QIBR deep groove ball bearings are used in wind turbines

- Industry

- wind turbines

- Location

- China

- Goals

- Maximize the adaptability of bearings in harsh environments

Products used

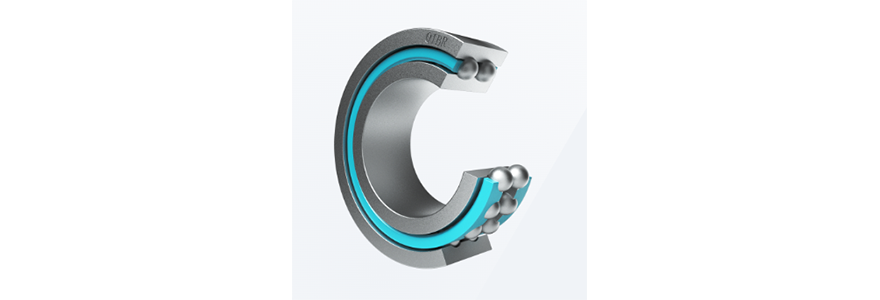

QIBR deep groove ball bearings are used in wind turbines

- Maximize the adaptability of bearings in harsh environments

Customer introduction:

The client is a well-known domestic clean energy R&D and production company, committed to promoting the automotive industry to be more environmentally friendly and efficient. The company has a strong technical foundation and rich market experience in the field of wind turbine power generation, and its products are in the leading position in the industry in terms of driving range, power performance, environmental protection standards, etc. As market competition intensifies, customers' performance requirements for new energy vehicle turbochargers continue to increase in order to further improve vehicle performance and driving experience.

a) Challenges(Problems that exist and why they are not solved)

Wind turbines are a major way to generate electricity with renewable energy. Deep groove ball bearings are generally used in the bearings inside the generators. Due to the harsh operating environment, the constant change of operating loads, long-term unattended operation, lubrication and sealing problems, large size and high-speed operation, etc., the quality of the bearings determines the life of the wind turbines. How to adapt to these problems and ensure the normal operation of wind turbines is a challenge for bearings.

b) Solution (How QIBR Solves the Problem)

QIBR addresses the aforementioned challenges by employing advanced angular contact ceramic ball bearing technology, providing a comprehensive solution:

QIBR technicians conducted 3D modeling of deep groove ball bearings. The parameters of deep groove ball bearings are: inner diameter: 600mm; outer diameter: 1300mm; width: 310mm; pitch circle diameter: 950mm; inner ring groove curvature radius: 113.5mm; outer groove curvature radius: 113.5mm; steel ball diameter: 220mm; number of steel balls: 36; elastic modulus: 2.07e+11Pa; Poisson's ratio: 0.3; density: 7.8kg/m3:; bearing internal clearance: 0.5mm; ring cage clearance: 5.5mm; steel ball pocket clearance: 10mm. Using ABAQUS finite element analysis software and applying constraints, the force conditions when the roller contacts the inner and outer rings, the bearing displacement deformation conditions and the bearing stress distribution diagram were obtained. After several simulations, QIBR technicians obtained the optimal bearing data.

We select high-quality bearing steel and produce the bearings through processes such as heating forging, cooling annealing, and lathe processing. After actual testing, the data is consistent with the software test data.

c) Results

- Optimized the bearing performance and life of wind turbines.

- Improved the stability and efficiency of equipment operation.

- Reduced the damage rate of equipment due to bearing problems.

- Improved the adaptability of bearings in harsh environments.

Testimonials

QIBR's technical experts have provided us with effective solutions to wind turbine bearing problems. In view of the harsh operating conditions of wind turbines, when the wind turbine is working, the operating load of the wind turbine also changes due to changes in wind power. Issues such as the need for ultra-long life were analyzed and optimized one by one, and we continued to communicate with our company's technical staff to develop QIBR deep groove ball bearings to replace traditional bearings. After our company's technical staff conducted tests, the stability and lifespan were improved, and the investment The effect is remarkable after use.

The first cooperation between our company and QIBR has achieved very good results. The CEO spoke highly of QIBR's products and services. We will continue to choose QIBR's professional products.

The first cooperation between our company and QIBR has achieved very good results. The CEO spoke highly of QIBR's products and services. We will continue to choose QIBR's professional products.