Newsroom

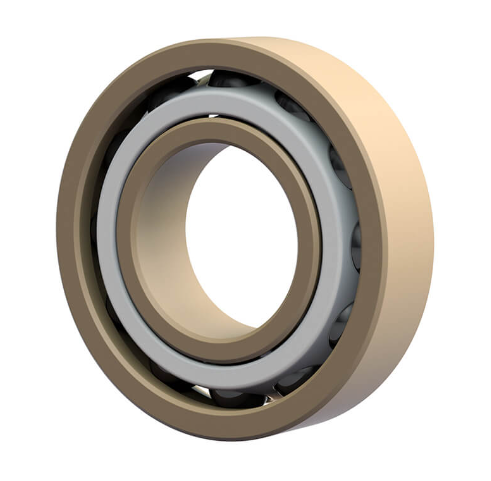

Ceramic angular contact ball bearing

2025-04-15An ceramic angular contact ball bearing is a type of angular contact bearing that uses ceramic balls instead of traditional steel ones. These bearings are designed to handle combined radial and axial loads—particularly where high precision, speed, and reliability are required.

Here’s a breakdown of its features and applications:

1.Key Features:

I.Ceramic Balls (usually Silicon Nitride, Si₃N₄):

- Lighter and harder than steel.

- Non-conductive, suitable for electrical insulation.

- Lower density = less centrifugal force at high speeds.

- Highly resistant to wear, corrosion, and heat.

II.Angular Contact Design:

- Typically has a contact angle (15°, 25°, or 30°), enabling it to handle axial loads in one direction.

- Often used in pairs or sets to accommodate axial loads in both directions or combined loads.

III.High-Speed Capability:

- Low friction + lightweight ceramic balls = excellent for high-speed applications.

IV.Longer Service Life:

- Less heat generation and wear compared to steel bearings.

2.Applications

- Machine tool spindles

- Electric motors (especially high-speed or high-frequency types)

- Aerospace

- Semiconductor manufacturing

- Dental or medical equipment

- Wind turbines

3.Example Designation

7205C-HC-P4-CE Si₃N₄

- 7205C: Angular contact bearing with 25° contact angle

- HC: Hybrid ceramic (ceramic balls + steel rings)

- P4: High precision

- CE: Preload specification

For more information, feel free to contact QIBR