Newsroom

How Do Slewing Bearings Work?

2020-06-18How Do Slewing Bearings Work?

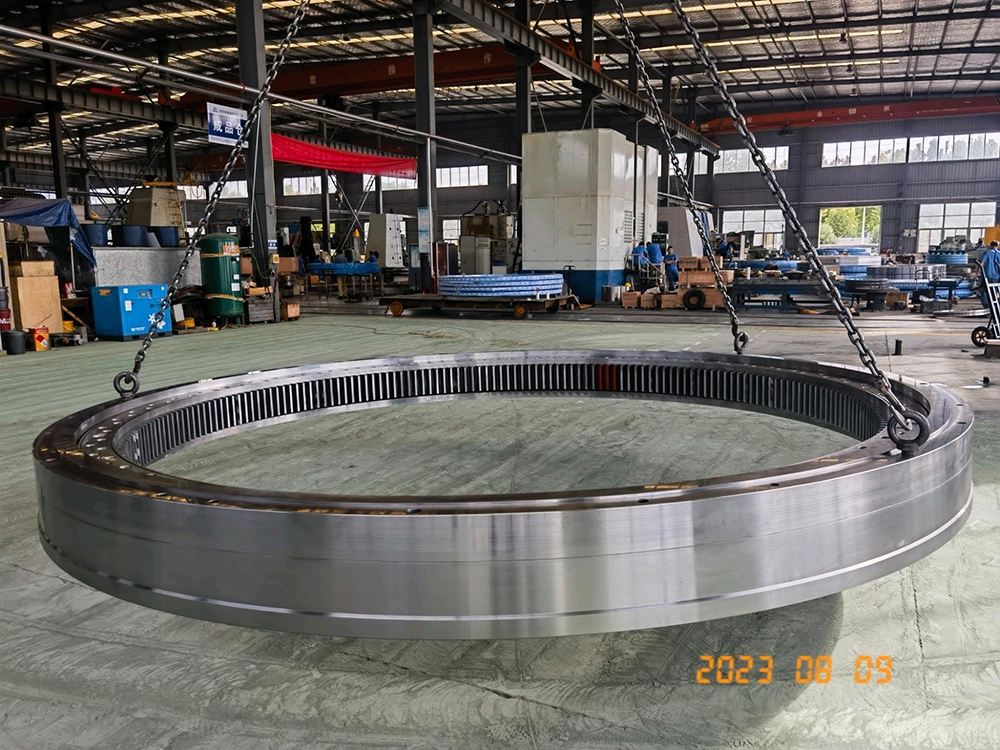

Slewing Bearings, essential components in machinery and industrial applications, operate similarly to traditional bearings but are specialized for rotational movement around a central axis. They utilize bearing races, rolling elements such as balls or cylindrical rollers, and anti-friction components to facilitate smooth rotation.

A rotary bearing typically comprises an outer ring and an inner ring, with one of these rings integrating gear teeth on its inner or outer circumference. These gears engage with corresponding gears on a driver mounted to the structure, enabling the bearing to facilitate controlled rotation.

Between the rings of the rotary bearing lies a lubricated environment containing rolling elements. This setup ensures low friction during rotation, essential for efficient operation over extended periods. Each side of the rotary bearing is equipped with seals to maintain the lubrication and prevent contamination by debris, thereby enhancing longevity and reliability.

Like all bearings, Slewing Bearings are meticulously designed to effectively transmit motion along guided paths. This design feature is crucial in applications where precise and smooth rotational movement is paramount, such as in cranes, excavators, wind turbines, and radar systems.

The functionality of Slewing Bearings underscores their importance in industrial and mechanical systems, where they provide robust support for heavy loads and dynamic movements. Their ability to maintain operational efficiency and reliability in diverse environments makes them indispensable in modern engineering and manufacturing.

In conclusion, Slewing Bearings play a fundamental role in enabling rotational motion with minimal friction and maximum reliability. Their design and construction reflect decades of engineering innovation, ensuring they meet the stringent demands of today's industrial applications.