Newsroom

Why do bearing rings crack?

2025-02-24The reasons for deep groove ball bearing ring cracking are typically related to factors such as material, manufacturing process, operating environment, and lubrication conditions. Here are some common causes and explanations:

1.Contact Fatigue:

When deep groove ball bearings are subjected to repeated loads during operation, contact fatigue occurs. This fatigue leads to surface peeling of the material, which eventually results in cracks. These cracks initially appear as small, microscopic fissures that gradually expand over time, ultimately causing the bearing ring to break. The causes of contact fatigue primarily include the material's microstructure, surface hardening process, surface roughness, poor lubrication, and excessive stress.

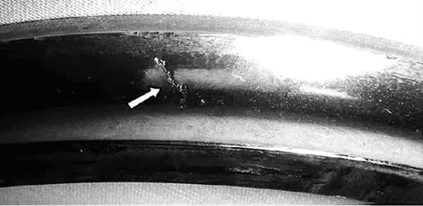

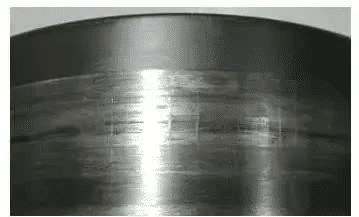

2.Grinding Cracks:

For both the outer and inner rings of deep groove ball bearings, excessive grinding, improper grinding conditions, or too much grinding material can lead to grinding cracks. These cracks usually appear as parallel cracks, commonly found on the raceway surface and aligned with the grinding direction. If the bearing outer ring is inadequately tempered, it increases its susceptibility to grinding cracks. These cracks can cause brittle fractures in local areas, ultimately forming macro-cracks.

3.Heat Treatment Issues:

If the deep groove ball bearing undergoes insufficient tempering during heat treatment, or if excessive heat is generated during grinding, the likelihood of cracks increases. If the outer and inner rings of the bearing are not properly heat-treated, cracks may form due to local stress concentrations.

4.Material Quality Problems:

The quality of the material used in deep groove ball bearings directly affects their fatigue resistance. If the material contains impurities, has uneven microstructure, or has too high a hardness with increased brittleness, cracks are more likely to occur. The material's brittleness can cause cracks due to stress concentrations during operation, which may then propagate inward.

5.Insufficient Lubrication:

If lubrication is inadequate, the friction during operation increases, leading to higher temperatures and surface damage, which further accelerates crack formation. Proper lubrication helps reduce friction and wear, extending the bearing's lifespan and preventing cracks.

6.Design Defects:

The design and manufacturing processes of deep groove ball bearings can also contribute to crack formation. If there are design flaws in the bearing ring, such as uneven contact between the inner and outer rings or improper fits, it can cause stress concentrations during operation, leading to cracks.

In conclusion, the cracking of bearing rings is primarily caused by material fatigue, improper grinding processes, insufficient heat treatment, poor lubrication, and design defects. To prevent such issues, the manufacturing process must strictly control material quality, optimize grinding processes, ensure proper heat treatment, and use appropriate lubrication.

For more information, feel free to contact QIBR