QJ218

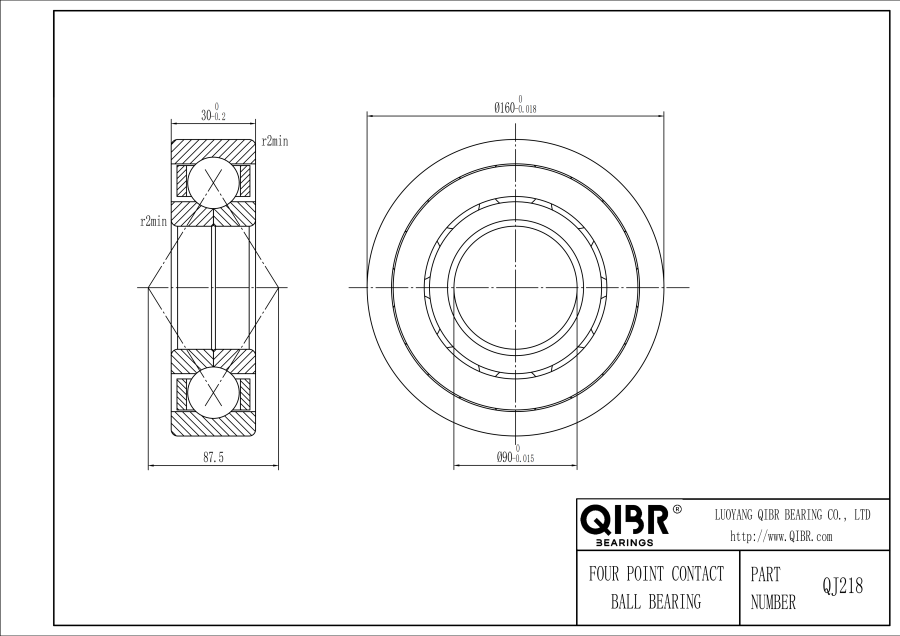

- Inner diameter:

- 90 mm

- Outer diameter:

- 160 mm

- Width:

- 30 mm

- Mass:

- 2.75 kg

We will provide you with the most suitable solution.

Image may differ from product. See technical specification for details.

Specifications

Seris - QJ218

Description

QIBR - QJ218 Angular Contact Ball Bearing Advantages and Applications

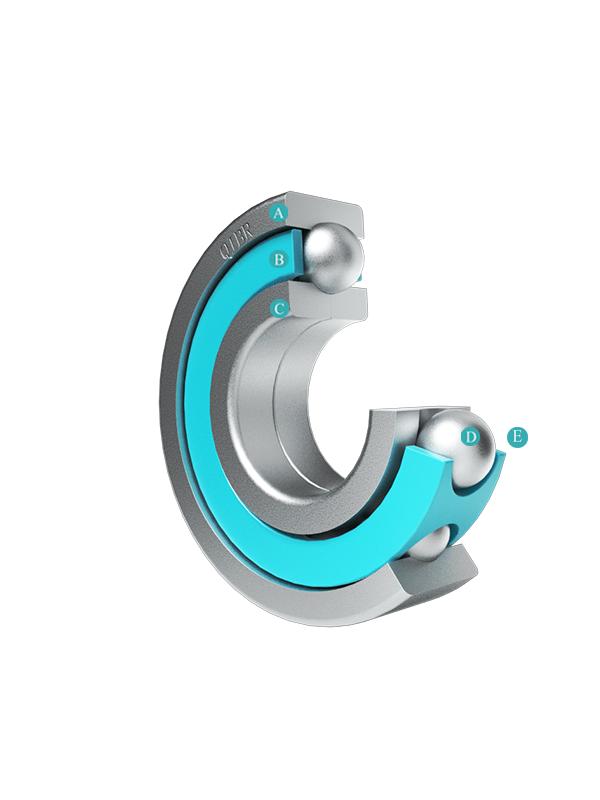

QJ218 Angular Contact Ball Bearing, contact angle design, high load-bearing capacity, Inner diameter (d) is 90 mm,Outer diameter (D) is 160 mm,Width (B) is 30 mm,Mass is 2.75 kg, suitable for machine tool spindles, high-frequency motors, gas turbines and centrifugal separators, etc., and is the most widely used bearing in working conditions with high load-bearing capacity requirements.

QIBR - QJ218 Angular Contact Ball Bearing Characteristics

QJ218 Angular Contact Ball Bearing, long service life, high cost performance. QJ218 Angular Contact Ball Bearing, can bear radial load and certain axial load at the same time, suitable for mechanical equipment with high load requirements.

QJ218 Angular Contact Ball Bearing Product Features and Advantages

High load capacity: It can withstand large radial and axial forces, and adopts high-strength steel and precision processing technology, with strong load-bearing capacity.

Good structural rigidity: The contact angle of the inner and outer rings is large, the structural rigidity is good, and stable operation is maintained under high load.

