RUS 38134 KS

- Inner diameter:

- 52 mm

- Outer diameter:

- 133 mm

- Width:

- 38 mm

- Mass:

- 1.53 Kg

We will provide you with the most suitable solution.

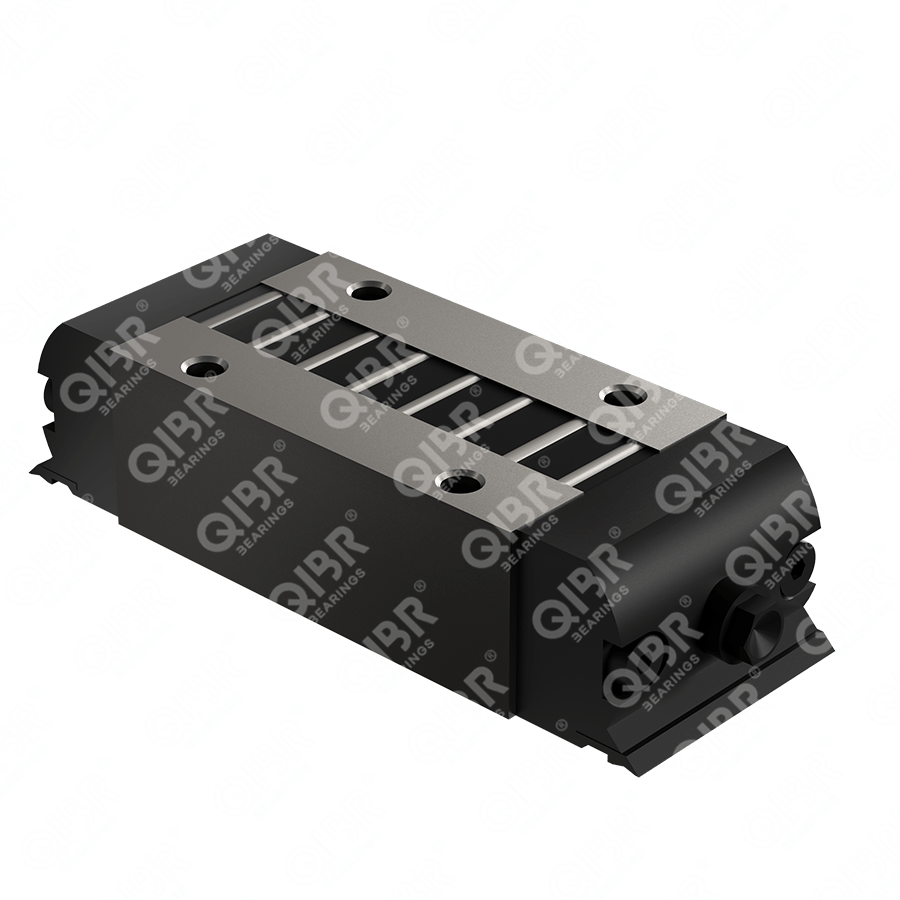

Image may differ from product. See technical specification for details.

