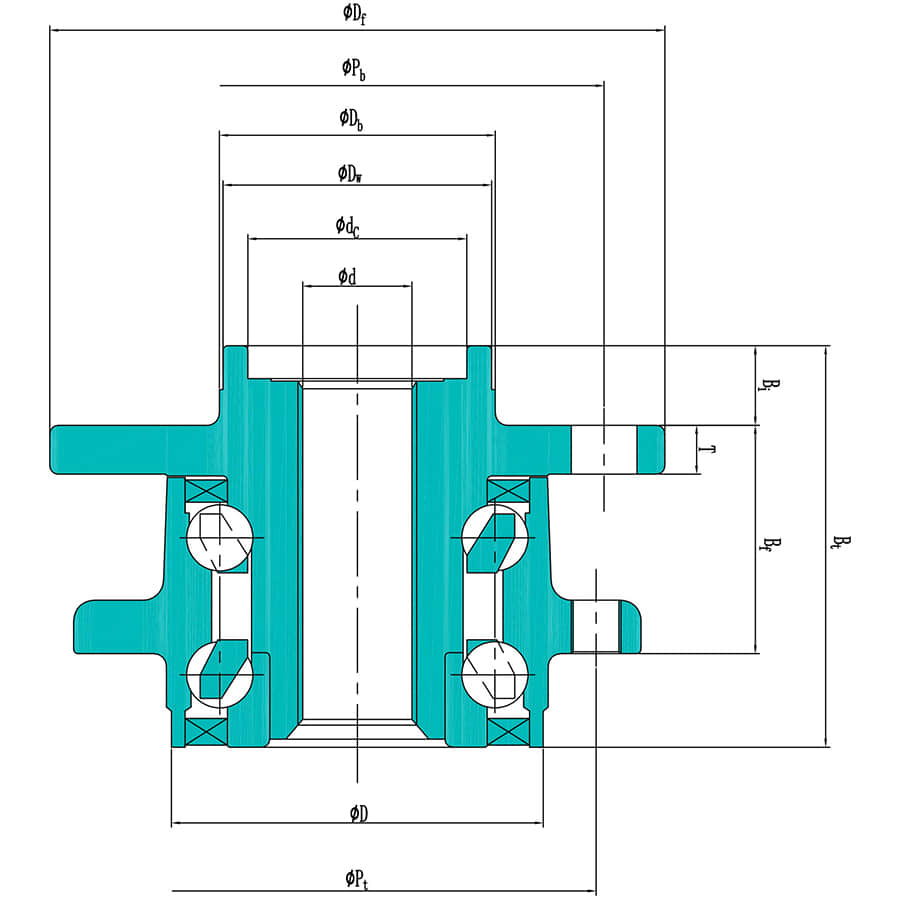

ZA-55BWKH12U-Y-5CP01

- Inner diameter:

- 25.0 mm

- Outer diameter:

- 124.0 mm

- Width:

- 95.3 mm

- Mass:

- 3.370 Kg

We will provide you with the most suitable solution.

Image may differ from product. See technical specification for details.

Specifications

Seris - ZA-55BWKH12U-Y-5CP01

Description

QIBR - ZA-55BWKH12U-Y-5CP01 Hub Bearing Advantages and Applications

ZA-55BWKH12U-Y-5CP01 Hub Bearing, high load capacity, low friction, Inner diameter (d) is 25 mm, Outer diameter (Df) is 124 mm, Width (Bt) is 95.3 mm, Mass is 3.37 kg, suitable for heavy trucks, electric vehicles and new energy vehicles, etc., and is the most widely used bearing in working conditions with high load capacity requirements.

QIBR - ZA-55BWKH12U-Y-5CP01 Hub Bearing Characteristics

ZA-55BWKH12U-Y-5CP01 Hub Bearing, long life, high cost performance. ZA-55BWKH12U-Y-5CP01 Hub Bearing, can bear radial load and certain axial load at the same time, suitable for mechanical equipment with high durability requirements.

