Newsroom

Common installation forms and installation precautions for angular contact bearings

2018-09-05Angular contact ball bearings are typically installed in pairs and require a preload. Proper installation ensures improved operational accuracy and extended bearing lifespan. Improper installation can compromise precision and shorten lifespan.

1. Installation Configurations

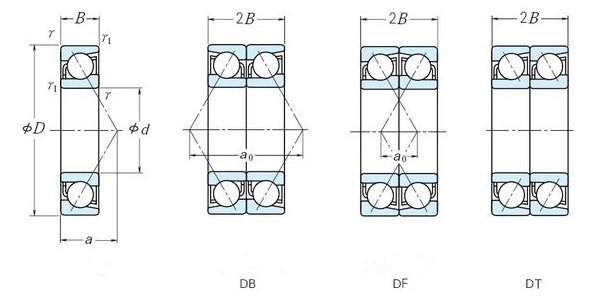

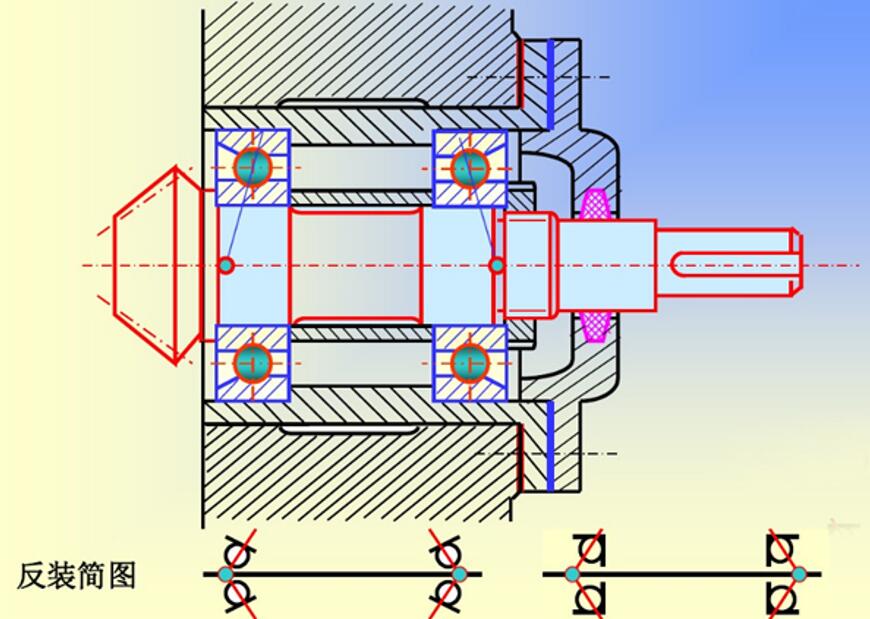

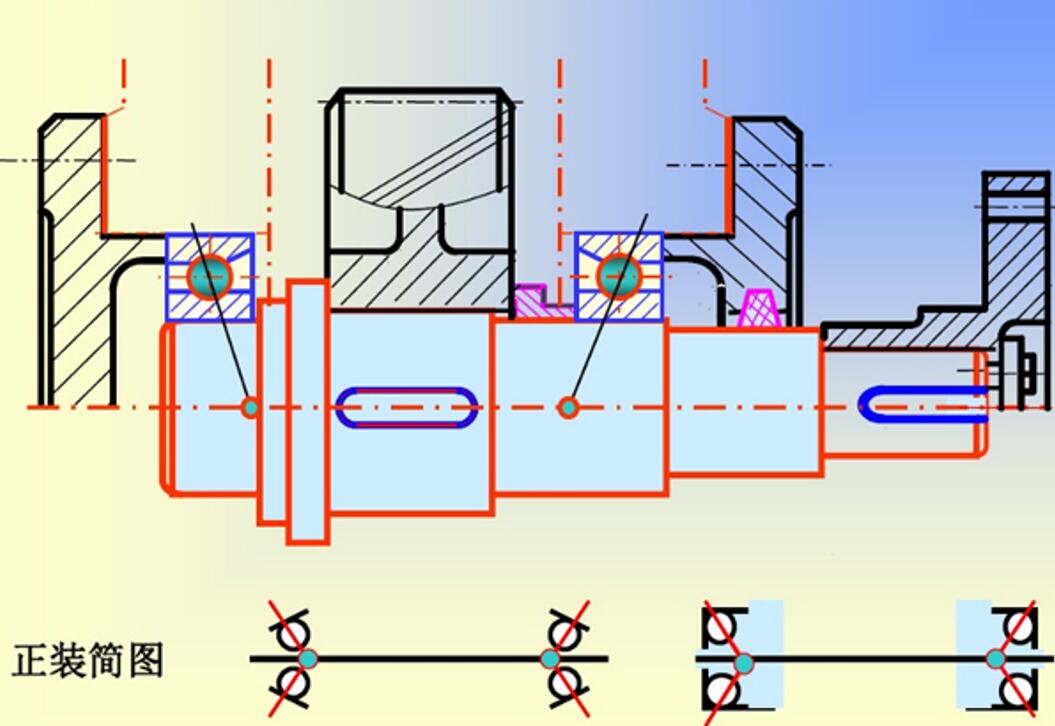

Angular contact ball bearings can be installed in the following configurations: back-to-back, face-to-face, and tandem arrangement.

(1) Back-to-Back Installation (DB Configuration)

Description: The wide ends of the two bearings face each other.

Characteristics: Contact angle lines diverge along the axis of rotation, provides increased radial and axial support rigidity and better resistance to deformation.

Applications: Used where high rigidity and load distribution are crucial.

(2) Face-to-Face Installation (DF Configuration)

Description: The narrow ends of the two bearings face each other.

Characteristics: Contact angle lines converge along the axis of rotation, provides lower support rigidity but can accommodate slight alignment errors. Eliminates the original gap between the outer rings when compressed, increasing preload.

Applications: Suitable for systems where moderate rigidity and alignment flexibility are needed.

(3) Tandem Arrangement (DT Configuration)

Description: Both bearings' wide ends face the same direction, with contact angles parallel.

Characteristics: Allows the bearings to share the same direction of applied load. To ensure axial stability, two pairs of tandem bearings must be installed opposite each other.

Applications: Used for handling high unidirectional axial loads.

2. Preload Calculation and Adjustment

Calculation: Preload is applied by grinding one bearing ring's end face or using spacer rings of different thicknesses between the inner and outer rings to tightly fit the bearings together, ensuring the balls are in close contact with the raceways.

