Newsroom

Cam and Follower Mechanisms: Innovation and Excellence with QIBR Company

Cam and Follower Mechanisms: Innovation and Excellence with QIBR Company

The cam and follower mechanism is a cornerstone of modern mechanical systems, enabling precise motion control in applications ranging from automotive engines to automated manufacturing equipment. At the heart of this technology lies the interplay between the cam—a rotating or sliding component with a specially designed profile—and the follower, which translates the cam’s contour into controlled linear or oscillatory motion. While the fundamental principles of cam and follower systems are well-established, advancements in materials, design, and manufacturing have elevated their performance to new heights. Among industry leaders, QIBR Company stands out for its innovative approach and commitment to excellence in cam and follower solutions. This article explores the technical advantages of QIBR’s products, emphasizing their reliability, versatility, and engineering precision.

1. Superior Material and Manufacturing Expertise

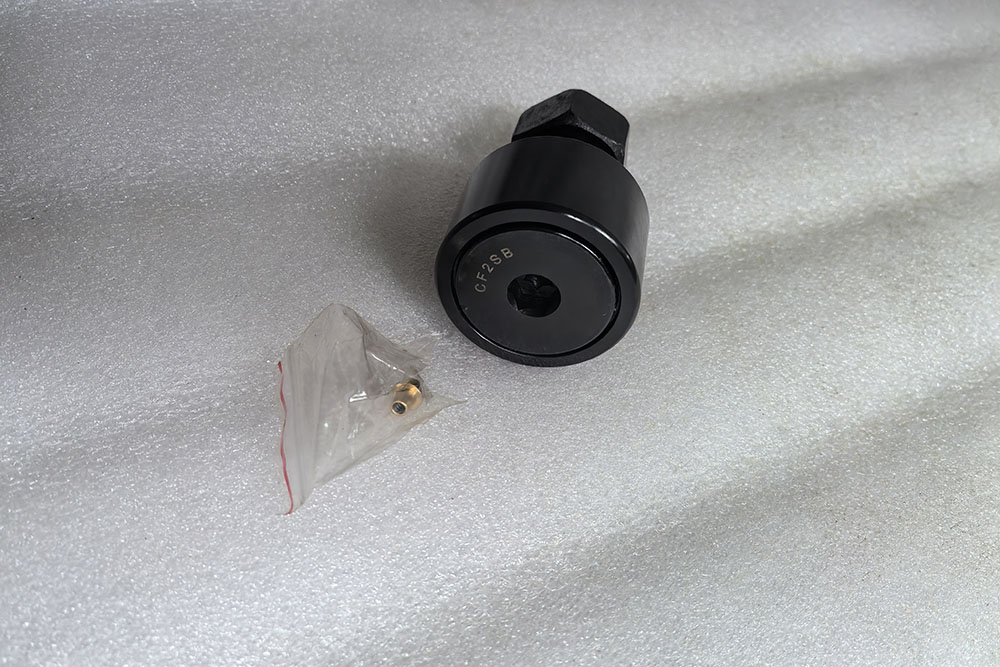

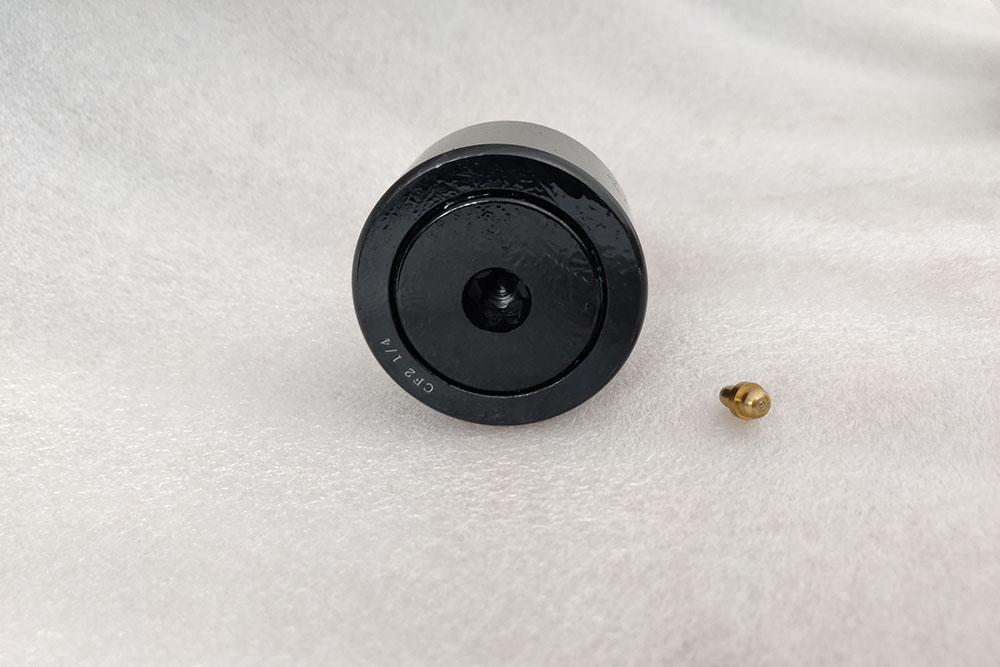

QIBR’s cam and follower systems are engineered using high-grade materials such as hardened steel, ceramic composites, and corrosion-resistant alloys, ensuring durability even in high-stress environments. Leveraging advanced heat-treatment processes and precision grinding techniques, QIBR achieves exceptional surface hardness and wear resistance, critical for applications like automotive camshafts and industrial machinery where components face continuous cyclic loads.

The company’s proprietary manufacturing protocols align with international standards (e.g., ISO and ANSI), guaranteeing dimensional accuracy and consistency. For instance, QIBR’s needle roller bearings, a key component in cam follower assemblies, are designed to minimize friction while maximizing load capacity—a feature highlighted in industrial case studies involving heavy-duty conveyor systems and robotics.

2. Versatile Design for Diverse Applications

QIBR offers a comprehensive portfolio of cam and follower configurations, addressing the unique needs of various industries:

- Plate Cams with Flat-Faced Followers: Ideal for high-speed applications due to low inertia and smooth motion transitions. These systems avoid rigid (rigid impulse) by optimizing acceleration profiles, as demonstrated in textile machinery and packaging automation.

- Roller Followers with Grooved Cams: Engineered for heavy-load scenarios such as metallurgical equipment, these designs reduce contact stress through roller bearings, enhancing longevity.

- Custom Cylindrical and End Cams: Tailored for aerospace and precision instrumentation, where space constraints and motion accuracy are paramount.

