critical challenges in various industrial applications, with the following key advantages:

1. Higher load capacity:

The primary feature of the filling slot design is the increased load-carrying capacity. By accommodating more rolling elements, the load is distributed over a larger contact area, enabling the bearing to handle higher loads effectively.

2. Enhanced durability

Optimized load distribution increases the durability of the bearing, allowing it to maintain high performance over an extended lifespan.

3. Versatility in demanding applications

This design is particularly well-suited for heavy-duty and prolonged operation, excelling in applications with high load requirements and complex working conditions.

Performance enhancements and solutions for QIBR deep groove ball bearings with filling slots

1. Increased rolling element contact area

The filling slot design ensures a more uniform distribution of rolling elements on the raceways, enhancing the contact area between the balls and the raceways. This effectively allows the bearing to handle greater radial and axial loads compared to standard deep groove ball bearings.

2. Raceway optimization

Enhancing the geometry and precision of the raceways, as well as improving surface smoothness, reduces friction and energy loss, thereby improving operational efficiency.

3. High-quality rolling elements

Improving the surface finish and hardness of the rolling elements reduces friction and wear. Utilizing high-precision rolling elements, such as ceramic balls, significantly enhances the bearing's performance in demanding conditions.

4. Corrosion-resistant design

For challenging environments such as marine or chemical industries, materials like stainless steel, corrosion-resistant coatings, or advanced surface treatments can be used to improve the bearing’s resistance to corrosion.

Primary application fields for QIBR deep groove ball bearings with filling slots

1. Engines

Widely used in automotive engines, particularly high-performance engines. These bearings can withstand significant radial and axial loads, offering superior lubrication and wear resistance to ensure stable operation under high temperatures and heavy loads.

2. Transmission systems

In automotive systems such as transmissions, differentials, and drive shafts, these bearings provide high load capacity and durability, meeting the demands of high-speed and high-load operations.

3. Aerospace engines

These bearings are utilized in aerospace engines and critical components, offering exceptional load-bearing capability and reliable performance under extreme temperatures and high-speed conditions.

4. Heavy machinery

Commonly used in cranes, excavators, hydraulic equipment, and other heavy machinery that operate under heavy loads and challenging conditions. These bearings enhance load-carrying capacity and extend equipment lifespan.

5. Washing Machines

Applied in motor-driven systems of washing machines, these bearings effectively handle heavy loads and high-speed operations while minimizing noise.

6. Power tools

In power tools, these bearings are capable of handling significant axial and radial loads. They are especially effective in high-speed, vibration-intensive environments, maintaining low friction and providing longer service life with improved operational efficiency.