6203 2rs

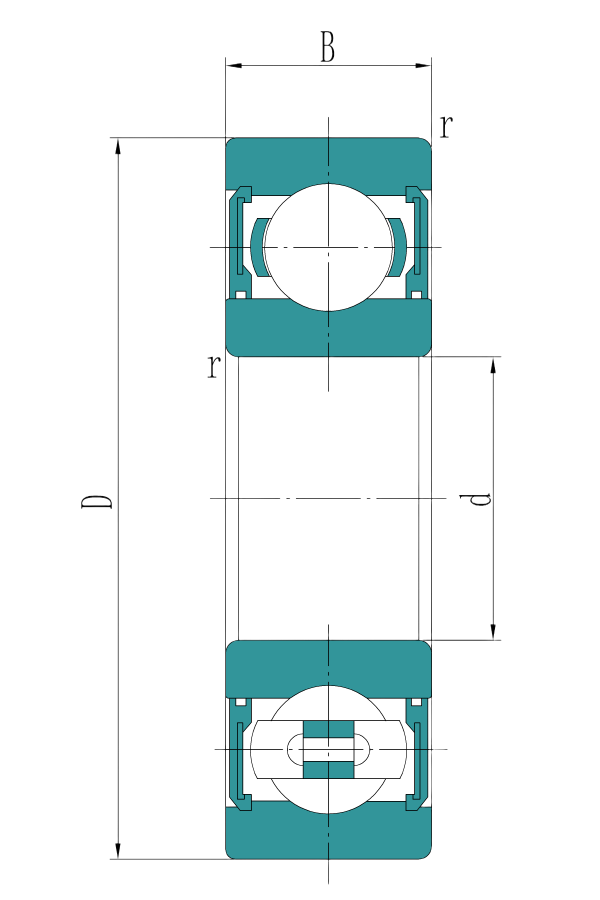

- Inner diameter:

- 17 mm

- Outer diameter:

- 50 mm

- Width:

- 18 mm

We will provide you with the most suitable solution.

Image may differ from product. See technical specification for details.