High positioning accuracy: The inner and outer rings have high matching accuracy, which can provide accurate positioning and centering functions.

High-speed operation performance: It has a low friction coefficient and high speed capability, suitable for high-speed operation applications.

Application: It has a wide range of applications in machine tool manufacturing, automotive industry, aerospace, motors and generators, robotics, medical equipment, automation equipment and other fields.

QIBR - QJ218 Angular Contact Ball Bearing Optimization

Optional Contact Angles: Depending on the operating conditions, different contact angles can be selected, such as 15°, 18°, 25°, or 40°.

High-Performance Materials: The bearing materials can be replaced according to different operating conditions, with options like SKF III, ZGcr15, high-purity bearing steel, ceramics, stainless steel, and other materials.

Grease Replacement: Select the lubrication based on the bearing's working requirements, such as LUBCON L252, Multemp SRL, or KLUBER ISOFLEX NBU 15.

Process parameter optimization: Optimize the processing parameters, such as grinding speed, feed speed, cutting depth, etc. to improve processing efficiency and quality.

More customization: QIBR can design and optimize the bearing according to customer requirements for drawings and bearing working conditions.

QIBR - QJ218 Angular contact ball bearing quality control

Dimension measurement: Use a variety of professional high-precision instruments to measure multiple dimensions of the bearing, with a maximum accuracy of 0.001mm.

Rotation accuracy: Use a micrometer to measure small flaws or deviations on the bearing surface, with a measurement accuracy of up to 0.001mm.

Hardness measurement: Use a hardness tester to measure the surface hardness of the bearing, with a measurement accuracy of up to ±0.5HRC.

Metallographic analysis: Use a professional metallographic microscope to analyze the internal metallographic structure of the metal.

Geometric tolerance: Use a profiler to measure the bearing geometry and relative position.

Noise monitoring: Vibration during operation is monitored by a vibration meter to obtain noise data.

Raw material control: Steel and parts are purchased from suppliers certified by ISO 14001 to ensure product stability and promote sustainable development.

Process And PerformanceContent

QIBR - QJ218 Angular Contact Ball Bearings Process and Performance Indicators:

-

Structural Features: The rings are made of high-purity bearing steel through electro-slag remelting, combined with bainite quenching heat treatment, cryogenic treatment, and material modification technology to reduce residual austenite, significantly improving the fatigue life of this series of bearings.

-

Contact Angle Control: The grinding wheel angle is calibrated using a laser alignment tool, with a tolerance of ≤±1′.

-

Surface Quality: After superfinishing, the surface roughness is Ra ≤ 0.005 μm, meeting (ABEC 7) P2 grade precision requirements.

-

High-Speed Performance: DLC-coated bearings support a dn value ≥ 3.5×10⁶, with a maximum speed of 25,000 rpm (grease lubrication).

-

Cleanliness: Assembly is conducted in an ISO Class 5 cleanroom using fully synthetic aviation grease.

-

Finished Product Sampling Inspection:

- Zeiss PRISMO Ultra (Germany) for full-size 3D coordinate measurement, supporting spatial accuracy of 0.5+L/350 μm.

- Contact angle (α) verification with ±0.5′ precision.

- Bearing vibration tester ensures low noise and high-speed performance (Z4/V4 grade standards).

-

Auxiliary Systems and Process Equipment: Vacuum carburizing with carburizing layer uniformity ≤ ±0.03 mm, enhancing bearing fatigue life.

QIBR - QJ218 Angular Contact Ball Bearings can be applied in the following R&D projects:

- Ultra-high-speed ball bearings (inner diameter >6 mm, outer diameter <360 mm, speed factor <4 million).

- High-temperature high-speed bearings (inner diameter >6 mm, outer diameter <200 mm, operating temperature <470°C, speed factor <4 million).

- Thin-walled ball bearings (width >3.969 mm, outer diameter <300 mm).

- Special high-temperature, low-temperature, and impact-resistant angular contact ball bearings for aviation engine spindle systems.

- Ultra-clean bearings for dust-free workshop environments.

- High-rigidity, low-noise bearings to improve joint motion accuracy.

- Special bearings with functional coatings.

- Special bearings for difficult-to-machine materials.

As a rolling bearing manufacturer, we specialize in producing ABEC 7 P4 and ABEC 9 P2 precision bearings designed for high-speed and heavy-load applications. We are happy to provide the best solutions using our expertise.

What do the prefix letters of angular contact ball bearings mean?

The prefix letters for angular contact ball bearings vary by brand. For example:

-

Sweden SKF QJ218:

- C = hybrid ceramic ball bearings,

- S = sealed bearings,

- SC = sealed with slopes on both inner and outer rings.

