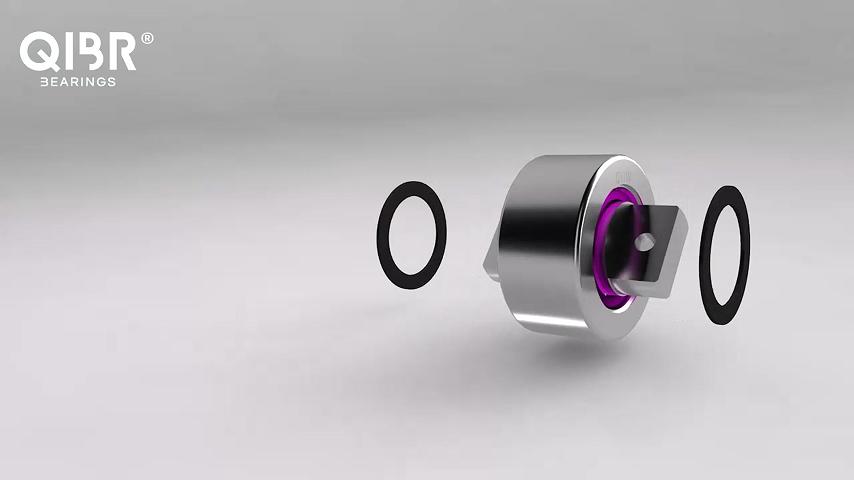

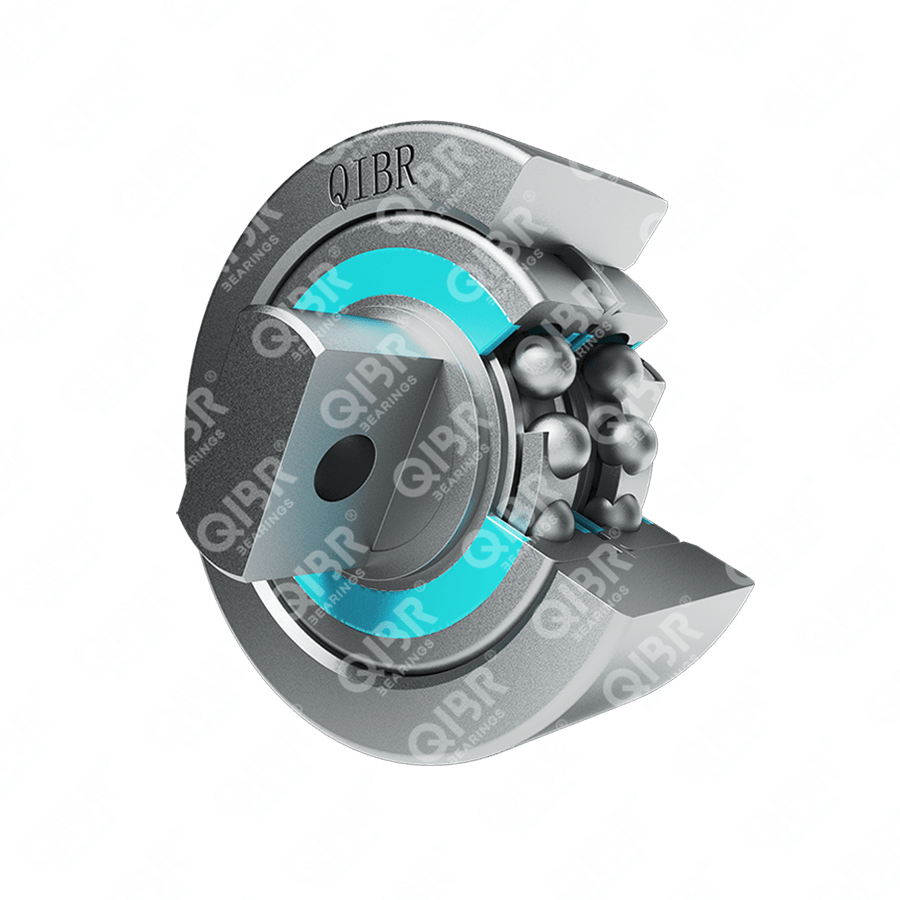

