Newsroom

How to store finished angular contact ball bearings?

2024-10-25The storage of finished angular contact ball bearings involves several meticulous steps aimed at protecting the bearings from damage during storage and transportation, particularly from rust and corrosion. Here is a breakdown of the key steps and precautions for the proper storage of finished angular contact ball bearings:

1.Preparatory Work

Cleaning Tools: Prepare cleaning tools like tissues, cotton swabs, and brushes to remove dust and dirt from the surface of the angular contact ball bearings.

Lubricant Selection: Choose appropriate rust-prevention or lubrication oil based on the type of bearing and storage environment.

Sealing Materials: Prepare sealing covers, packaging bags, or rust-preventive wrapping paper to ensure the bearings can be stored in a sealed environment.

2.Cleaning Steps

Initial Cleaning: Use tissues or cotton swabs to remove surface dust and dirt from the angular contact ball bearings.

Deep Cleaning: Clean the inner and outer surfaces of the bearings with a brush to ensure no impurities are left.

Cleaning Agent Treatment: Use a specialized cleaning agent to thoroughly clean the bearings, removing all dirt and grease. This step is crucial as a dirty surface can reduce the effectiveness of rust-prevention oil.

3.Drying Process

After cleaning, the bearings should be dried immediately to remove any moisture from the surface. This can be done by air-drying or using drying equipment to ensure the bearings are completely moisture-free.

4.Oil Coating and Sealing

Oil Application: Apply a uniform layer of rust-prevention oil on the surface of the bearings. Be mindful of the amount of oil used, ensuring the surface is well-coated but without excessive waste.

Oil Film Inspection: Carefully check the oil film after application to ensure it is evenly applied without gaps. Any gaps in the oil film can lead to corrosion in those areas.