QIBR’s ability to integrate form closure and force closure mechanisms ensures reliable contact between cam and follower, even under variable operational conditions.

3. Enhanced Performance Through Advanced Kinematics

QIBR’s engineering team prioritizes motion law optimization to eliminate undesirable dynamics such as vibration or (impulse). By employing sinusoidal and polynomial motion laws, their systems achieve:

- Smooth Acceleration Curves: Critical for high-speed applications like printing presses, where abrupt motion changes can degrade print quality.

- Zero Backlash: Achieved through precision-machined profiles and anti-wear coatings, ensuring repeatability in CNC machining centers.

A case study involving QIBR’s cam-driven robotic arm showcased a 30% reduction in cycle time compared to conventional systems, attributed to optimized follower displacement curves and reduced friction.

4. Customization and Scalability

QIBR distinguishes itself through its agile customization capabilities. Clients can specify parameters such as base circle radius, pressure angle, and follower type (e.g., knife-edge, roller, or flat-faced), with rapid prototyping supported by CAD/CAM simulations. For example, a partnership with a European automotive manufacturer led to the development of a compact cam mechanism for valve timing, reducing engine weight by 15% while maintaining torque efficiency.

Additionally, QIBR’s modular designs allow seamless integration with existing systems, from agricultural machinery to renewable energy installations like wind turbine pitch control mechanisms.

5. Commitment to Sustainability and Support

QIBR’s eco-conscious manufacturing processes minimize waste and energy consumption, aligning with global sustainability goals. Their cam followers are also designed for easy maintenance, with replaceable rollers and lubricant-free options for harsh environments.

The company’s technical support network provides 24/7 consultation, addressing challenges such as cam profile distortion or follower misalignment. Training programs on “reverse design methodology” further empower clients to troubleshoot and optimize their systems.

Conclusion

In an era where precision and reliability define industrial success, QIBR Company emerges as a leader in cam and follower technology. By combining cutting-edge materials, versatile design, and motion optimization, QIBR delivers solutions that exceed performance benchmarks across sectors. Whether enhancing the efficiency of a production line or enabling breakthroughs in automation, QIBR’s commitment to innovation ensures that their cam and follower systems remain at the forefront of mechanical engineering excellence.

For engineers and industry stakeholders seeking to elevate their systems, QIBR’s blend of technical prowess and customer-centric innovation offers a compelling advantage. Explore their catalog to discover how tailored cam and follower solutions can transform your applications.