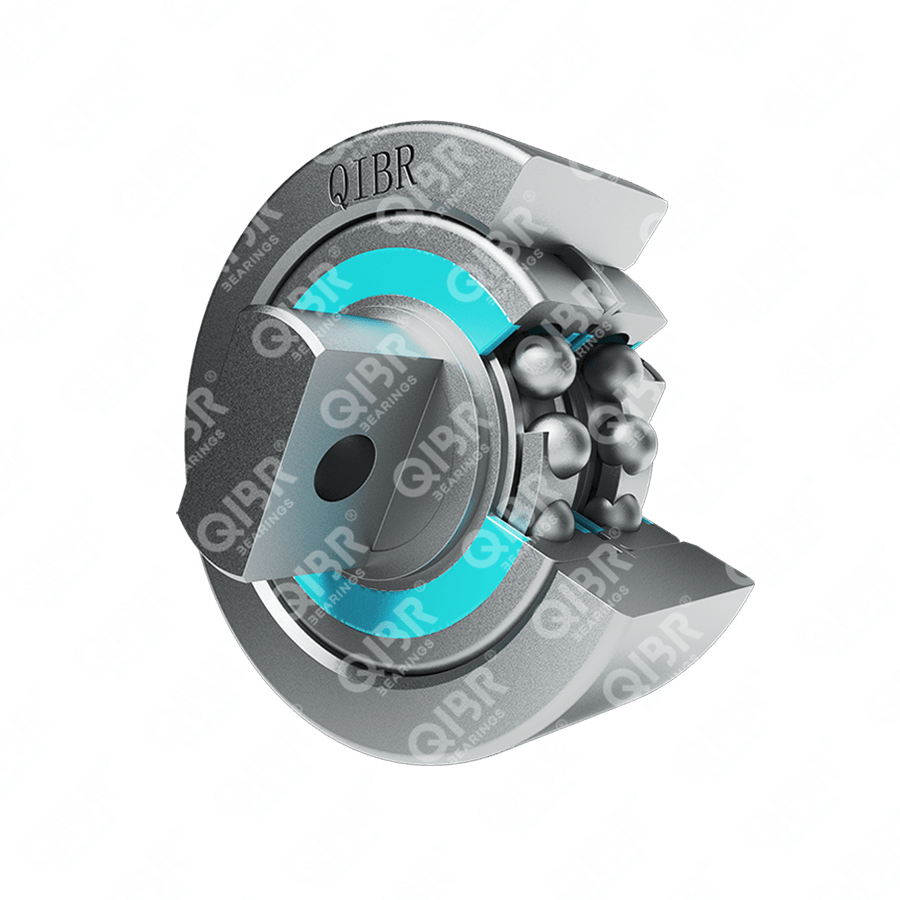

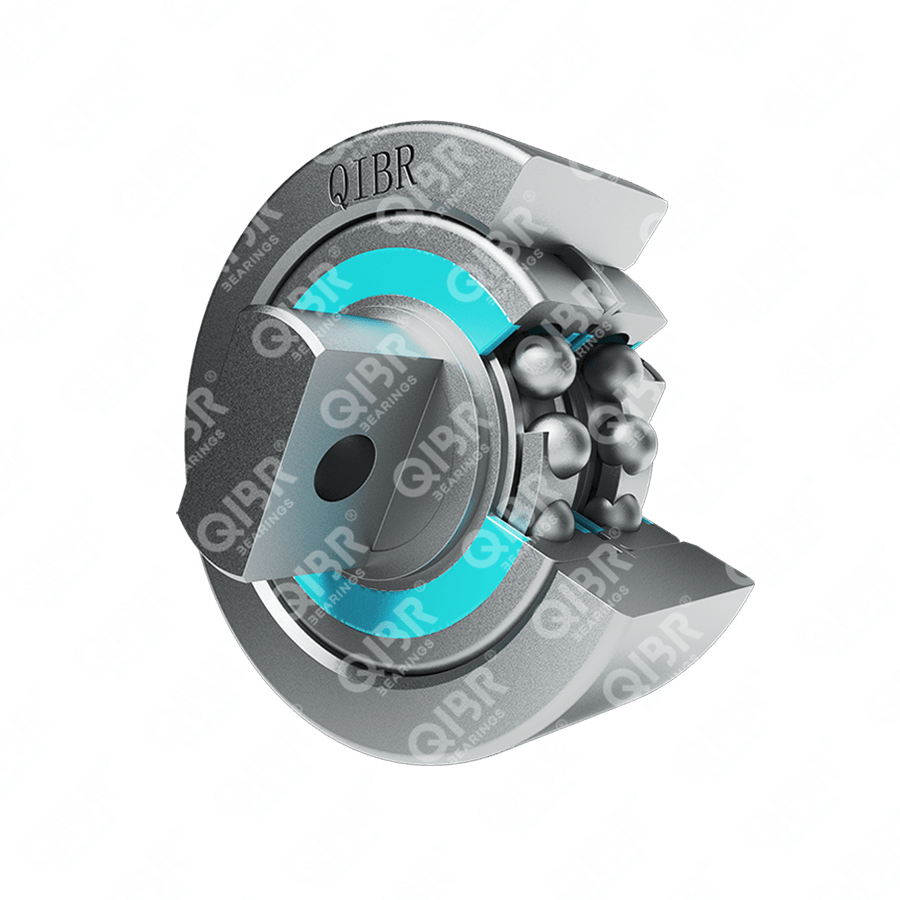

