Newsroom

What are the structural variations of double row angular contact ball bearings?

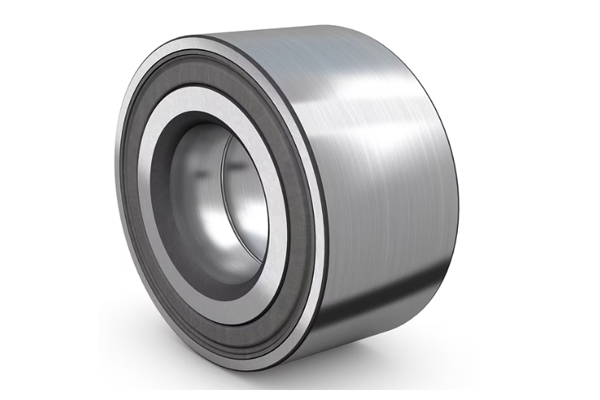

2025-03-17Double row angular contact ball bearings are characterized by their ability to simultaneously accommodate both radial and axial combined loads while limiting axial displacement of the shaft in both directions. Compared to double-direction thrust ball bearings, these bearings have a higher limiting speed, a 32° contact angle, good rigidity, and a high resistance to overturning moments. They are widely used in the front wheel hubs of automobiles (some models also use double-row tapered roller bearings of the same size).

Variations in the Structure of Double Row Angular Contact Ball Bearings:

1.Type A (Outer Diameter ≤ 90mm – Standard Design):

These double row angular contact ball bearings do not have a filling slot, allowing them to withstand equal axial loads in both directions. They feature a lightweight, glass fiber-reinforced nylon 66 cage, which minimizes temperature rise during operation.

2.Type A (Outer Diameter > 90mm – Standard Design):

These double row angular contact ball bearings have a filling slot on one side and are equipped with either a stamped steel cage or a solid brass cage.

3.Type E (Enhanced Structure):

Double row angular contact ball bearings of this type have a filling slot on one side, allowing for the installation of more steel balls, thereby increasing their load-carrying capacity.

4.Shielded and Sealed Variants:

Both Type A and Type E designs are available with shields (non-contact) or seals (contact) on both sides. Sealed bearings are pre-filled with anti-corrosion lithium-based grease, suitable for operating temperatures ranging from -30°C to +110°C. These bearings do not require re-lubrication during use and should not be heated or cleaned before installation.

When installing double row angular contact ball bearings, special attention should be paid to the presence of a filling slot. Although the bearing can accommodate axial loads in both directions, the main axial load should not be applied through the side with the filling slot.

For more information, feel free to contact QIBR