Newsroom

What are bearing seals? How are bearing seals classified and selected?

2023-07-19Since the bearing contains a large amount of fluid grease, to prevent the leakage of grease during the operation of the bearing, the bearing must be sealed. This is the beginning of bearing sealing. Later in production and life, it was found that bearings are often used in highly polluted, dusty and humid environments, and pollutants will cause bearing wear and moisture will corrode the bearing. Therefore, sealing plays an increasingly important role in it.

From the sealing form, seals are mainly divided into contact type and non-contact type. In non-contact seals, there is no direct contact between the sealing ring and the rolling element, and lubricant is filled, so it is more suitable for high-speed scenes; contact seals are directly pressed on the shaft, and the sealing performance is better, but due to direct contact, the friction torque and temperature rise are higher. In addition, since the lip rotates in contact with the shaft, the type of contact seal determines the linear speed of the sealing part.

Non-contact sealing

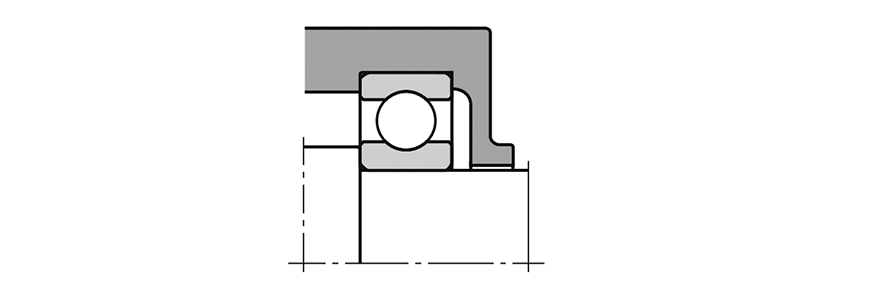

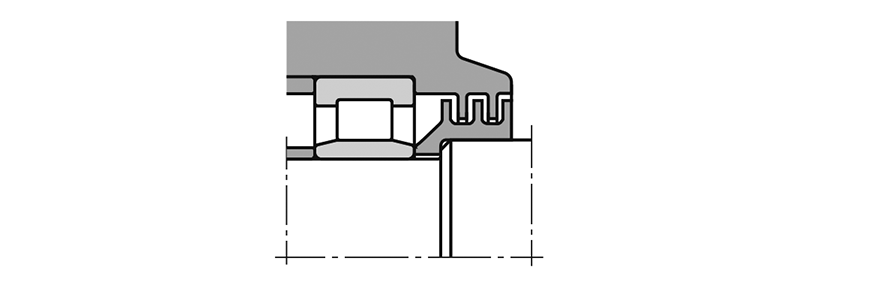

• The simplest configuration of non-contact seal is a gap seal, as shown in the figure above. To enhance the sealing effect, the clearance between the shaft and the bearing housing should be as small as possible.

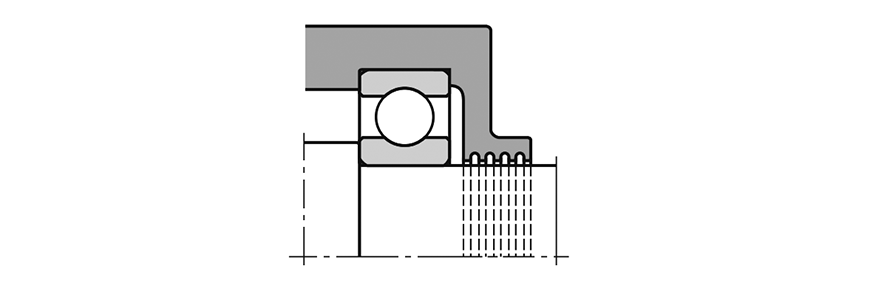

• The oil groove seal evolved from the gap seal has several concentric oil grooves on the inner diameter of the bearing seat, which has a better sealing effect. The lubricant stored in the oil groove can effectively prevent the entry of pollutants, dust, etc.

• The bearing housing has an oil groove on the inner diameter, and the shaft can also have an oil groove, which will have a better sealing effect.