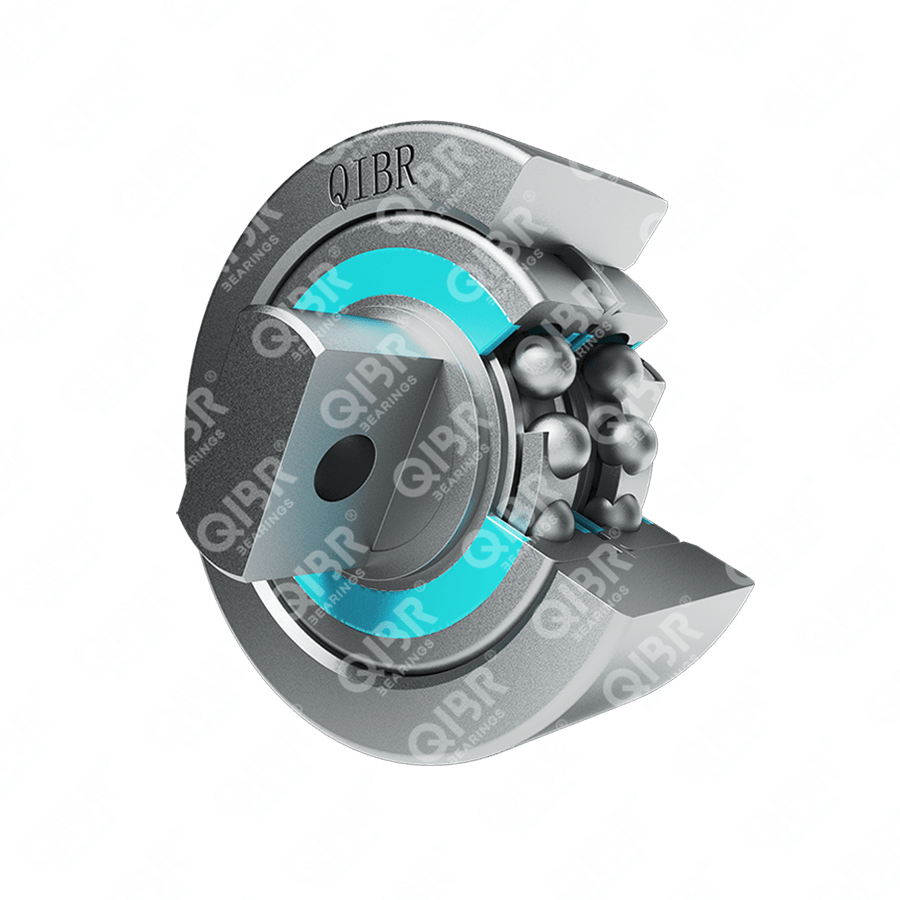

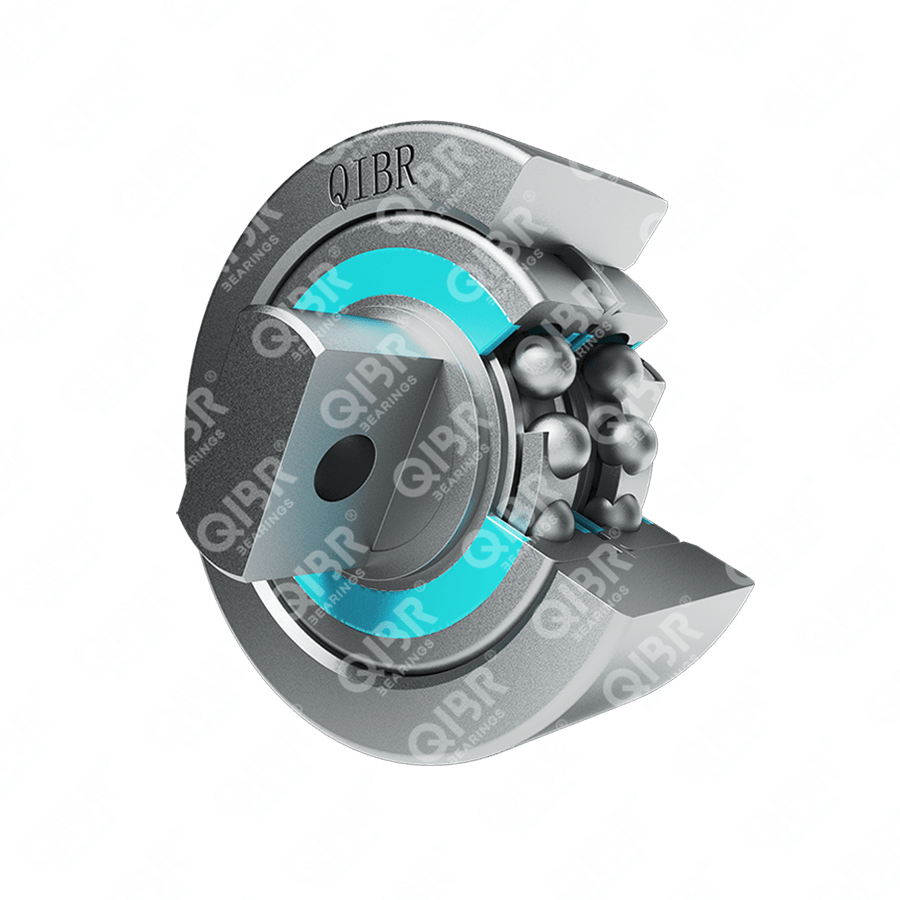

