Newsroom

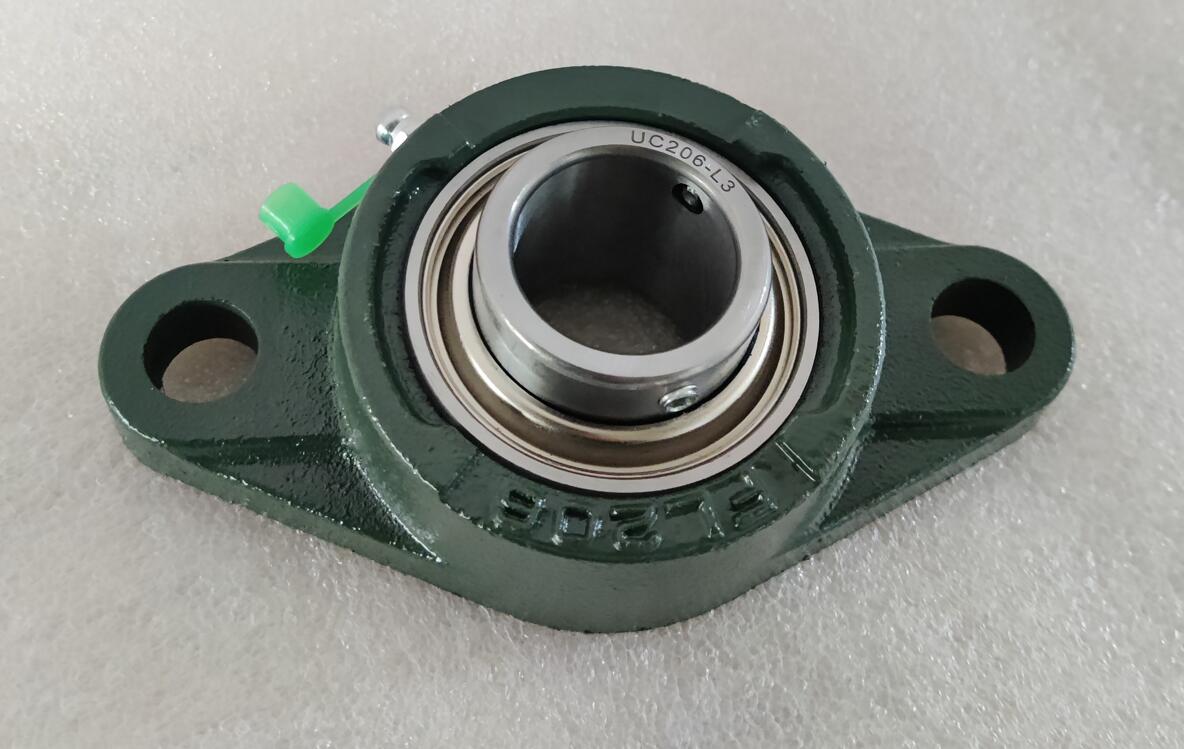

Which material is better for bearing housings? Cast iron or cast steel

2018-09-05The choice of material for bearing housings (cast iron or cast steel) should be based on specific application requirements and working conditions. Below is a detailed comparison and analysis of their applicable scenarios:

1. Cast Iron Bearing Housing

Advantages:

- Lower Cost: Cast iron is relatively inexpensive, making it suitable for projects with limited budgets.

- High Hardness: Cast iron has high hardness and good wear resistance, making it suitable for low-speed and light-load applications.

- Good Vibration Damping: Cast iron has excellent vibration damping properties, effectively absorbing vibrations, making it suitable for applications requiring reduced vibrations.

- Ease of Machining: The brittleness of cast iron makes it easier to process during cutting operations (e.g., threading).

Disadvantages:

- Poor Toughness: Cast iron is brittle and has low impact resistance, making it prone to cracking under shock loads.

- Unsuitable for Heavy Loads and High Speeds: In heavy-load or high-speed applications, cast iron's strength and toughness are insufficient, potentially leading to failure.

Applicable Scenarios:

- Low-speed, light-load mechanical equipment.

- Cost-sensitive applications where high-precision operation is not required.

- Applications requiring good vibration damping performance.

2. Cast Steel Bearing Housing

Advantages:

- High Strength: Cast steel has significantly higher strength than cast iron, enabling it to withstand greater loads.

- Good Toughness: Cast steel has excellent ductility and impact resistance, making it suitable for heavy-load and high-speed applications.

- Good Fatigue Resistance: Cast steel is less prone to fatigue cracks under repeated loads, making it suitable for long-term high-load operations.

Disadvantages:

- Higher Cost: Cast steel materials are more expensive, and machining is more challenging.

- Lower Hardness: Compared to cast iron, cast steel has lower hardness and slightly inferior wear resistance.

- Difficult Machining: Machining cast steel produces longer chips, which may increase tool wear.

Applicable Scenarios:

- Heavy-load, high-speed mechanical equipment.

- Applications requiring high strength and toughness.

- Equipment operating under long-term high loads.

3. Other Considerations

- Working Environment: If the working environment is harsh (e.g., high temperature, corrosive media), stainless steel or other special materials may be required.

- Service Life: For applications requiring long life and high reliability, cast steel is usually the better choice.

- Precision Requirements: For high-precision equipment, the stability and strength of cast steel better meet the requirements.

So cast iron bearing housings are a better choice for low-speed and light Load scenes, and cast steel bearing housings are better for heavy load and high speed. For special environments, you can consider special materials such as stainless steel or plastic based on specific needs.

The final choice should comprehensively consider factors such as equipment load, speed, working environment, service life, and cost to ensure that the bearing housing meets practical application requirements and has a long service life.

For more info, feel free to consider QIBR.