Newsroom

How to choose the type of slewing bearing?

Technical Analysis and Application Guide for Slewing Bearings

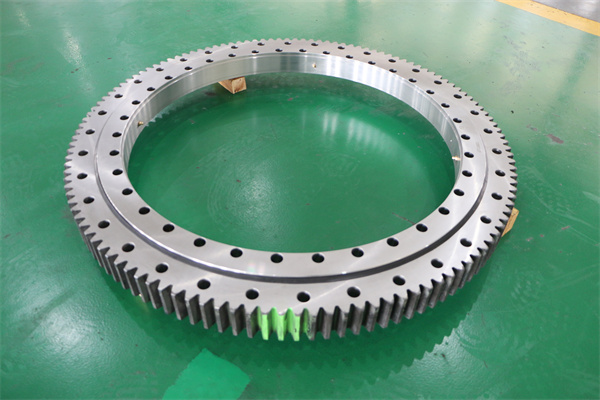

Slewing bearings, also known as rotary bearings or turntable bearings, are crucial components in various heavy machinery and precision equipment. This guide provides an in-depth analysis of four major types of slewing bearings, their technical specifications, and industrial applications.

I. Single-Row Cross Roller Slewing Bearing

The single-row cross roller slewing bearing is a high-precision component designed for applications requiring compactness and high load capacity. Its unique structure consists of two concentric rings with cylindrical rollers arranged in a 1:1 cross pattern. The rollers are positioned at a 45° contact angle, enabling the bearing to handle combined axial, radial, and moment loads simultaneously.

Key Specifications:

- Roller Surface Finish: Precision grinding achieves a surface roughness of Ra0.2μm or better, ensuring smooth operation and reduced friction.

- Axial Clearance: Adjustable within 0.02-0.05mm, allowing for precise alignment and minimal play.

- Load Capacity: Axial load (Fa) ≥ 500kN, radial load (Fr) ≥ 300kN, and moment load (M) ≥ 200kN·m.

- Material: High-carbon chromium steel rollers with vacuum-degassed bearing steel rings for enhanced durability and fatigue resistance.

Performance Advantages:

1. Compact Design: The cross-roller arrangement reduces the overall height by 40% compared to traditional designs, making it ideal for space-constrained applications.

2. High Rigidity: The orthogonal roller configuration increases the section modulus by over 60%, providing exceptional stiffness under heavy loads.

3. Precision Operation: Achieves ISO P5-grade accuracy, suitable for high-precision positioning systems.

4. Low Friction: Optimized roller geometry and surface finish result in a friction coefficient as low as 0.0015.

Applications:

- CNC Rotary Tables: Used in machining centers for multi-axis operations, offering ±2" positioning accuracy.

- Radar Elevation Mechanisms: Ensures reliable performance in harsh environments with a service life exceeding 30,000 hours.

- Industrial Robots: Provides ±0.01mm repeatability in robotic joints for precision assembly tasks.

- Medical Imaging Equipment: Operates at noise levels below 45dB, making it suitable for CT scanners and MRI machines.

II. Single-Row Four-Point Contact Ball Bearing

The single-row four-point contact ball bearing is designed for applications requiring high load capacity and compact dimensions. Its unique raceway geometry creates four contact points between the balls and raceways, enabling it to handle combined loads efficiently.

Key Specifications:

- Dynamic Load Rating (C): 1.2×10⁶N

- Static Load Rating (C₀): 8×10⁵N

- Tilt Tolerance: ≤0.5°, ensuring stable operation under misalignment conditions.

- Breakaway Torque: ≤5N·m, facilitating smooth startup even under heavy loads.

Performance Features:

1. High Load Capacity: The four-point contact design distributes loads evenly, reducing stress concentrations.

2. Low Maintenance: Sealed units with grease lubrication provide long service intervals.

3. Temperature Resistance: Operates reliably in temperatures ranging from -40°C to +80°C.

Applications:

- Welding Positioners: Supports 200A welding currents with precise rotation control.

- Packaging Turntables: Accommodates mounting tolerances of up to ±3°, ensuring smooth operation in high-speed packaging lines.

- Solar Trackers: Designed for outdoor use, withstanding environmental challenges while maintaining precise sun-tracking accuracy.

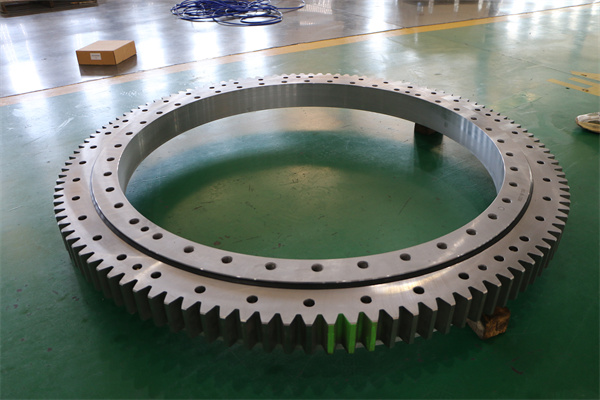

III. Three-Row Roller Combination Slewing Bearing

The three-row roller combination slewing bearing is the most robust design, capable of handling extreme loads in heavy machinery. It features three independent roller paths for axial, radial, and moment loads, allowing for precise load distribution.

Key Specifications:

- Axial Load Capacity: 2000-12000kN

- Radial Load Capacity: 1500-8000kN

- Moment Load Capacity: 5000-30000kN·m

- Material: Case-hardened steel with a surface hardness of HRC58-62 and a hardened depth of 3-5mm.

Structural Features:

1. Independent Roller Paths: Each row of rollers is optimized for specific load types, ensuring maximum efficiency.

2. Adjustable Clearance: Split-ring design allows for 0.1mm-level clearance adjustments during installation.

3. Advanced Sealing System: Triple-lip seals combined with labyrinth structures provide IP67-level protection against contaminants.

Applications:

- Bucket-Wheel Excavators: Supports excavation rates of 70m³/h in mining operations.

- Marine Cranes: Complies with CCS (China Classification Society) standards for offshore applications.

- Ladle Turrets: Handles 300-ton molten steel ladles in steelmaking plants.

IV. Double-Row Angular Contact Ball Bearing

The double-row angular contact ball bearing is designed for applications requiring high axial and moment load capacity. Its asymmetrical design features two rows of balls with different diameters, optimizing load distribution and stiffness.

Key Specifications:

- Axial Stiffness: 5000N/μm

- Radial Stiffness: 3000N/μm

- Speed Limit: 120rpm under oil-mist lubrication.

- Preload Adjustment Range: 0.05-0.15mm.

Design Highlights:

1. Modified Raceways: Elliptical raceway profiles are used when radial loads exceed 10% of axial loads (Fr > 0.1Fa).

2. Cage Materials: Phenolic resin or copper alloy cages provide low friction and high durability.

3. Mounting Flexibility: Open-type design simplifies installation and maintenance.

Applications:

- Tower Cranes: Used in QTZ250 models with a maximum load moment of 2500kN·m.

- Truck Cranes: Supports QY100K models with a maximum lifting height of 98m.

- Heavy-Duty Turntables: Ideal for applications requiring medium to large diameters and high load capacities.

Conclusion

Slewing bearings are critical components in modern machinery, offering tailored solutions for a wide range of applications. From compact single-row designs for precision equipment to robust three-row configurations for heavy machinery, each type of slewing bearing is engineered to meet specific performance requirements. By understanding the technical specifications and application considerations outlined in this guide, engineers and maintenance professionals can select the optimal bearing solution for their needs, ensuring reliable operation and extended service life.