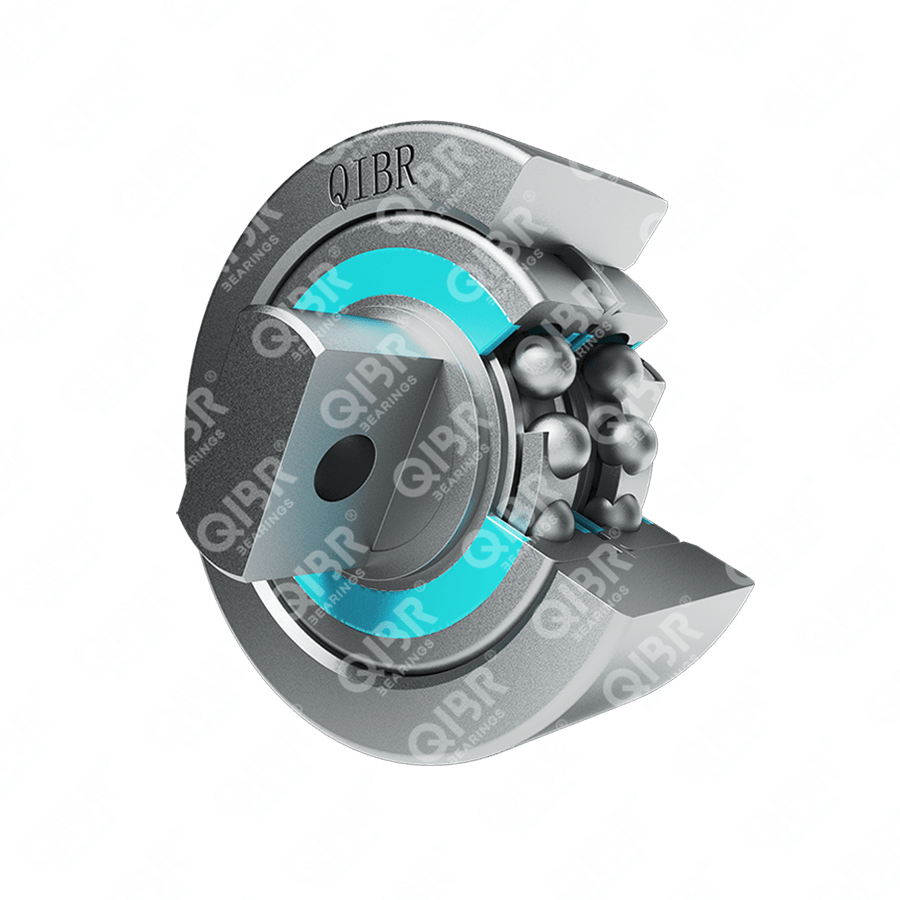

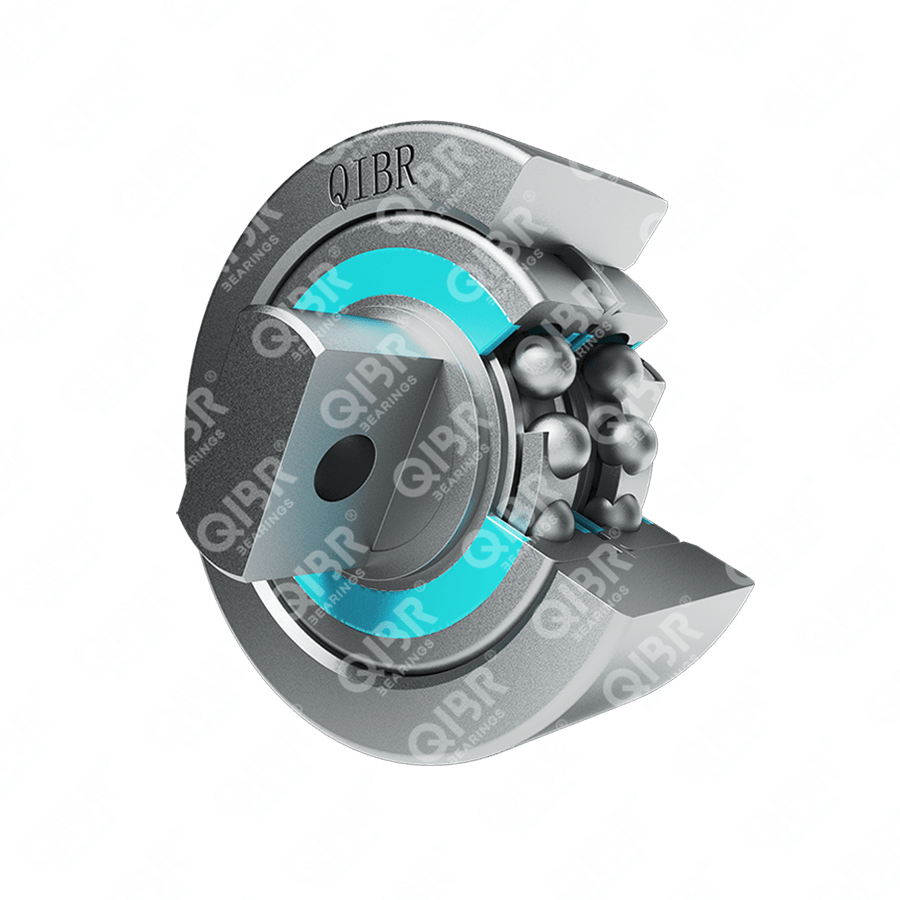

