Newsroom

Effect of High Rotational Speed on Deep Groove Ball Bearings

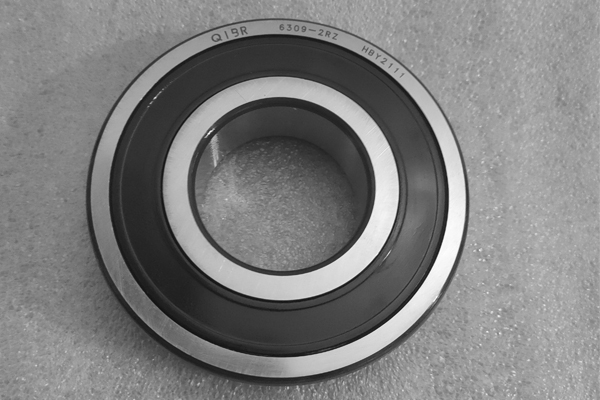

2025-09-19Deep groove ball bearings are widely used in various industrial applications due to their simple structure, low friction, and ability to handle radial and limited axial loads. However, when operating at high rotational speeds, their performance and service life can be significantly affected. Understanding these influences is essential for proper bearing selection, maintenance, and reliable equipment operation.

1.Increased Friction and Heat Generation

As the rotational speed rises, both rolling and sliding friction within the deep groove ball bearings increase. This intensifies the contact stress between rolling elements and raceways, causing heat to accumulate rapidly.

- Consequences: Excessive temperature rise may lead to dimensional changes, loss of internal clearance, reduced hardness of bearing materials, and even thermal seizure in extreme cases.

- Example: In electric motors and high-speed fans, insufficient control of bearing temperature often results in reduced efficiency and unexpected shutdowns.

2. Lubrication Challenges

At high speeds, lubrication conditions become more critical. Grease tends to be thrown out by centrifugal force or loses its effectiveness as the base oil evaporates, leaving behind thickener residues. Oil lubrication may also struggle to maintain a continuous film at extremely high speeds.

- Consequences: Inadequate lubrication leads to metal-to-metal contact, higher vibration, accelerated wear, and risk of premature failure.

- Solutions: Use low-friction, high-speed greases, or implement oil-air or oil-mist lubrication systems to ensure a constant lubricant supply.

3. Centrifugal Force and Mechanical Stress

As the rolling elements spin faster, the centrifugal force acting on them increases exponentially with speed. This not only alters the load distribution inside the bearing but also introduces additional stresses on the cage and raceways.

- Consequences: Cage deformation or fracture, increased internal clearance variation, and reduced rigidity.

- Example: In aerospace or spindle applications, improper handling of centrifugal forces can result in significant performance degradation.

4. Noise, Vibration, and Stability Issues

High-speed bearings are prone to generating elevated noise and vibration due to dynamic instabilities, resonance effects, and irregular lubrication distribution.

- Consequences: Increased vibration can affect machine accuracy, reduce comfort in automotive applications, and accelerate fatigue failure of surrounding components.

- Mitigation: Precision manufacturing, optimized cage design, and the use of ceramic rolling elements can reduce noise and vibration at high speeds.

5. Material and Design Considerations

Not all deep groove ball bearings are suitable for high-speed operation. Standard bearings may fail prematurely, while specially designed high-speed bearings can withstand such demands.

- Key factors

- Use of high-purity, heat-resistant steel or hybrid designs with ceramic balls.

- Optimized internal geometry to reduce frictional torque.

- Special cage materials (e.g., phenolic resin, polyamide) to withstand high centrifugal forces.

6. Conclusion

When selecting and using deep groove ball bearings for high-speed applications, engineers must consider multiple factors: friction, lubrication, centrifugal forces, vibration, and material properties. Proper solutions include choosing bearings specifically designed for high-speed use, employing advanced lubrication techniques, and implementing effective cooling and monitoring systems.

By doing so, equipment can achieve higher efficiency, longer service life, and more stable operation—even under demanding high-speed conditions.