Newsroom

What to Consider When Using Combined Bearings?

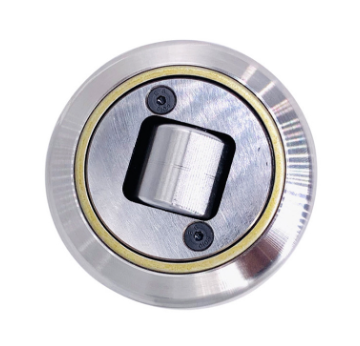

2024-12-20Combined bearings are bearings made from different materials, typically consisting of metals, plastics, or solid lubricants. These bearings provide excellent friction and lubrication performance in sliding, rotating, oscillating, or reciprocating motions.

Combined bearings are sliding bearings, usually cylindrical in shape, without moving parts. They typically feature a metal backing (often steel or copper) with a sintered porous copper intermediate layer, which is impregnated with PTFE and additives to create a low-friction and high-wear-resistant bearing surface. Additionally, combined bearings can also be made from engineering plastics, offering excellent wear resistance and low friction properties.

Points to Consider When Using Composite Bearings:

1.Prevent Corrosion

Combined bearings are typically made up of two or more layers of different metals, so special attention must be given to prevent corrosion during use. It is recommended to use mineral oil to protect the bearing’s outer material, especially when handling the bearings directly with hands.

2.Maintain Cleanliness

When installing and using combined bearings, ensure that the bearing and its surrounding environment are clean. Even small particles of dust entering the bearing can cause increased wear, vibration, and noise.

3.Use Appropriate Tools

When using combined bearings, ensure that proper and precise installation tools are employed. Avoid using excessive force, such as stamping or hammering directly onto the bearing, as this can lead to bearing damage.

4.Maintain a Dry and Clean Environment

Keep the composite bearings in a dry and clean working environment. Avoid contact with water and certain chemical corrosives to prevent damage to the bearings.

5.Regular Inspection and Maintenance

To ensure the safe and stable operation of equipment, regularly inspect and maintain the combined bearings. Timely detection and resolution of potential issues will help ensure a longer service life for the bearings.

For more information, feel free to contact QIBR