Newsroom

Features and Applications of 9.5mm Steel Balls

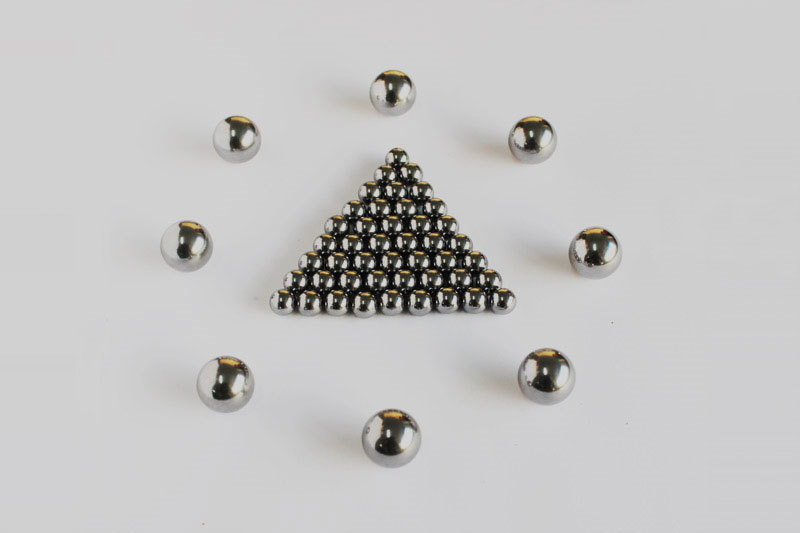

2025-02-14In the fields of mechanical manufacturing and industrial applications, steel balls, as a key component, play a vital role. Among them, 9.5mm steel balls, with their unique characteristics, hold an important position in numerous application scenarios, especially in bearing applications, where they demonstrate excellent performance.

I. Characteristics of 9.5mm Steel Bearing Balls

High Dimensional Accuracy

The diameter tolerance of 9.5mm steel balls is strictly controlled within a very small range, usually reaching micron - level accuracy. This high - precision dimension ensures that the steel balls can operate stably in precision equipment such as bearings, reducing vibrations and noises caused by dimensional deviations. At the same time, it also improves the overall accuracy and reliability of the equipment.

Excellent Surface Quality

The surface of the steel balls undergoes fine grinding and polishing treatment, resulting in an extremely low surface roughness. The smooth surface not only reduces the friction coefficient between the steelballs and other components, minimizing energy loss, but also effectively prevents wear and corrosion, thus extending the service life of the steel balls. In addition, the good surface quality makes the steel balls roll more smoothly, further enhancing the operating performance of the equipment.

Superior Material Properties

They are generally made of high - quality bearing steel, such as GCr15. These steels have high hardness, high strength, good wear resistance, and fatigue resistance. High hardness enables the steel balls to withstand large loads without easy deformation. High strength ensures the structural integrity of the steel balls under complex working conditions. Wear resistance ensures the dimensional stability of the steel balls during long - term use. Fatigue resistance enables the steel balls to maintain a good working state under frequent alternating loads, greatly improving the reliability and service life of the steel balls.

Good Shape Regularity

The roundness error of 9.5mm steel balls is extremely small, almost approaching an ideal spherical shape. This regular shape makes the steel balls (receive uniform force) during the rolling process, avoiding stress concentration caused by irregular shapes. Thus, it improves the motion stability and reliability of the steel balls, and at the same time reduces the wear on the bearing seat and other related components.

II. Applications in Bearings

Deep - Groove Ball Bearings

In deep - groove ball bearings, 9.5mm steel balls are the core rolling elements. Deep - groove ball bearings mainly bear radial loads and can also bear a certain amount of axial loads. With their high precision, good surface quality, and regular shape, 9.5mm steel balls can roll smoothly in deep - groove ball bearings, effectively reducing friction resistance and improving the rotational accuracy and speed of the bearings. At the same time, their excellent material properties enable the bearings to withstand large loads, making them suitable for various mechanical equipment, such as motors, automobile wheels, and machine tool spindles.

Angular Contact Ball Bearings

Angular contact ball bearings can bear both radial and axial loads simultaneously and can remain stable at high - speed operation. In angular contact ball bearings, 9.5mm steel balls, through reasonable arrangement and matching, can effectively transmit loads, ensuring that the bearings can still work normally under complex stress conditions. Such bearings are commonly used in fields with extremely high requirements for accuracy and reliability, such as aerospace, precision machine tools, and high - speed motors.

Thrust Ball Bearings

Thrust ball bearings are mainly used to bear axial loads. In thrust ball bearings, 9.5mm steel balls can roll smoothly under the action of axial forces, achieving relative movement between shafts. Due to their good load - bearing capacity and wear resistance, thrust ball bearings are widely used in various mechanical equipment that needs to bear axial loads, such as cranes, reducers, and rolling mills.

The application of 9.5mm steel balls in bearings can significantly improve the operating performance of equipment. Their high precision and good surface quality result in higher rotational accuracy, less vibration and noise, and smoother operation of the equipment. At the same time, due to the excellent material properties of the steel balls, the bearings can bear larger loads, improving the work efficiency and reliability of the equipment.

For more information, feel free to contact QIBR