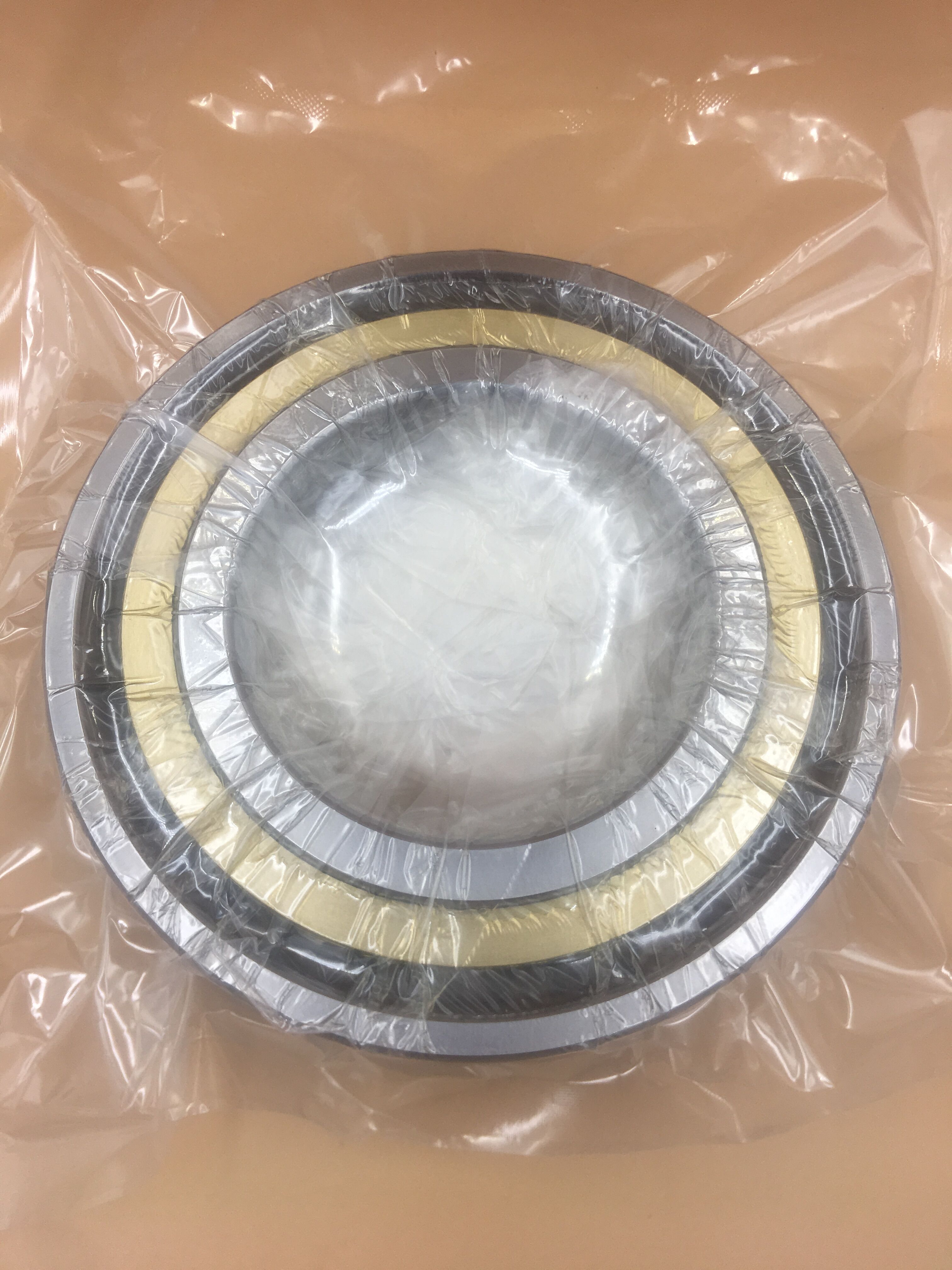

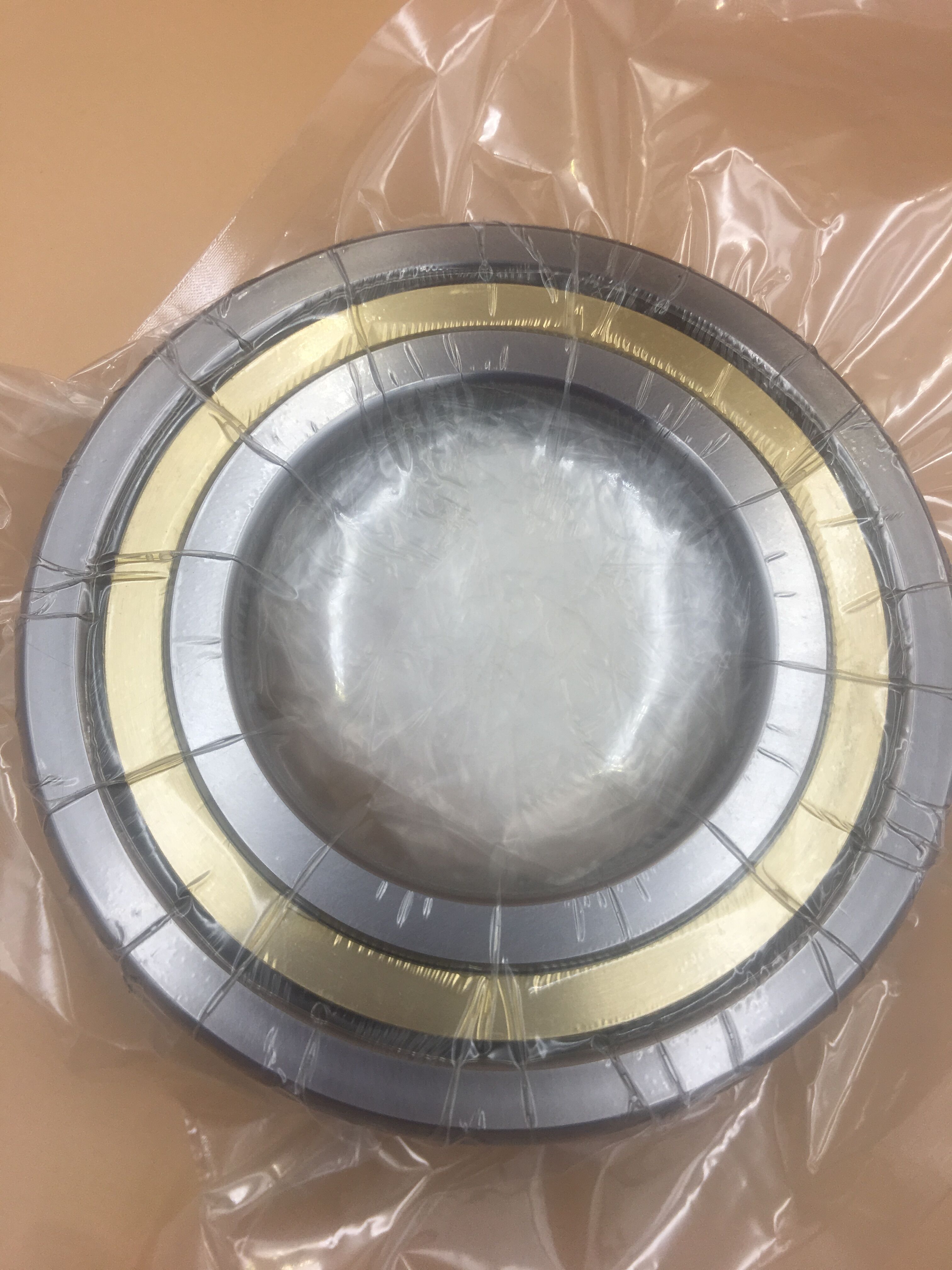

5.Packaging and Sealing

Packaging: Place the rust-protected bearings in a sealing cover, packaging bag, or rust-preventive wrapping paper, ensuring it is fully sealed.

Labeling Information: Label the storage container with the bearing model, quantity, and the date of storage for easy future reference.

6.Storage Environment Requirements

Temperature Control: Keep the storage environment within an appropriate temperature range, avoiding extremes that could cause the rust-preventive oil to deteriorate.

Humidity Control: Maintain a relative humidity of 45%-60% in the warehouse, as high humidity can cause the bearings to rust.

Clean Environment: Ensure the storage area is clean and dust-free, and avoid exposure to corrosive gases that could damage the bearings.

7.Regular Inspections

According to the product’s rust-prevention guidelines, the stored angular contact ball bearings should be inspected every 10-12 months. If any signs of rust are found, the bearings should be re-sealed and oiled promptly.

The storage of finished angular contact ball bearings is a comprehensive process requiring careful handling and strict environmental control. By following proper storage methods and maintaining optimal storage conditions, you can ensure that the bearings remain in good condition during storage and transportation, preventing rust and corrosion issues.

For more information, feel free to contact QIBR