Newsroom

What are Features, Applications, and Maintenance of Bearing 1204?

What are Features, Applications, and Maintenance of Bearing 1204?

Introduction

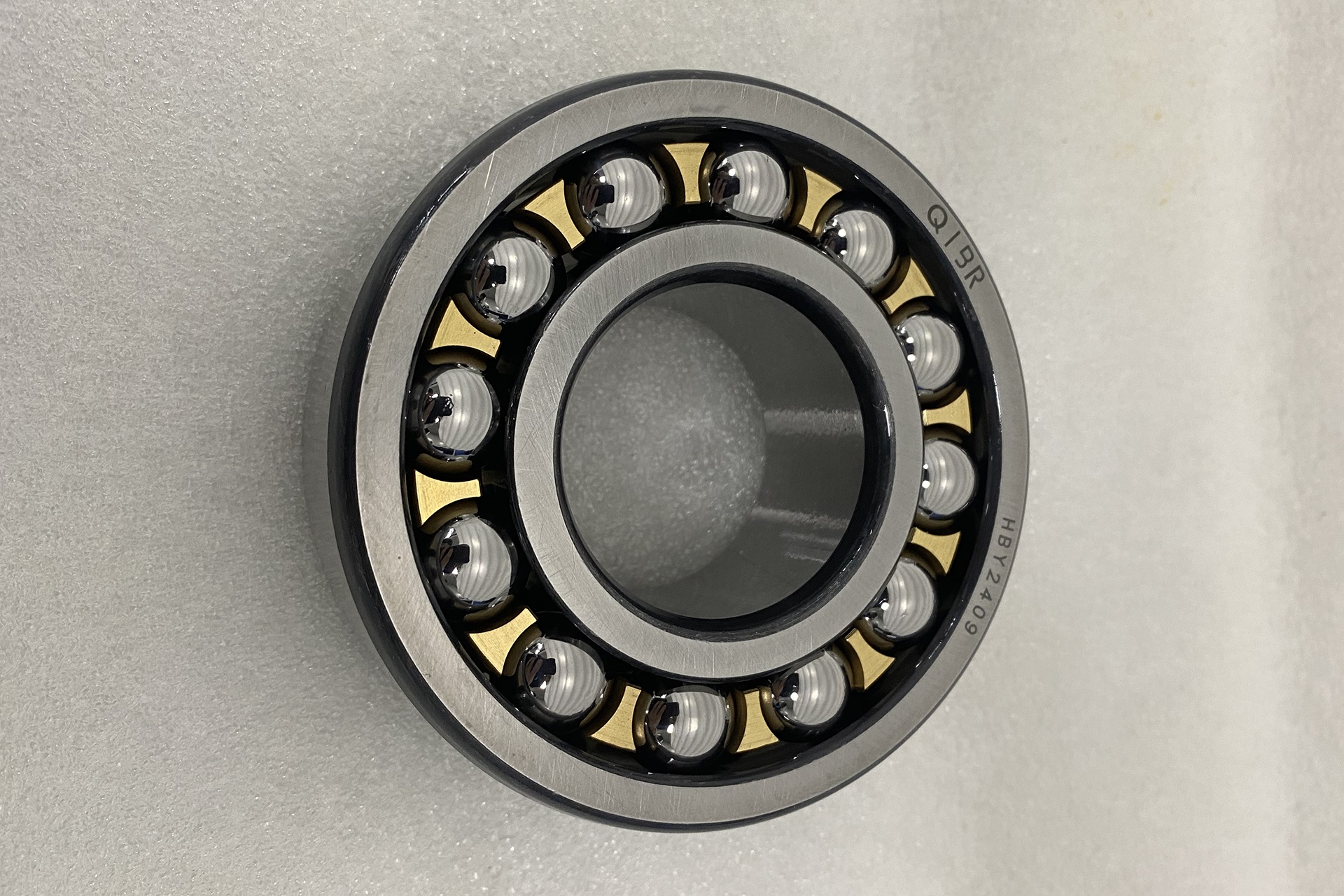

Bearings are critical components in various mechanical systems, enabling smooth motion and reducing friction between moving parts. Among the myriad types of bearings available, the Bearing 1204 stands out due to its specific design and versatile applications. This article delves into the features, applications, and maintenance of Bearing 1204, providing a comprehensive understanding of its role in modern machinery.

What is Bearing 1204?

