Newsroom

What should be noted when installing and disassembling insert ball bearings?

2017-01-03Installation and Disassembly Guide for Insert Ball Bearings

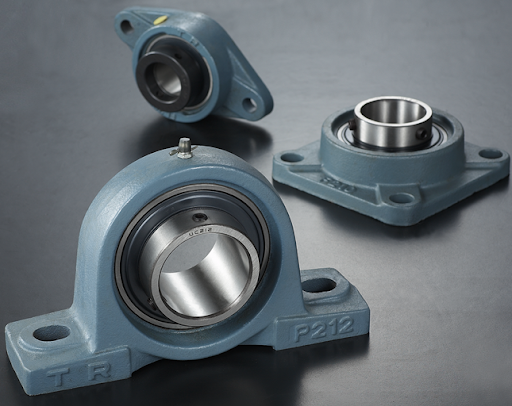

The outer diameter surface of the outer ring of an insert ball bearing is spherical and can be fitted into the corresponding concave spherical surface of the bearing housing to play a self-aligning role. In fact, it is a variant of a deep groove ball bearing. Insert ball bearings are mainly used to bear a combined radial and axial load with the radial load as the main component, and generally are not suitable for bearing the axial load alone. Insert ball bearings can be divided into three categories according to the way of cooperation with the shaft: insert ball bearings with set screws, insert ball bearings with taper, and insert ball bearings with an eccentric sleeve.

The size of the axial clearance affects its normal operation.

An insert ball bearing consists of basic components such as an inner ring, an outer ring, balls, a cage, and a seal ring. This type of bearing does not allow the shaft to be inclined relative to the housing, and an additional axial force will be generated under the action of a radial load. The size of the axial clearance of an insert ball bearing plays a crucial role in whether the bearing can operate normally. If the axial clearance is too small, it will lead to a relatively high temperature rise; if the axial clearance is large, the bearing is prone to damage. Therefore, when installing and operating the bearing, it is necessary to pay attention to adjusting the axial clearance, and if necessary, pre - install with interference to increase the rigidity of the bearing. So, how should an insert ball bearing be installed?

Installation Method of Insert Ball Bearings

1. Before installation, be sure to first pull out the fixing pin of the outer bearing sleeve. At the same time, polish the journal surface to make it smooth and clean, free from dust, etc., and apply oil on the journal for rust prevention and lubrication (allowing the bearing to rotate slightly on the shaft).

2. Apply lubricating oil to the mating surface between the bearing housing and the bearing, then install the bearing into the bearing housing. Next, put the assembled bearing and the bearing housing onto the shaft and push them to the installation position for installation.

3. Do not tighten the bolts fixing the bearing housing first. Let the outer bearing sleeve rotate freely in the bearing housing. Similarly, install the bearing and the housing at the other end of the same shaft. Rotate the shaft several times to let the bearing self - align automatically, and then tighten the bearing housing bolts.

4. Install the eccentric sleeve. First, put the eccentric sleeve on the eccentric step of the inner bearing sleeve and tighten it by hand in the direction of the shaft's rotation. Then insert a small iron rod into or against the counterbore on the eccentric sleeve. Use a hammer to strike the small iron rod in the direction of the shaft's rotation to install the eccentric sleeve firmly. Finally, lock the hexagon socket head cap screw on the eccentric sleeve.

This is the installation method of insert ball bearings. Then, how should they be disassembled during fault repair or regular maintenance?

Disassembly Method of Insert Ball Bearings

1. First, use an inner hexagon wrench to loosen the locking screw on the eccentric sleeve of the bearing. Then insert a small iron rod into the counterbore on the eccentric sleeve of the top cover and loosen the eccentric sleeve in the opposite direction of the shaft's rotation.

2. Loosen the bolts fixing the bearing housing. Remove the bearing together with the bearing housing from the shaft. Note that before removing the bearing housing at one end of the shaft, the bolts of the bearing housing at the other end of the shaft should be loosened to avoid damage caused by the jamming of the two - end bearings.

Since insert ball bearings are often used in machinery such as agricultural, transportation, or construction systems, one of their main features is double - layer sealing. This can effectively prevent dust and other impurities from entering the interior during outdoor operations, protecting the bearing's operating environment. In recent years, there have also been three - layer - sealed insert ball bearing products on the market, which have a better dust - proof effect than double - layer - sealed products and can more effectively extend the service life of the bearing.

By implementing these measures, the risk of bearing ring cracking can be effectively reduced, extending the bearing's service life.