Specifications

Seris - RUS 38134 KS

Description

QIBR - RUS 38134 KS Linear Roller Bearings Advantages and Applications

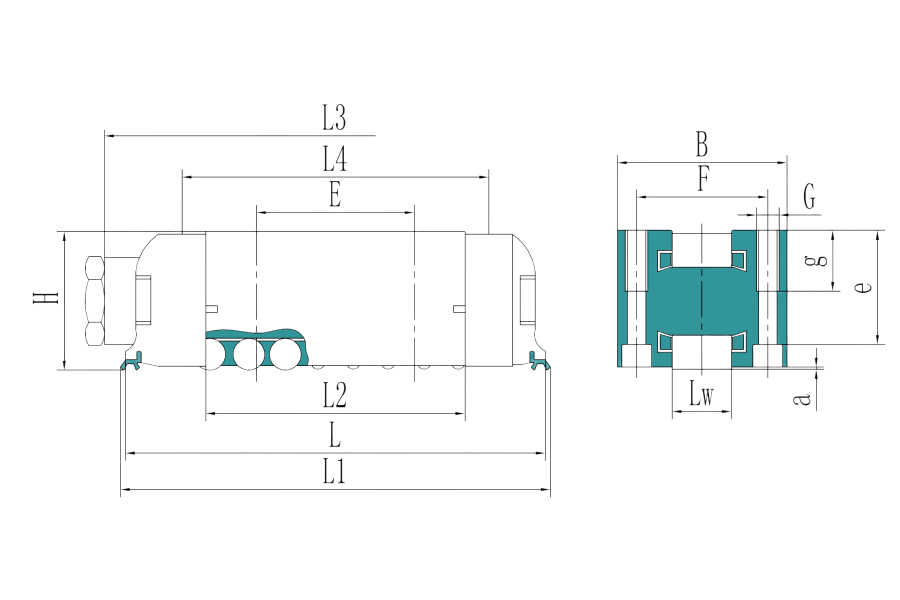

RUS 38134 KS Linear Roller Bearings, high load capacity, long stroke, Height (H) is 38 mm, Width (B) is 52 mm, Mass is 1.53 kg, suitable for printing machines, industrial robots and automobile production lines, etc., and is the most widely used bearing in working conditions with high load capacity requirements.

QIBR - RUS 38134 KS Linear Roller Bearings Characteristics

RUS 38134 KS Linear Roller Bearings, easy to install and maintain, strong adaptability, economical. RUS 38134 KS Linear Roller Bearings, can simultaneously bear radial load, axial load and a certain overturning moment, suitable for mechanical equipment with high travel requirements.

RUS 38134 KS Linear Roller Bearings Features and Advantages

High Precision: Provides high-precision linear motion, suitable for applications requiring high accuracy.

High Load Capacity: The large contact area between the rollers and raceways offers a high load capacity, making it suitable for heavy-duty applications.

Low friction: The low coefficient of friction allows for smooth motion, reducing energy loss.

Vibration Damping: Effectively absorbs shocks and vibrations, protecting machinery and extending service life.

Application: Widely used in fields such as electronic equipment, food machinery, packaging machinery, medical machinery, printing machinery, textile machinery, CNC machine tools, automotive, and digital three-coordinate measuring equipment.

QIBR - RUS 38134 KS Linear Roller Bearings Optimization

High-performance materials: Materials such as high-purity bearing steel, ceramics, stainless steel, etc., can be selected according to customer needs.

Seal Material: Different seal materials, such as rubber, plastic, polyurethane, stainless steel, etc., can be chosen based on customer requirements.

Coatings: Optimize the surface of the guide rail. According to customer needs, use surface treatment technologies such as nitriding, chrome plating or coating to enhance the wear resistance and corrosion resistance of the guide rail.

Lubricants: Suitable lubricants, such as Mobil 1 Synthetic Grease, Klüberplex BEM 41-132, Chevron Texaco Starplex, etc., can be selected based on the operating conditions and different parts of the bearing.

More customization: QIBR can design and optimize bearings according to customer needs and operating conditions.

QIBR - RUS 38134 KS Linear Roller Bearings Quality Control

Dimension measurement: Various professional high-precision instruments are used to measure multiple dimensions of the bearing, with the highest precision reaching 0.001mm.

Hardness measurement: Use a hardness tester to measure the surface hardness of the guide rail, with a measurement accuracy of ±0.5HRC.

Metallographic Analysis: The internal metallographic structure of the metal is analyzed using a professional metallographic microscope.

Noise Monitoring: Vibration data is obtained by monitoring the vibrations during operation with a vibration meter.

Geometric tolerance: Use a profiler to measure the geometry and relative position of the guide rail.

Raw material control: Procurement of steel and parts from ISO 14001 certified suppliers ensures product stability while promoting sustainable development.

Features & Benefits

Linear roller bearings have the advantages of high precision, low friction, high rigidity and long life. They can operate smoothly at heavy loads and high speeds and are suitable for high-precision machine tools and automation equipment. The structural design of linear roller bearings enables them to withstand large radial and axial loads while maintaining high precision movement.

Downloads