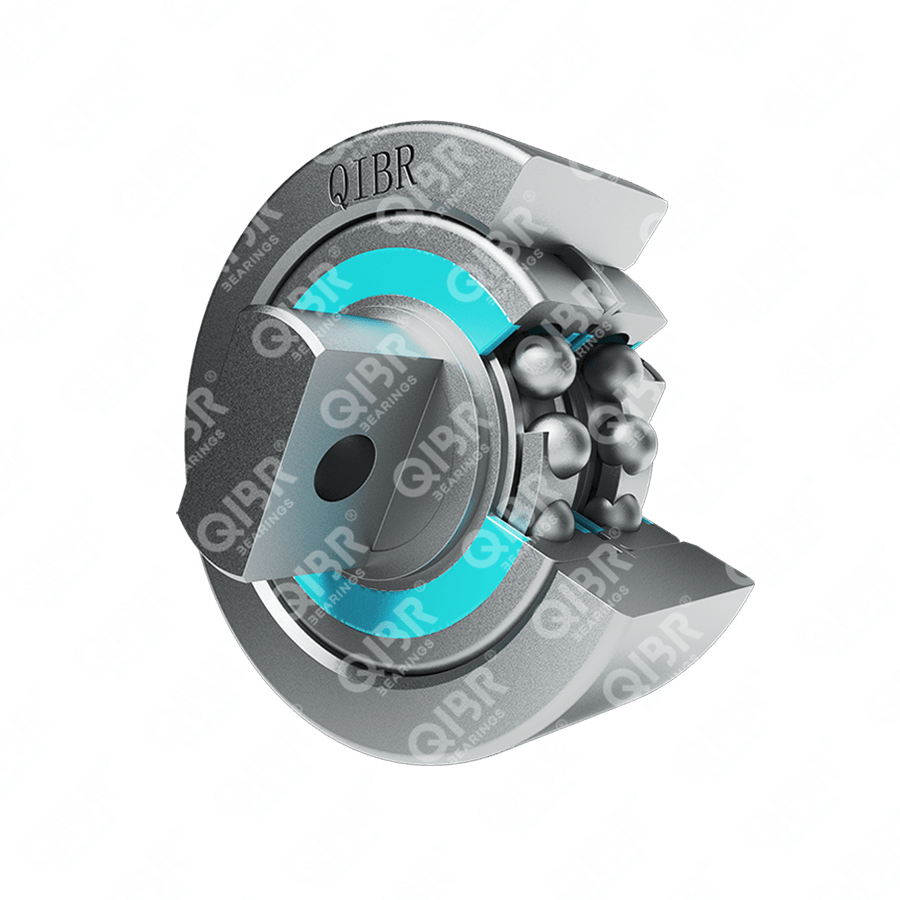

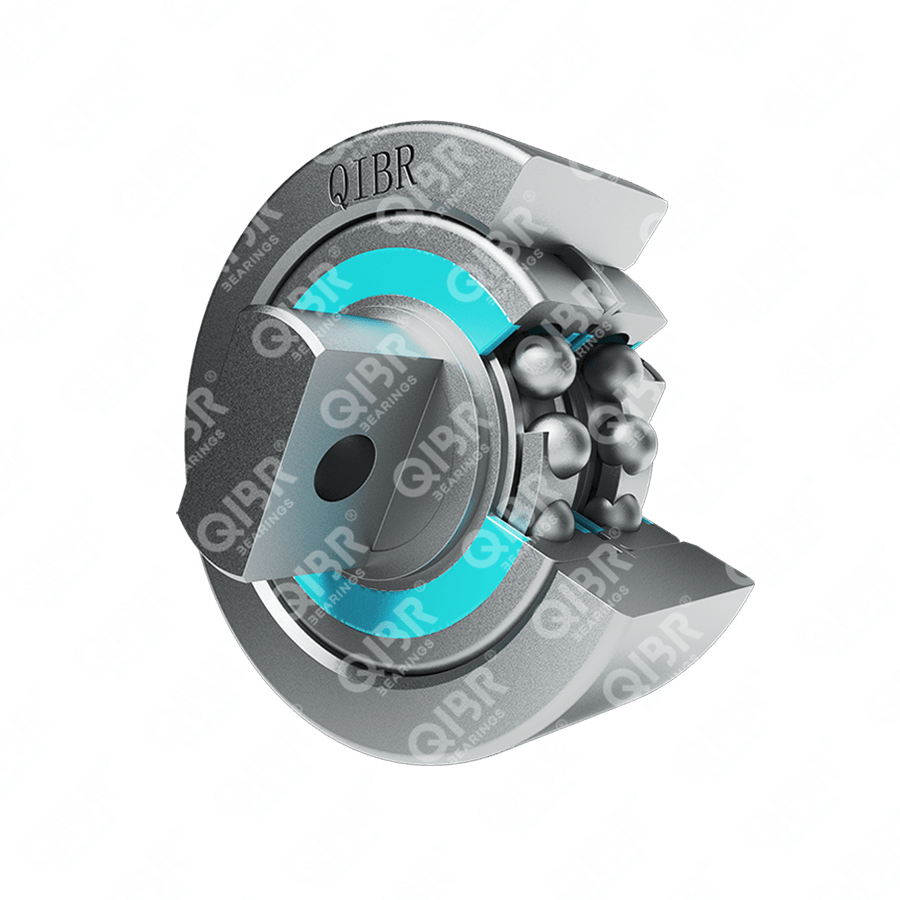