-

Germany FAG QJ218:

- B = standard,

- HCB = standard ceramic balls,

- XCB = ultra-long-life standard ceramic balls,

- RS = high-speed bearing steel balls,

- HCRS = high-speed bearing ceramic balls,

- HS = small ball bearing steel balls,

- HSS = small ball bearing steel balls with seals,

- HC = small ball bearing ceramic balls,

- HCS = small ball bearing ceramic balls with seals,

- XC = ultra-long-life small ceramic balls,

- XCS = ultra-long-life small ceramic balls with seals.

What do the suffix letters for contact angle mean in angular contact ball bearings?

The suffix letters for contact angle vary by brand. For example:

- Sweden SKF QJ218:

- CD = standard 15° contact angle,

- ACD = standard 25° contact angle,

- CE = high-speed 15° contact angle,

- FE = high-speed 18° contact angle,

- ACE = high-speed 25° contact angle,

- CB = B-structure 15° contact angle,

- FB = B-structure 18° contact angle,

- ACB = B-structure 25° contact angle.

- Germany FAG QJ218:

- C = 15° contact angle,

- D = 20° contact angle,

- E = 25° contact angle.

- Japan NSK QJ218:

- C = 15° contact angle,

- A5 = 25° contact angle,

- A = 30° contact angle.

What do the suffix letters for preload mean in angular contact ball bearings?

The suffix letters for preload vary by brand. For example:

- Sweden SKF QJ218:

- GA = universal single light preload,

- GB = universal single medium preload,

- GC = universal single heavy preload,

- GD = universal single extra-heavy preload.

- Germany FAG QJ218:

- L = light preload,

- M = medium preload,

- H = heavy preload.

- Japan NSK QJ218:

- L = light preload,

- M = medium preload,

- H = heavy preload.

What do the suffix letters for cage type mean in angular contact ball bearings?

The suffix letters for cage type vary by brand. For example:

- Sweden SKF QJ218:

- Default = phenolic resin,

- MA = brass,

- TNHA = PEEK.

- Japan NSK QJ218:

- TYN = nylon,

- TR = phenolic resin.

What do the suffix letters for rolling elements mean in angular contact ball bearings?

The suffix letters for rolling elements vary by brand. For example:

- Sweden SKF QJ218:

- HC = ceramic balls,

- Default = steel balls.

- Japan NSK QJ218:

- SN24 = ceramic balls.

What do the suffix letters for precision grade mean in angular contact ball bearings?

The suffix letters for precision grade vary by brand. For example:

- Sweden SKF QJ218: P4, P4A, P2, PA9A.

- Germany FAG QJ218: P5, P5S, P4, P4S, P2.

- Japan NSK QJ218: P2, P4, P5.

What do the suffix letters for bearing set quantity mean in angular contact ball bearings?

The suffix letters for bearing set quantity vary by brand. For example:

- Sweden SKF QJ218:

- D = two bearings,

- T = three bearings,

- Q = four bearings,

- P = five bearings.

The suffix letters for pairing method in angular contact ball bearings

The suffix letters for pairing method vary by brand. For example:

- Sweden SKF QJ218:

- B = back-to-back,

- F = face-to-face,

- T = tandem,

- BT = back-to-back tandem,

- FT = face-to-face tandem,

- BC = back-to-back paired,

- FC = face-to-face paired.

- Germany FAG QJ218:

- U = universal single,

- DU = two universal singles,

- DB = back-to-back,

- DT = tandem,

- DF = face-to-face,

- TU = three universal singles,

- TBT = triple matched,

- TT = triple matched,

- TFT = triple matched,

- QBC = quadruple matched,

- QFC = quadruple matched,

- QT = quadruple matched,

- QBT = quadruple matched,

- QFT = quadruple matched,

- PBC = quintuple matched,

- PFC = quintuple matched,

- PT = quintuple matched,

- PBT = quintuple matched,

- PFT = quintuple matched.

- Japan NSK QJ218:

- SU = universal single,

- DU = two universal singles,

- DB = back-to-back,

- DF = face-to-face,

- DT = tandem,

- DBD = triple matched,

- DFD = triple matched,

- DTD = triple matched,

- DBB = quadruple matched,

- DFF = quadruple matched,

- DBT = quadruple matched,

- DFT = quadruple matched,

- DTT = quadruple matched.

The suffix letters for bearing type in angular contact ball bearings

The suffix letters for bearing type vary by brand. For example:

- Germany FAG QJ218:

- T = phenolic resin outer ring guided,

- DLR = annular groove with drilled holes and O-ring,

- 2RSD = double-sided seals.

Features & Benefits

Angular contact ball bearings are more suitable for high-speed running occasions, they could carry both radial load and axial load. the axial load carrying capacity is related to the contact angle. The larger the contact angle, the greater the axial load that can be carried. The limiting speed of angular contact ball bearings is higher than other types of bearings of the same size. They are usually used in pairs, because they bear the effect of radial load and also produce axial force components. When working, the angular contact ball bearing can eliminate the internal clearance of the angular contact ball bearing due to the axial load after installation, which also relatively improves the rotation accuracy of the angular contact ball bearing.

Downloads