Newsroom

Double Row Ball Slewing Bearings: Innovation and Excellence by Luoyang QIBR Bearing Co., Ltd.

Double Row Ball Slewing Bearings: Innovation and Excellence by Luoyang QIBR Bearing Co., Ltd.

Introduction

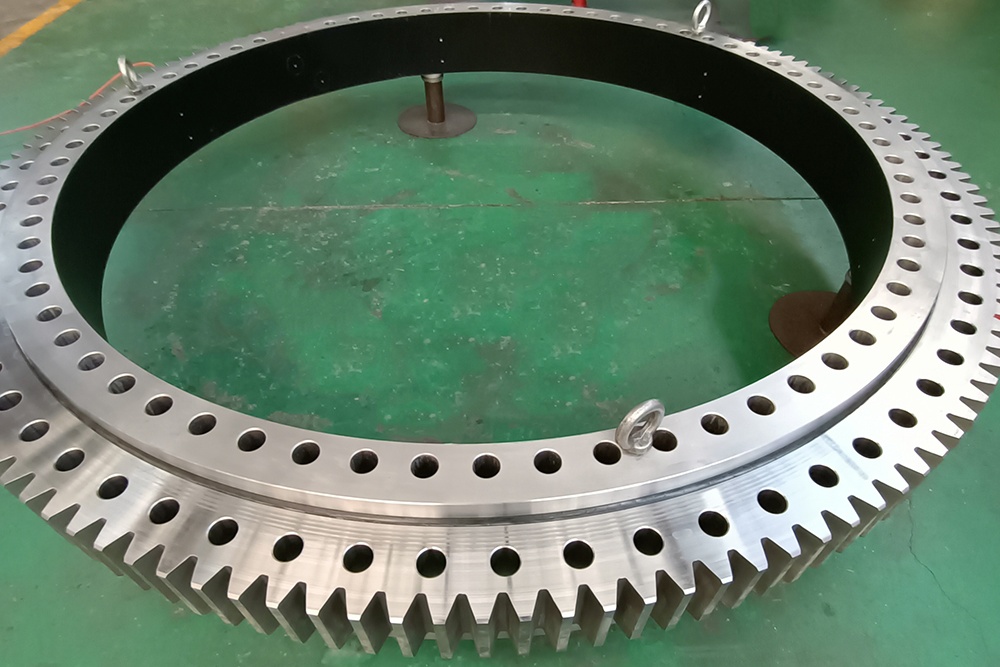

Double row ball slewing bearings are critical components in heavy machinery, enabling rotational movement while supporting axial, radial, and moment loads. These bearings are widely used in industries such as construction, renewable energy, material handling, and aerospace. Luoyang QIBR Bearing Co., Ltd. (QIBR), a leading Chinese manufacturer, has established itself as a pioneer in the design and production of high-performance double row ball slewing bearings. With over two decades of expertise, QIBR combines advanced manufacturing technologies, rigorous quality control, and customer-centric solutions to deliver bearings that meet global standards. This article explores the technical features, manufacturing processes, and industrial applications of QIBR’s double row ball slewing bearings, highlighting the company’s commitment to innovation and reliability.

Technical Features of QIBR’s Double Row Ball Slewing Bearings

Double row ball slewing bearings are characterized by their two rows of rolling elements (steel balls) arranged between inner and outer rings. QIBR’s designs incorporate several advanced features:

1. Robust Load Capacity

QIBR’s bearings are engineered to handle combined axial, radial, and overturning moment loads simultaneously. The double-row configuration distributes stress evenly across the rolling elements, enhancing load-bearing efficiency. For instance, their bearings can support static loads up to 20 metric tons and operate under dynamic conditions in demanding environments.

2. Optimized Structural Design

The bearings feature three seat rings with precisely arranged steel balls and spacers. The upper and lower raceways are designed with 90° contact angles, allowing them to withstand high axial forces and tipping moments. This design is particularly suited for applications like tower cranes and excavators, where radial forces exceed 10% of axial loads.

3. Customization and Versatility

QIBR offers tailored solutions, including variations in gear types (internal, external, or no gear), sealing mechanisms, and lubrication systems. Their bearings are available in outer diameters ranging from 50 mm to 8,000 mm, catering to diverse industrial needs.

4. Material Excellence

Using high-grade steel alloys such as 50Mn and 42CrMo, QIBR ensures superior hardness (55–62 HRC) and wear resistance. Heat treatment processes refine the material’s microstructure, enhancing durability and fatigue resistance.

Manufacturing Excellence at QIBR

QIBR’s production facility in Luoyang, Henan Province, integrates state-of-the-art technology and stringent quality protocols:

1. Precision Machining

The company employs over 200 high-precision machines, including CNC machining centers and surface grinders, to achieve micron-level accuracy in raceway geometry. This precision minimizes friction and ensures smooth rotation.

2. Advanced Heat Treatment

QIBR utilizes controlled heating, holding, and cooling processes to optimize material properties. Their heat treatment equipment enhances hardness and structural integrity, critical for bearings operating under heavy loads.

3. Automated Assembly

Intelligent assembly lines reduce human error and improve consistency. Automated systems align rolling elements and rings with precision, while statistical process control (SPC) monitors quality at every stage.

4. Quality Assurance

QIBR holds certifications such as ISO 9001, ISO 14001, CE, and SGS. Each bearing undergoes rigorous testing, including load capacity assessments, noise level checks, and lifespan simulations.

Industrial Applications

QIBR’s double row ball slewing bearings are integral to numerous sectors:

1. Construction Machinery

Used in tower cranes, excavators, and concrete pumps, these bearings enable 360° rotation under extreme loads. Their robust design ensures reliability in dynamic environments.

2. Renewable Energy

In wind turbines and solar tracking systems, QIBR’s bearings facilitate precise alignment with wind direction or sunlight. Their corrosion-resistant coatings and low-maintenance designs are ideal for harsh outdoor conditions.

3. Material Handling

Port cranes, stacker-reclaimers, and conveyor systems rely on these bearings for smooth operation and high load capacity. Customized gear integrations further enhance performance.

4. Aerospace and Defense

QIBR supplies bearings for radar systems, missile launchers, and surveillance equipment, where precision and reliability are non-negotiable.

QIBR’s Competitive Edge

1. Customer-Centric Approach

QIBR collaborates closely with clients to develop bespoke solutions. Their engineers provide technical support, from design optimization to post-installation maintenance.

2. Global Reach

Serving Fortune 500 companies and international partners, QIBR’s bearings are exported worldwide. Their logistics network ensures timely delivery, with options for FOB, CIF, and DDU terms.

3. Sustainability Initiatives

QIBR prioritizes eco-friendly practices, such as energy-efficient production and recyclable packaging. Their solar-compatible bearings align with global green energy goals.

Conclusion

Luoyang QIBR Bearing Co., Ltd. exemplifies innovation in the slewing bearing industry. Through cutting-edge technology, meticulous craftsmanship, and a focus on sustainability, QIBR delivers double row ball slewing bearings that redefine performance standards. As industries increasingly demand precision and durability, QIBR remains a trusted partner, driving progress in machinery and renewable energy sectors worldwide.