ZA-55BWKH12U-Y-5CP01 Hub Bearings Features and Advantages

High load capacity: Capable of withstanding significant radial and axial loads, accommodating the needs of various vehicles.

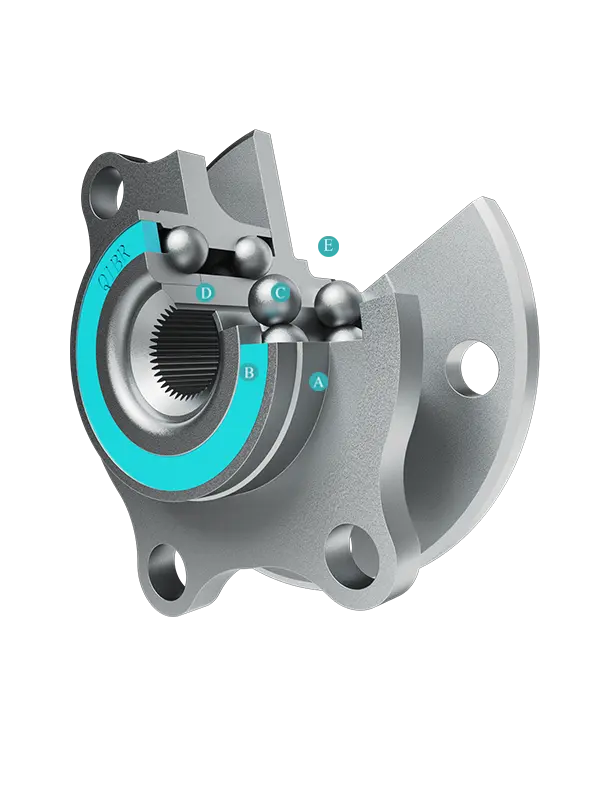

Integrated Design: Combines multiple components into a single unit, simplifying the installation process and reducing the number of parts.

Stability: Provides better wheel stability and handling, reducing vehicle shake and drift during operation.

Strong Adaptability: Exhibits good wear resistance and corrosion resistance, ensuring stable performance even in harsh environments.

Application: Widely used in passenger cars, commercial vehicles, power systems, drive systems, and hubs.

QIBR - ZA-55BWKH12U-Y-5CP01 Hub Bearing Optimization

Seal Materials: Sealing structures can be selected based on the working environment of the bearings, such as 304 stainless steel (corrosion-resistant), hydrogenated nitrile rubber seals (low-temperature resistant), nylon (good elasticity), etc.

High-Performance Materials: The inner and outer flanges can be made of spring steel 65Mn or 55# based on customer requirements.

Grease Selection: Lubricants can be chosen according to customer needs and bearing operating conditions, such as Shell ET2/RN8, Mobilgrease XHP 222, Kunlun HP-R, etc.

More customization: QIBR can design and optimize the bearing according to customer requirements for drawings and bearing working conditions.

QIBR - ZA-55BWKH12U-Y-5CP01 Hub bearing quality control

Dimension measurement: Various high-precision instruments are used to measure multiple dimensions of the bearings, achieving a maximum precision of 0.001mm.

Rotation accuracy: Small surface defects or deviations are measured with a micrometer, with a measurement precision of up to 0.001mm.

Hardness measurement: Use a hardness tester to measure the surface hardness of the bearing, with a measurement accuracy of up to ±0.5HRC.

Metallographic analysis: Use a professional metallographic microscope to analyze the internal metallographic structure of the metal.

Clearance Measurement: Axial clearance of the bearing is measured using a specialized hub axial clearance measuring instrument.

Noise monitoring: Vibration during operation is monitored with a vibration meter, yielding noise data below 60dB.

Sampling Inspection: A sample size of no less than 1% is taken based on the batch of bearings, with an acceptable defect rate of less than 2%.

Raw material control: Steel and parts are purchased from suppliers certified by ISO 14001 to ensure product stability and promote sustainable development.

Features & Benefits

The primary purpose of the hub bearing is to bear weight and provide precise guidance for the rotation of the hub.

Downloads