Newsroom

How is the Soft Zone of a Slewing Bearing Formed?

2024-10-18A slewing bearing is a large bearing capable of bearing combined loads, which can simultaneously withstand significant axial, radial loads, and overturning moments. The positioning requirements for the installation of the soft zone in a slewing bearing are essentially aimed at improving the bearing's lifespan. From both the user and manufacturer perspectives, it is reasonable to install the soft zones of the upper and lower rings of the slewing bearing in optimal positions. Therefore, as a manufacturer of slewing bearings, we accurately mark the position of the soft zone on the slewing bearing.

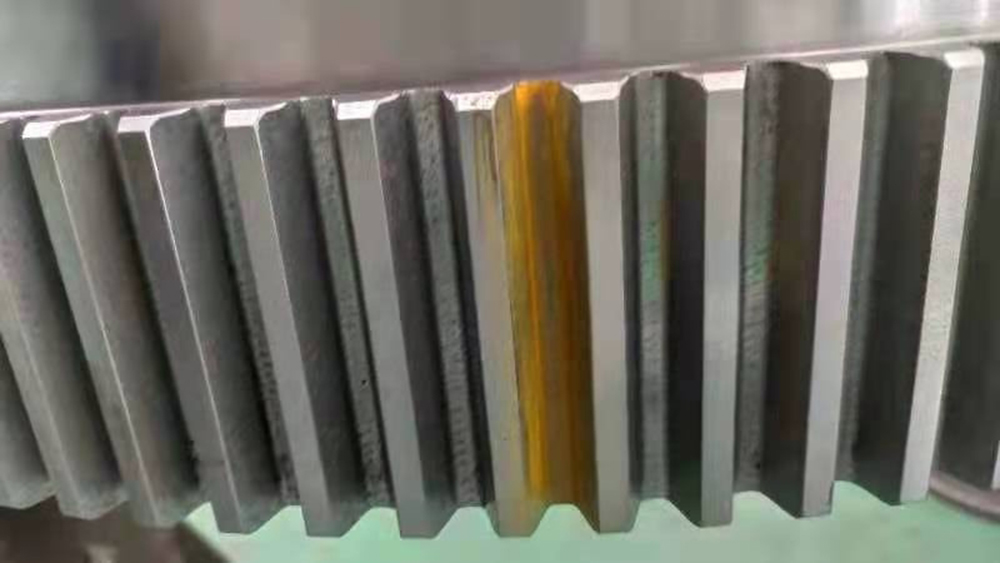

Due to the large diameter of the rolling raceways in slewing bearings, surface hardening is usually employed. This process involves heating the surface of the workpiece that needs to be hardened with an acetylene flame and then cooling it with water. This process is completed continuously. The heating flame gun and water gun are installed together and move circumferentially along the workpiece. When the movement approaches 360 degrees, heating and spraying are immediately stopped, meaning that there should be no overlap between the heated area and the sprayed area. If there is an overlap between these two areas, cracks may occur in the workpiece. The width of the untreated area along the tangential direction is generally about 15 millimeters. This 15-millimeter area in a slewing bearing is referred to as the soft zone. Normally, Fenghe will stamp a steel letter "S" at the position of the soft zone on the workpiece to indicate its specific location.

Basic Structure of Slewing Bearings

Slewing bearings typically consist of an inner ring, an outer ring, rolling elements, and cages. Their design allows them to bear large loads while maintaining smooth rotation. Due to their complex working environment, slewing bearings must possess good wear resistance and strength to ensure stable operation over extended periods.

Definition and Function of soft zones

In a slewing bearing, a soft zone refers to an area that has not been hardened during heat treatment. This part usually surrounds the rolling raceway with a width typically around 15 millimeters. The presence of a soft zone ensures that during operation, the slewing bearing can effectively absorb and distribute loads while preventing cracks or other damage due to temperature changes.

Formation Process of soft zones

Heat Treatment Process

The heat treatment of slewing bearings primarily uses surface hardening technology. In this process, manufacturers use an acetylene flame to heat the surface of the workpiece that needs hardening, followed by rapid cooling with water. This process must be continuous to ensure that there is no overlap between heated and cooled areas. If there is an overlap between these two regions, it may lead to cracks in the workpiece.

Specifically, heating flame guns and water guns move together in a circular motion along the workpiece. When approaching 360 degrees of movement, heating and spraying are immediately stopped to form a uniform hardened area. The untreated 15-millimeter region becomes the soft zone; this design helps improve both toughness and durability during actual applications.

Marking soft zone Positions

To ensure that users can correctly identify soft zone positions during installation, many manufacturers will mark these areas on their products with symbols such as a steel letter "S." This marking not only helps users avoid applying loads on soft zone regions during installation but also assists maintenance personnel in better understanding equipment conditions during routine inspections.

Impact of soft zones on Slewing Bearing Performance

Increasing Service Life

By designing and accurately marking soft zone positions, it is possible to significantly extend the service life of slewing bearings. When loads are applied correctly, wear and fatigue can be effectively reduced, thereby prolonging overall equipment lifespan.

Reducing Failure Risks

If installed incorrectly—particularly by applying loads on soft zone areas—slewing bearings may experience issues such as jamming or reduced mobility. Therefore, it is crucial during installation to ensure that soft zone areas are positioned in low or non-load zones to minimize failure risks.

Maintenance and Care

Regularly checking the operational status of slewing bearings and ensuring adequate lubrication are essential measures for maintaining normal operation. Insufficient lubrication may lead to increased friction, affecting mobility. Thus, during maintenance, particular attention should be paid to any unusual wear or damage signs in the soft zone area.

Conclusion

The soft zone in a slewing bearing is an essential structure formed through precise control during heat treatment; its design directly influences both performance and service life. Proper installation and maintenance can effectively enhance equipment operating efficiency while reducing failure rates. Understanding how soft zones are formed and their functions is crucial for professionals in the engineering machinery industry; it aids in better management and maintenance of equipment, ensuring long-term stable operation.