Specifications

Seris - 6203 2rs

Description

QIBR - 6203 2rs Coated Bearing Advantages and Applications

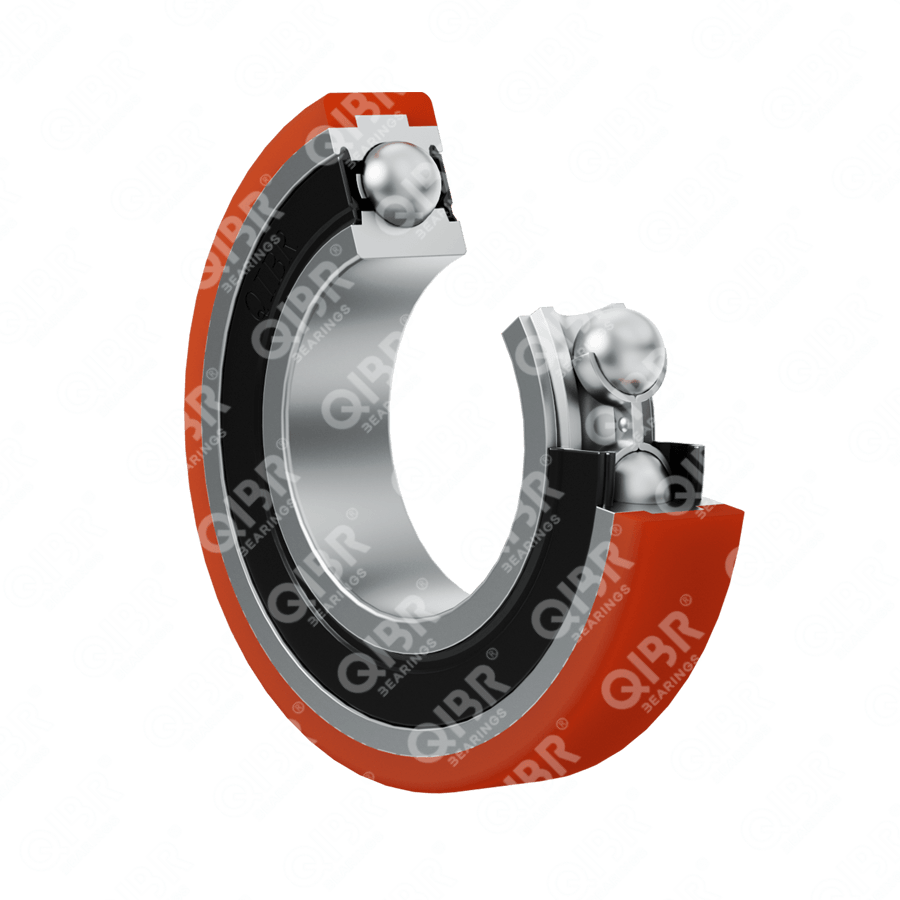

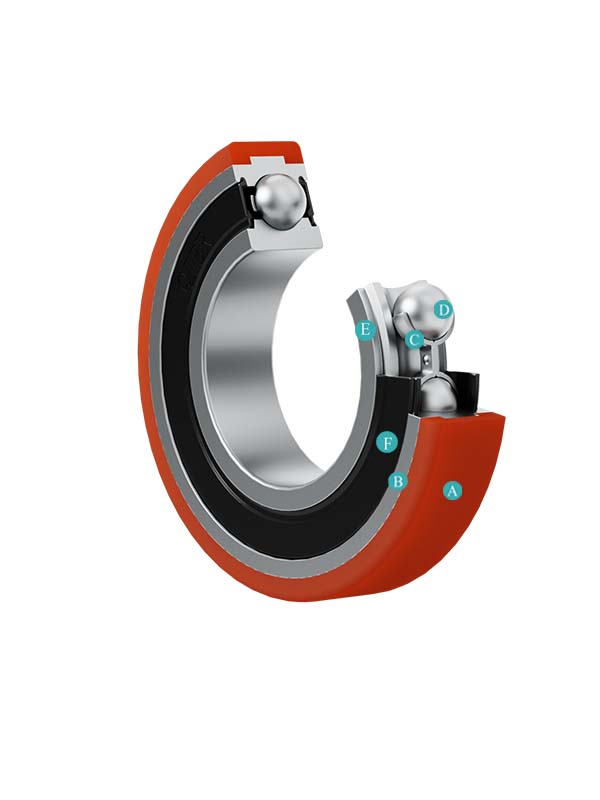

6203 2rs Coated Bearing, strong noise reduction capability, strong wear resistance, Bore is 17 mm, Outer diameter (D) is 50 mm, Width is 18 mm, suitable for electric sanding machines, air conditioners, wheel bearings and roller conveyor systems, etc., and is the most widely used bearing in conditions requiring high precision.

QIBR - 6203 2rs Coated Bearing Characteristics

6203 2rs Coated Bearing, long life, high cost performance. 6203 2rs Coated Bearing, can bear radial load and small axial load, suitable for mechanical equipment with high life requirements.

6203 2rs Rubber Coated Bearings Features and Advantages

Protection: Rubber Coated Bearings offer robust protection against dust, moisture, and other contaminants, significantly extending the bearing's lifespan.

High Adaptability: These bearings are designed to withstand high temperatures, humidity, and chemical corrosion, ensuring reliable performance in various conditions.

Low Vibration and Noise: The rubber encapsulation effectively reduces operating noise, providing excellent elasticity and shock absorption, which helps to absorb mechanical vibrations and impact loads, reducing vibration transmission during operation.

Application: Rubber Coated Bearings are widely used in automotive, household appliances, industrial machinery, medical devices, agricultural machinery, construction equipment, and sports equipment.

QIBR - 6203 2rs Rubber Coated Bearings Optimization

Design Optimization: Custom geometric design optimization is performed based on customer requirements to reduce friction and wear, thereby improving operational efficiency.

Encapsulation Material: The material for encapsulation is selected based on the working conditions and customer requirements, such as PEEK, nylon, POM, polyurethane, etc.

Lubricant Replacement: Lubricants are selected according to the operational needs of the bearing, for example, SKF LGWA 2, Mobilux EP 004, Great Wall 7014-1, etc.

Further Customization: QIBR offers bearing design and optimization according to customer drawings and specific operational requirements.

QIBR - 6203 2rs Rubber Coated Bearings Quality Control

Dimension measurement: Multiple high-precision instruments are used to measure various dimensions of the bearing, with precision up to 0.001mm.

Rotation accuracy: Dial gauges are used to measure small defects or deviations on the bearing surface, with precision up to 0.001mm.

Hardness measurement: The surface hardness of the bearing is measured using a hardness tester, with precision up to ±0.5 HRC.

Metallographic analysis: A professional metallographic microscope is used to analyze the internal metallographic structure of the metal.

Axial Clearance: A specialized universal bearing axial clearance measuring tool is used to measure the bearing clearance.

Noise monitoring: Vibration meters are used to monitor vibration during operation, providing noise data.

Raw material control: Steel and components are sourced from suppliers certified with ISO 14001, ensuring product stability while promoting sustainable development.

Features & Benefits

Bearing encapsulation is a common bearing sealing method, which has good sealing performance and protection. It can protect the bearing from pollution and damage, extend the life of the bearing, especially in high-speed work and harsh environment use, more can play its advantages.

Downloads