Newsroom

What are Features, Advantages, and Applications of QIBR Slewing Bearings?

2022-10-13What are Features, Advantages, and Applications of QIBR Slewing Bearings

QIBR slewing bearing are replaceable with QIBR slewing bearing.

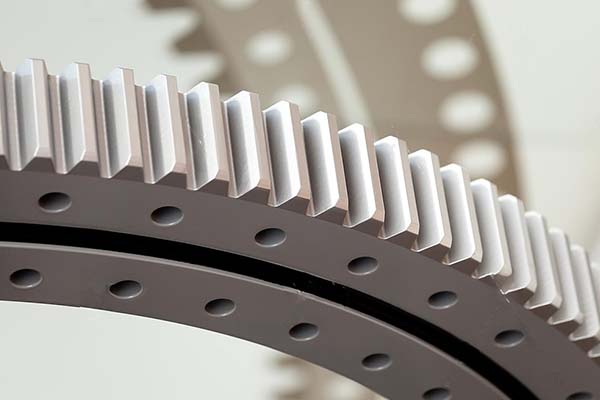

Slewing bearings, also known as slewing rings, are large-size rolling bearings designed to accommodate axial, radial, and moment loads acting in various directions. Among the manufacturers of slewing bearings, QIBR Industries stands out for its innovative designs and high-quality products. This article explores the features, advantages, and applications of QIBR slewing bearings, emphasizing their significance in modern machinery and engineering.

Features of QIBR Slewing Bearings

QIBR slewing bearings are characterized by several key features that enhance their performance and reliability:

1. Construction and Design: QIBR slewing bearings, particularly the YRT standard series, are designed with three rows of crossed rollers. This configuration allows for the accommodation of both axial and radial loads, providing superior load distribution and stability. The use of 100Cr6 through-hardened steel ensures high durability, while bronze cages enhance the bearings' performance under varying conditions.

2. Precision Engineering: The inner and outer surfaces of QIBR slewing bearings are finely ground to achieve micrometric rotation precision. This level of precision is crucial for applications where accurate positioning is necessary, such as in machine tools and robotics.

3. High Load Capacity: QIBR slewing bearings are engineered to handle substantial axial, radial, and moment loads, making them suitable for heavy-duty applications. Their robust design minimizes the risk of premature failure, ensuring long-term reliability.

4. Customizability: QIBR offers customizable solutions tailored to specific application requirements. This flexibility allows for the integration of specialized materials, coatings, and design modifications to meet the unique needs of various industries.

5. Sealing and Lubrication: Effective sealing mechanisms are incorporated to keep lubricants in and contaminants out, which is essential for maintaining performance and extending the service life of the bearings. Relubrication options further enhance their maintenance and operational efficiency.

Advantages of QIBR Slewing Bearings

The advantages of QIBR slewing bearings make them a preferred choice in numerous applications:

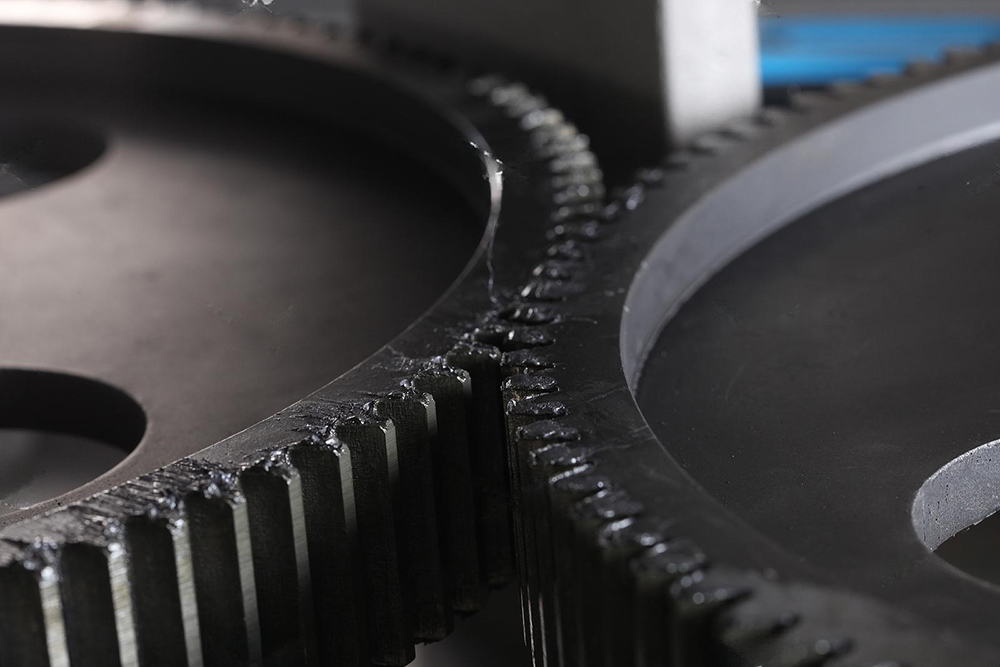

1. Superior Load-Carrying Capacity: The robust internal structure of QIBR slewing bearings allows them to withstand high radial and axial loads, making them ideal for heavy machinery and equipment. This capability ensures stability and durability, reducing downtime and maintenance costs.

2. Precise Rotational Movements: The design of QIBR slewing bearings facilitates precise rotational movements, which is critical in applications such as robotics, aerospace, and industrial automation. Accurate positioning minimizes operational errors, enhancing overall efficiency and product quality.

3. Versatility Across Industries: QIBR slewing bearings are used in a wide range of industries, including construction, renewable energy, aerospace, and manufacturing. Their versatility allows them to meet the demands of various applications, from heavy machinery to precision instruments.

4. Durability and Longevity: Designed to operate in harsh environments, QIBR slewing bearings exhibit excellent durability and longevity. Their ability to withstand extreme conditions makes them suitable for outdoor applications, such as wind turbines and offshore cranes.

5. Reduced Maintenance Needs: The advanced design and materials used in QIBR slewing bearings contribute to lower maintenance requirements. This feature is particularly beneficial in industries where machinery operates continuously and reliability is paramount.

Applications of QIBR Slewing Bearings

QIBR slewing bearings find applications in diverse fields due to their unique features and advantages:

1. Heavy Machinery: In the construction industry, QIBR slewing bearings are integral components in cranes, excavators, and earthmovers. They enable 360-degree rotation and support heavy loads, which is essential for efficient and safe operations.

2. Aerospace and Defense: The aerospace sector relies on QIBR slewing bearings for applications such as radar systems and missile launchers, where precision and reliability are critical. These bearings ensure accurate movement and positioning of vital components.

3. Renewable Energy: In wind turbines and solar tracking systems, QIBR slewing bearings support the rotation of nacelles and solar panels, optimizing energy generation by allowing them to track the sun and wind direction effectively.

4. Robotics and Automation: QIBR slewing bearings are used in industrial robots and automated material handling systems, providing the necessary precision and control for efficient operation in manufacturing and logistics.

5. Marine and Offshore Applications: In marine environments, QIBR slewing bearings are crucial for equipment such as ship steering mechanisms and offshore cranes, where they facilitate smooth and reliable operation under challenging conditions.

Conclusion

QIBR slewing bearings represent a significant advancement in bearing technology, offering features and advantages that cater to a wide range of industrial applications. Their robust construction, precision engineering, and high load-carrying capacity make them indispensable in modern machinery. As industries continue to evolve, the demand for reliable and efficient components like QIBR slewing bearings will only increase, driving innovation and performance across various sectors.