Bearing 1204 is a type of deep groove ball bearing, which is one of the most commonly used bearings in industrial and mechanical applications. It is characterized by its simple design, high durability, and ability to handle both radial and axial loads. The "1204" designation refers to its specific dimensions and design specifications, which are standardized for compatibility across various systems.

Key Specifications of Bearing 1204:

Inner Diameter (ID): 20 mm

Outer Diameter (OD): 47 mm

Width: 14 mm

Material: Typically made from high-quality chrome steel or stainless steel for corrosion resistance.

Load Capacity: Designed to handle moderate to high radial and axial loads.

Speed Rating: Suitable for high-speed applications due to its low friction design.

Features of Bearing 1204

1. Deep Groove Design

The deep groove design of Bearing 1204 allows it to accommodate both radial and axial loads, making it suitable for a wide range of applications. The grooves in the inner and outer rings enable smooth rotation and efficient load distribution.

2. High Precision

Bearing 1204 is manufactured to high precision standards, ensuring minimal vibration and noise during operation. This makes it ideal for applications requiring smooth and quiet performance, such as in electric motors and precision machinery.

3. Durability

Constructed from high-quality materials, Bearing 1204 is highly durable and resistant to wear and tear. This ensures a long service life even under demanding operating conditions.

4. Low Maintenance

The sealed or shielded variants of Bearing 1204 require minimal maintenance, as they are pre-lubricated and protected from contaminants like dust and moisture.

5. Versatility

Bearing 1204 is compatible with various types of machinery and equipment, making it a versatile choice for engineers and designers.

Applications of Bearing 1204

Bearing 1204 is widely used across multiple industries due to its robust design and reliable performance. Some of the key applications include:

1. Electric Motors

In electric motors, Bearing 1204 ensures smooth rotation of the rotor, reducing energy loss and improving efficiency. Its ability to handle high speeds makes it a preferred choice for motor manufacturers.

2. Automotive Industry

Bearing 1204 is used in various automotive components, such as alternators, water pumps, and transmission systems. Its durability and load-bearing capacity make it suitable for the demanding conditions of automotive applications.

3. Industrial Machinery

In industrial machinery, Bearing 1204 is employed in conveyor systems, pumps, and gearboxes. Its ability to handle both radial and axial loads ensures reliable performance in heavy-duty applications.

4. Household Appliances

Bearing 1204 is also found in household appliances like washing machines, refrigerators, and fans. Its low noise operation and long service life contribute to the overall efficiency and durability of these appliances.

5. Agricultural Equipment

In agricultural machinery, Bearing 1204 is used in equipment like tractors and harvesters. Its resistance to harsh environmental conditions ensures reliable performance in the field.

Maintenance of Bearing 1204

Proper maintenance is essential to ensure the longevity and optimal performance of Bearing 1204. Here are some key maintenance tips:

1. Regular Lubrication

Although many Bearing 1204 units come pre-lubricated, regular lubrication is necessary to reduce friction and prevent wear. Use the recommended lubricant for your specific application.

2. Inspection

Periodically inspect the bearing for signs of wear, such as pitting, cracks, or discoloration. Early detection of issues can prevent costly repairs or replacements.

3. Cleaning

Keep the bearing clean and free from contaminants like dust and debris. For sealed or shielded bearings, ensure that the seals are intact and functioning properly.

4. Proper Installation

Ensure that the bearing is installed correctly, with the right alignment and fit. Improper installation can lead to premature failure.

5. Monitor Operating Conditions

Keep an eye on the operating conditions, such as temperature and load. Excessive heat or overloading can damage the bearing and reduce its lifespan.

Advantages of Bearing 1204

Cost-Effective: Bearing 1204 offers excellent performance at a competitive price, making it a cost-effective choice for many applications.

Wide Availability: Due to its standardized design, Bearing 1204 is readily available from most bearing suppliers.

Ease of Replacement: Its common dimensions and design make it easy to replace in existing systems.

Energy Efficiency: The low friction design of Bearing 1204 contributes to energy savings in machinery and equipment.

Conclusion

Bearing 1204 is a versatile and reliable component that plays a crucial role in various mechanical systems. Its deep groove design, high precision, and durability make it suitable for a wide range of applications, from electric motors to agricultural equipment. By following proper maintenance practices, users can ensure the longevity and optimal performance of Bearing 1204, making it a valuable investment for any mechanical system.

Whether you are an engineer, technician, or hobbyist, understanding the features and applications of Bearing 1204 can help you make informed decisions and achieve better results in your projects.