Newsroom

What are the advantages and disadvantages of nylon cages?

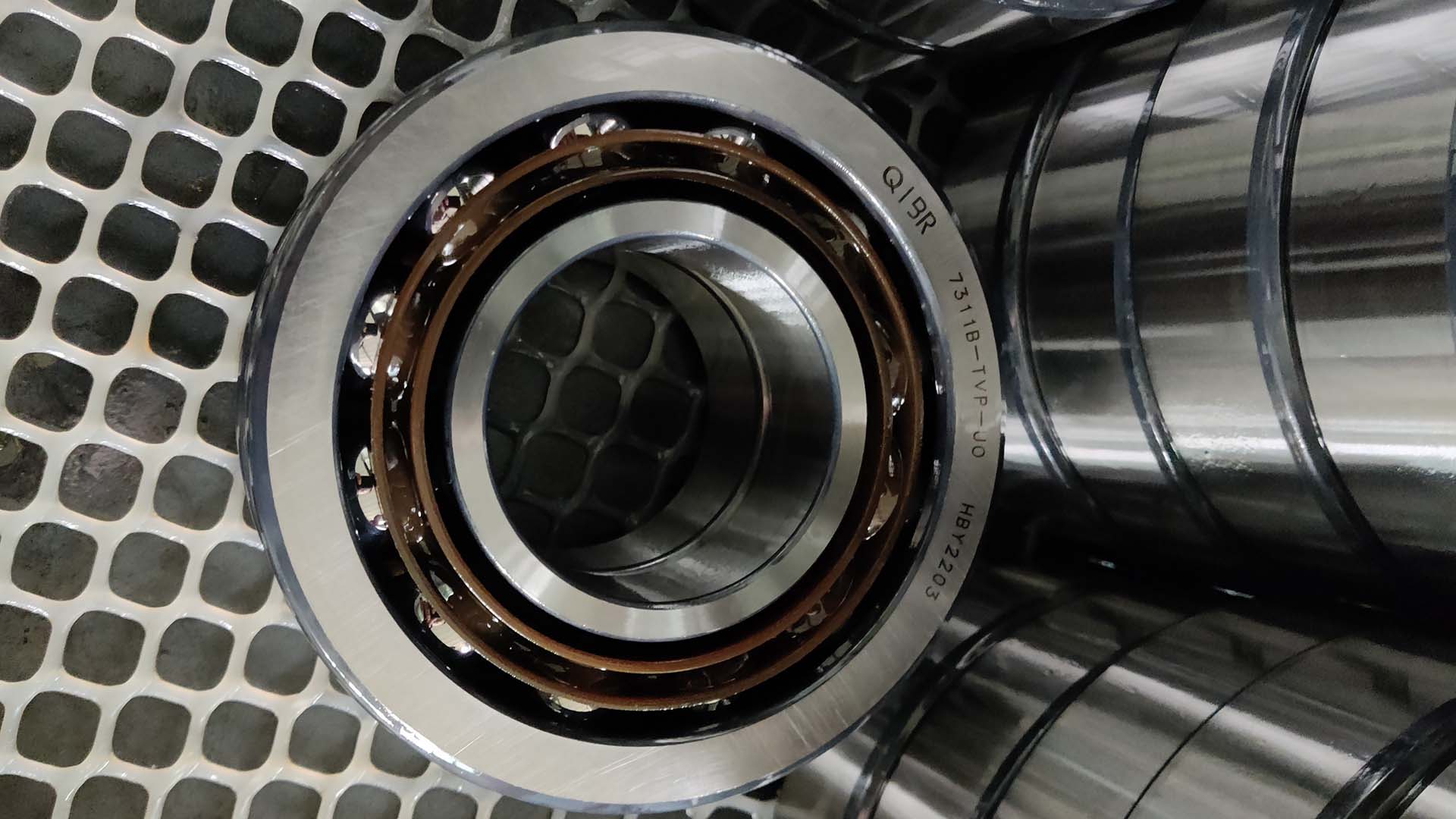

2024-08-09Rolling bearings come in two structural types: with and without cages. Large bearings, which typically need to bear heavier loads, may not have cages, allowing the rolling elements to fully occupy the space between the inner and outer raceways. However, most small and medium-sized rolling bearings are equipped with cages. The primary functions of the cage are:

I.To maintain equal spacing between the rolling elements, ensuring they are evenly distributed around the circumference of the raceway, preventing collision and friction between them.

II.To guide and drive the rolling elements to roll correctly on the raceway.

III.The cage space can be used to store lubricating grease.

IV.In separable bearings, the cage holds the rolling elements together with one ring, preventing them from falling out.

Nylon bearing cages have several advantages, including low vibration, low noise, reduced heat generation, high load capacity, and the ability to increase the bearing's maximum speed and lifespan. They can operate stably over a long period within a temperature range of -40°C to +80°C and are compatible with bearing lubricants. Nylon bearing cages are suitable for use in motors, machine tools, gear shafts, pumps, compressors, and other applications.

1. As nylon cages are increasingly used, what are their advantages?

Nylon bearing cages are a new generation product that replaces copper and iron cages. Compared to metal cages, nylon cages offer several advantages:

I.Lightweight and Flexibility: Nylon cages are lighter than metal cages, which not only reduces the overall weight of the bearing but also increases its flexibility. This is particularly beneficial for electrical and power-saving products where lightweight construction is essential.

II.Low Noise Characteristics: Nylon materials have excellent vibration damping and sound absorption properties, effectively reducing the noise generated during bearing operation, making them the preferred material for manufacturing quiet bearings.

III.Low Friction: Nylon cages generate less friction with rolling elements compared to metal cages, which helps extend the bearing's service life and reduce energy loss.

IV.Production Efficiency and Cost Advantages: The manufacturing process of nylon cages is relatively simple, significantly improving production efficiency and reducing costs, especially in mass production.

2. Despite the many advantages of nylon cages, they also have several disadvantages during bearing usage, mainly:

I. Temperature Limitation: Nylon cages can only operate at normal temperatures and are not suitable for high-temperature environments, which limits their application in high-temperature equipment.

II. Limited Compression Strength: Nylon has lower compressive strength compared to metals, resulting in lower load-bearing capacity. Therefore, in situations requiring high load capacity, other stronger materials might be necessary.

III. Sensitivity to Corrosion: Nylon is more susceptible to chemical corrosion and is not suitable for use in corrosive environments, limiting its applicability in certain specific applications.

3. Application Recommendations:

When selecting a bearing cage, it's important to weigh the specific usage requirements. Nylon cages are ideal for applications that demand low noise, lightweight, and cost efficiency, such as electrical appliances and quiet devices. However, in environments with high temperatures, heavy loads, or severe chemical corrosion, metal cages are more appropriate to ensure stable operation and long-term reliability of the bearings.

In conclusion, while nylon cages offer numerous advantages, it is crucial to make a reasonable choice based on the specific working conditions and requirements to ensure the optimal performance and longevity of the bearings in various operating environments.

For more information, feel free to contact QIBR