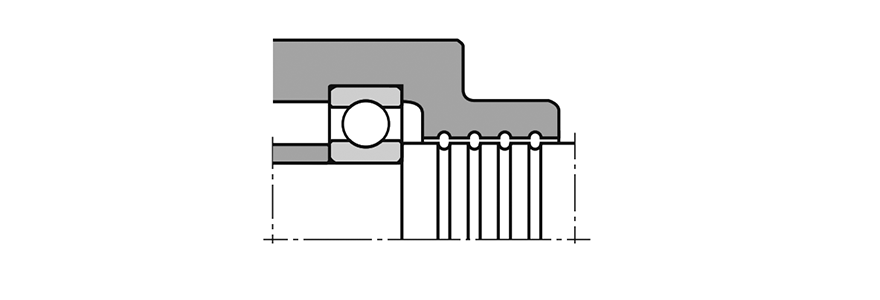

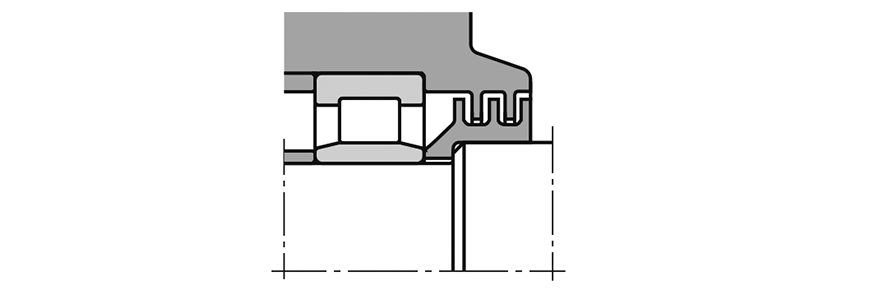

• Since the shaft, bearing housing and bearing are assembled, and the bearing is to rotate continuously, there will be large or small gaps where the devices are joined, which become windows for external contamination to enter or internal lubrication to spread. In order to slow down this process, the labyrinth seal was invented. As the name suggests, it forms a maze-like passage.

• Labyrinth seals are divided into axial, radial and self-aligning types. Radial labyrinth seals are mostly used in split bearing seats. Compared with axial labyrinth seals, radial labyrinth seals have better sealing effects. The labyrinth passage of the self-aligning labyrinth seal is inclined, so even if the shaft is tilted relative to the bearing seat, it will not cause contact with the raised part of the labyrinth.

Contact sealing

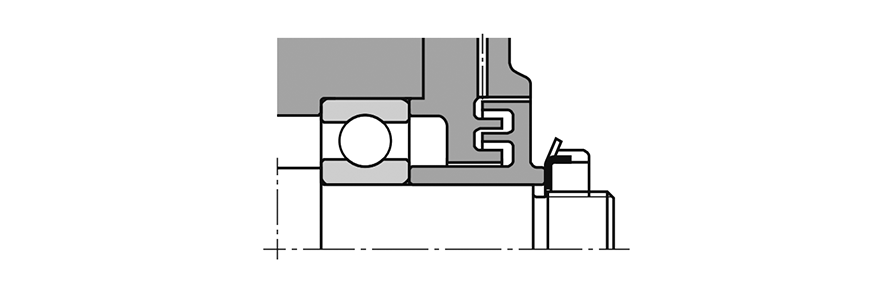

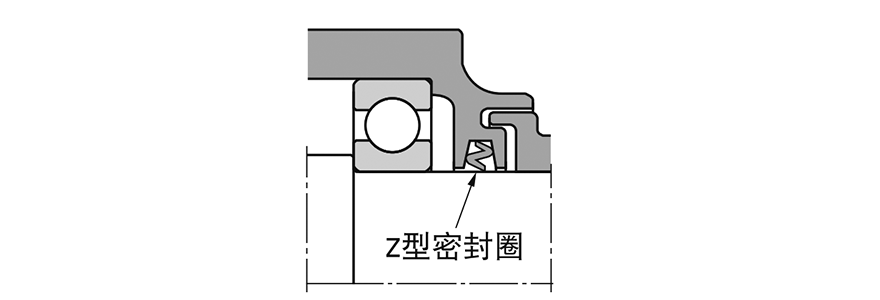

• There are two types of contact seals: line contact and surface contact. Common line contact seals include Z-type seals, which are contact seal rings with a Z-shaped cross-section to form a grease seal.

• Common surface contact types include V-type seals, in which the sealing lip is in axial contact, the contact surface is larger, and the sealing effect is enhanced. At the same time, the special design of the V-type seal can use centrifugal force to throw out invading foreign matter and water.

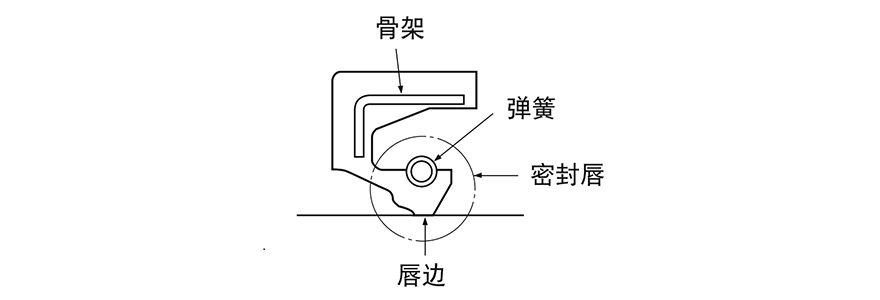

• Oil seals are the most commonly used contact seals. There are more than 14,000 SKF CR series oil seals, which are suitable for various scenarios. They are usually spring-pressurized. Oil seals also have multiple layers, double layers, or line contact, surface contact and other designs, and the materials are also diverse.

For more information about the bearings, don't hesitate to contact QIBR.