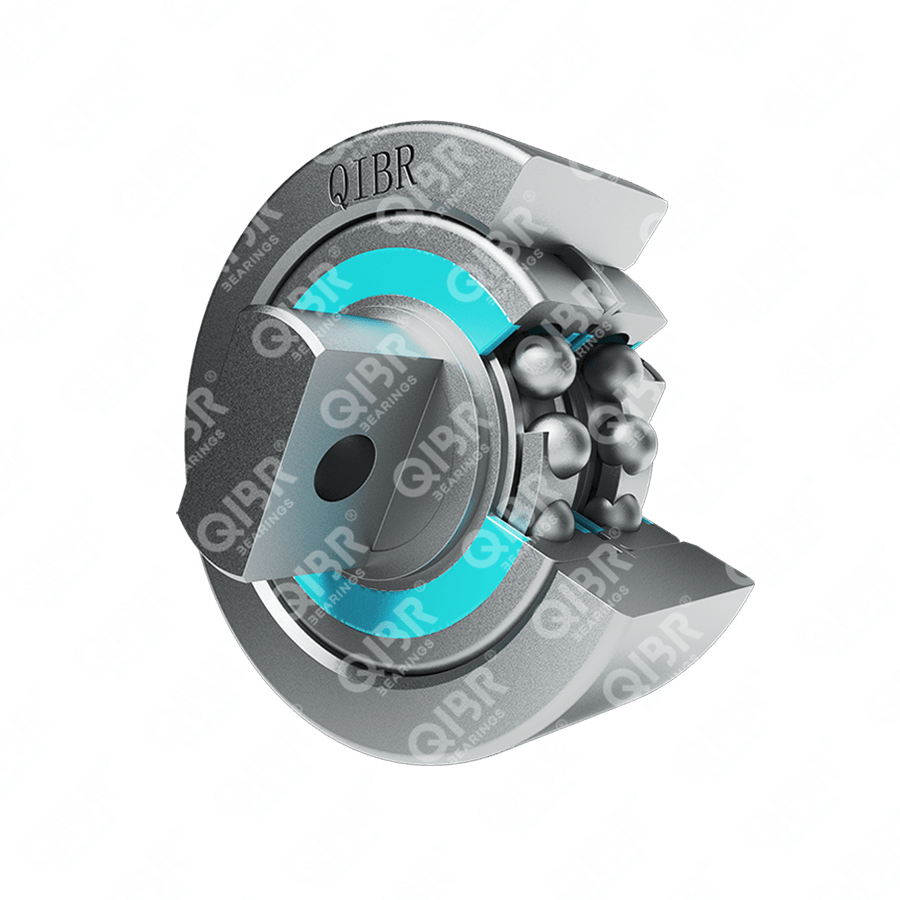

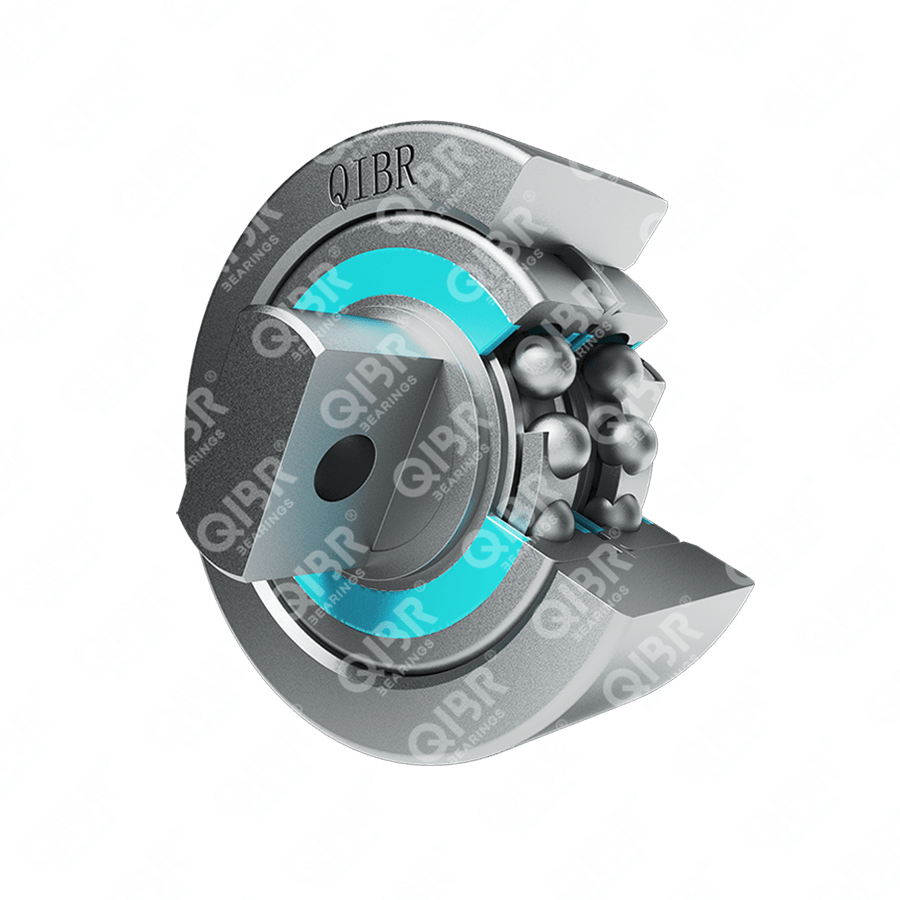

Image may differ from product. See technical specification for details.

