Newsroom

Adjustment Measures for Problems after Bearing Installation

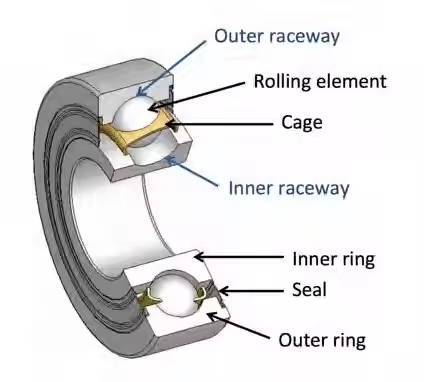

2018-11-25When installing, do not directly hammer the end face and non-loading surfaces of the bearing. Instead, use pressure blocks, sleeves or other installation tools to ensure that the deep groove ball bearing is evenly loaded. Never install the bearing by transmitting force through the rolling elements. If the installation surface is coated with lubricating oil, the installation will be smoother. If the interference fit is relatively large, place the bearing in mineral oil, heat it to 80 - 90 °C, and then install it as soon as possible. Strictly control the oil temperature not to exceed 100 °C to prevent the hardness reduction due to the tempering effect and the impact on dimensional recovery. When encountering difficulties in disassembly, it is recommended that you use a disassembly tool to pull outwards while carefully pouring hot oil onto the inner ring. The heat will cause the inner ring of the deep groove ball bearing to expand, making it easier to remove.

Not all bearings require the minimum working clearance. You must select an appropriate clearance according to the conditions. In the national standard GB/T 4604 - 1993, the radial clearances of rolling bearings are divided into five groups: group -2, group 0, group 3, group 4, and group 5. The clearance values increase in sequence, and group 0 is the standard clearance. The basic radial clearance group is suitable for general operating conditions, normal temperatures, and common interference fits. Bearings working under special conditions such as high temperature, high speed, low noise, and low friction should use a larger radial clearance. For precision spindles and deep groove ball bearings used in machine tool spindles, a smaller radial clearance is more appropriate. For roller bearings, a small amount of working clearance can be maintained. In addition, for separable bearings, there is no concern about clearance. Finally, the working clearance of the bearing after installation is smaller than the original clearance before installation because the bearing has to rotate under a certain load, and there are also elastic deformations caused by bearing fits and loads.

Regarding the sealing defect problems of bearings with insert-type seals, two steps need to be strictly followed during the adjustment process.

1. Change the cover structure of the insert-type sealed bearing to both sides of the deep groove ball bearing. Adjust from the bearing installation structure of the equipment. There is no need to directly contact the bearing. Perform dust prevention treatment on the bearing from the outside. The sealing effect of this structure is better than the self-sealing of the bearings sold by bearing agents. It directly blocks the intrusion path of particulate matter and ensures the cleanliness inside the bearing. This structure also enlarges the heat dissipation space of the bearing and causes less damage to the anti-fatigue performance of the bearing.

2. Although the external sealing method of the deep groove ball bearing has a good sealing effect, it also blocks the heat dissipation path to some extent. Therefore, cooling components need to be installed. The cooling device can reduce the operating temperature of the lubricant. After cooling, natural heat dissipation can avoid the high-temperature operation of the bearing.

For more info about bearing heat treatment, feel free to contact QIBR.