Newsroom

Bearing life analysis report

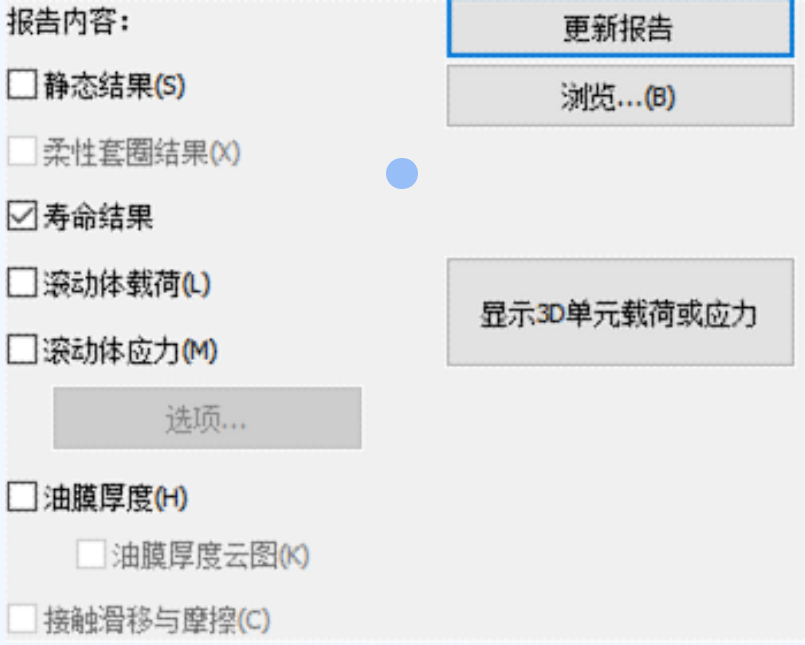

2024-02-15Select Lifetime Results and click Update Report.

1. ISO 281

2. Romax adjusted ISO 281

3. ISO/TS 16281 Basic

4. ISO/TS 16281 Advanced

5. DIN ISO Supplemental

6. Romax adjusted DIN ISO Supplemental

7. Romax Advanced Life

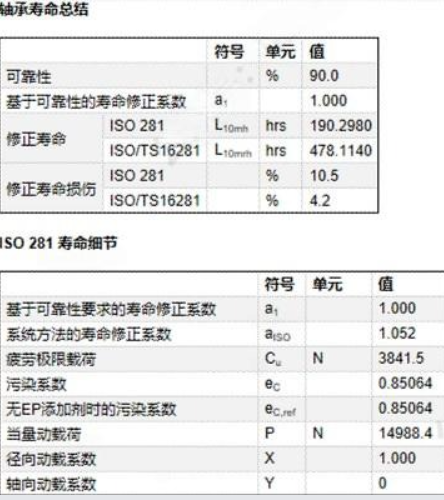

There are two ways to perform TS 16281 standard calculations: basic and advanced.

In the basic calculation method, the kappa value is calculated based on the ratio of the actual viscosity of the lubricant to the required viscosity, and the oil film parameters are not used.

The advanced method uses the oil film thickness to calculate the oil film parameters, and the kappa value is calculated based on this. ISO/TS 16281 and Romax advanced life algorithms require users to have advanced bearing analysis modules.

You can repeat the above operations and analysis for other conditions (such as 80%, 60%, 40%, 20% load conditions) to obtain the corresponding advanced bearing analysis results.

To ensure that the life calculation method you need is selected, you may need to return to the gearbox window and open the Analysis window, click the Setup tab, and select Load Capacity Calculation Bearings sub-tab. In the Setup Analysis window, select ISO/TS 16281 Method in the upper option box if it is not already selected, and select ISO 281 Rev 2 (2007).

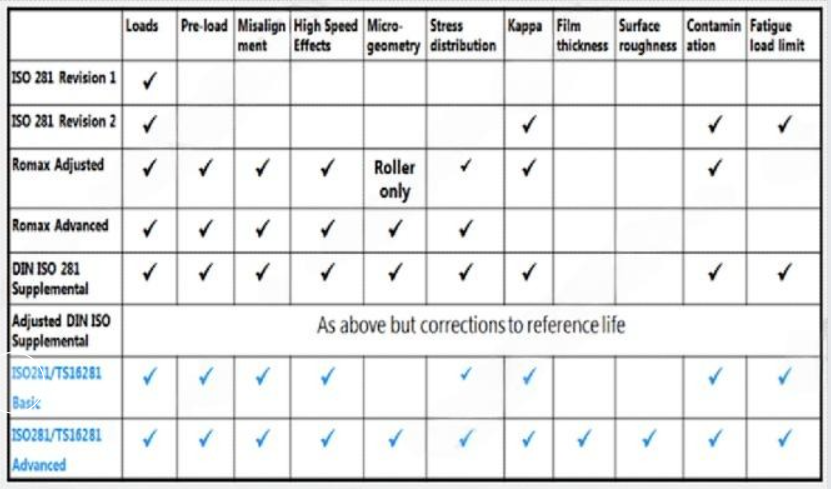

Romax Bearing Life Calculation Methods

Over the years Romax has developed different bearing life calculation methods. The two methods we recommend users use are ISO 281 and ISO 281/TS 16281.

If ISO 281/TS 16281 is selected, the life calculation will use either the Basic or Advanced method. If the Advanced Bearing Details section is set to Estimate, the Basic method will be used. If the user defines the Advanced Bearing Details, this uses the Advanced method. For the purposes of this tutorial we will turn off the Estimate definition feature, but we will not change the values given。

The ISO 281 Rev 2 (2007) standard allows you to calculate the life factor aISO taking into account the influence of lubrication and cleanliness. If you want to get a closer approximation to the actual bearing life, you need to set the lubricant properties. In the Lubricant submenu, define parameters such as viscosity and temperature to complete the calculation. We will explain lubricants in Task 5.