Search for the bearing model you need

| NO. | Product | Product Number | Hole distance (B) | Inner ring width (L) | Outer diameter (D) | Outer ring width (C) | Shaft diameter |

|---|---|---|---|---|---|---|---|

| 1 |

|

SR48E58-1 | 48 mm | 65 mm | 58 mm | 22 mm | 19.5 mm |

| 2 |

|

SR48E65-1 | 48 mm | 65 mm | 65 mm | 22 mm | 19.5 mm |

| 3 |

|

SR50E62-1M45 | 50 mm | 64 mm | 62 mm | 30 mm | 28 mm |

| 4 |

|

SR55E62-1M45 | 55 mm | 69 mm | 62 mm | 30 mm | 28 mm |

| 5 |

|

SR60E42-1 | 60 mm | 80 mm | 42 mm | 36 mm | 20 mm |

| 6 |

|

SR60E58-1M2 | 60 mm | 80 mm | 58 mm | 30 mm | 20 mm |

| 7 |

|

SR60E58-2M2 | 60 mm | 80 mm | 58 mm | 30 mm | 20 mm |

| 8 |

|

SR60E58-3M2 | 60 mm | 80 mm | 58 mm | 30 mm | 20 mm |

| 9 |

|

SR60E68-1M45 | 60 mm | 80 mm | 68 mm | 30 mm | 20 mm |

| 10 |

|

SR60E90-1M1 | 60 mm | 80.5 mm | 90 mm | 30 mm | 50 mm |

| 11 |

|

SR70E82-1M2 | 70 mm | 90 mm | 82 mm | 34.5 mm | 30 mm |

| 12 |

|

SR70E82-2M2 | 70 mm | 90 mm | 82 mm | 36 mm | 30 mm |

Features and advantages of forklift side roller bearings with shell

Forklift side roller bearings with shell solve several key problems across various fields, mainly reflected in the following aspects:

1. Reducing friction and wear

The role of forklift side roller bearings with shell is to support the mast, allowing it to move smoothly during lifting and lowering. By contacting the mast and track, they reduce friction, effectively reducing wear and extending the lifespan of the mast and other components.

2. Extra support

The shell provides additional support and protection to the roller, ensuring the roller remains stable under heavy loads. The shell prevents deformation or damage to the roller during loading.

3. Improved load-bearing capacity

Forklift side roller bearings with shell help distribute the weight of the mast evenly, allowing the mast to bear a larger load, thus improving the overall load capacity of the forklift.

4. Enhanced operational stability

Forklift side roller bearings with shell reduce the tilt or deformation of the mast, making lifting and lowering operations more stable, which helps improve work efficiency and operational precision.

Performance improvement and solutions for forklift side roller bearings with shell

1. High-strength alloy materials

Choosing high-strength, wear-resistant alloy materials for the rollers and brackets can significantly improve their compressive and friction resistance, extending service life and adapting to higher loads and frequent operation environments.

2. Raceway optimization

Optimizing the geometry of the inner and outer ring raceways, such as increasing the precision of the raceway and improving surface finish, reduces friction and energy loss, thus enhancing the bearing’s operational efficiency.

3. Strengthened sealing structure

Designing an efficient sealing system to prevent external contaminants such as dust, dirt, and moisture from entering the bearing. A good sealing design helps keep the bearing clean and extends its lifespan.

4. Corrosion-resistant design

For demanding work environments (such as marine or chemical environments), stainless steel, corrosion-resistant coatings, or surface treatment techniques can be used to improve the bearing’s corrosion resistance.

Main application fields of forklift side roller bearings with shell

1. High-rise warehouses

In high-rise warehouse environments, forklifts need to operate in narrow aisles. Forklift side roller bearings with shell help maintain stability during mast lifting, preventing side-to-side wobble and ensuring precise operation when working at heights.

2. Stacking operations

When forklifts need to stack goods at different heights, especially when precise control of the load position is required, forklift side roller bearings with shell provide the necessary support, preventing tilting or collisions during lifting and lowering.

3. Long-distance transport

During long-distance transportation, forklift side roller bearings with shell help reduce the lateral displacement of the forklift mast, decreasing friction and wear, and ultimately extending the forklift’s service life.

4. Narrow aisle operations

For forklifts working in confined spaces, forklift side roller bearings with shell help maintain the balance and stability of the mast, particularly when handling lifting and lowering operations, reducing lateral forces, and ensuring safety during operations.