Adjustment: Preload is fine-tuned during a no-load test run. Bearings should undergo a test run at operating speed for at least 2 hours, and the temperature rise should not exceed 15°C.

Installation Precautions

- Installation Environment

Bearings should be installed in a clean, dust-free room.

Bearings must be carefully matched, and spacer rings should be ground to ensure equal height for inner and outer rings. Parallelism should be controlled within 1 μm.

- Cleanliness

Wash the bearings thoroughly before installation.

During washing, place the inner ring slope facing upward. Bearings should rotate smoothly without any resistance.

Bearings must be dried and then lubricated with grease or oil.

For grease lubrication, use high-quality grease with anti-oxidation, anti-rust, and extreme pressure properties. Grease fill should be 30%-60% of the bearing or housing volume.

- Tools

Use specialized tools for installation to ensure even force distribution.

Avoid direct hammering of the bearing. Instead, apply uniform pressure to the ring's end face using a sleeve or hydraulic press.

- Pre-Installation Inspection

Check the fit surfaces, shoulder end faces, grooves, and connecting surfaces for quality.

Clean all mating and connection surfaces, remove burrs, and clean unprocessed cast surfaces of residual sand.

- Storage Environment

Store bearings in a clean, ventilated environment free from corrosive gases.

Relative humidity should not exceed 65%. For long-term storage, apply periodic rust prevention.

- Clearance Adjustment

For single-row tapered roller bearings, adjust clearance during installation based on operating conditions and fit interference.

Double-row tapered roller bearings and water pump bearings typically have pre-adjusted clearance from the factory and require no further adjustment.

- Rotation Test

After installation, conduct a rotation test:

Begin with manual rotation of the shaft or housing to check for abnormalities.

Proceed with no-load, low-speed operation, gradually increasing speed and load while monitoring noise, vibration, and temperature rise.

Stop immediately if abnormalities are detected and inspect the assembly.

Use the angular contact ball bearings only after successful test results.