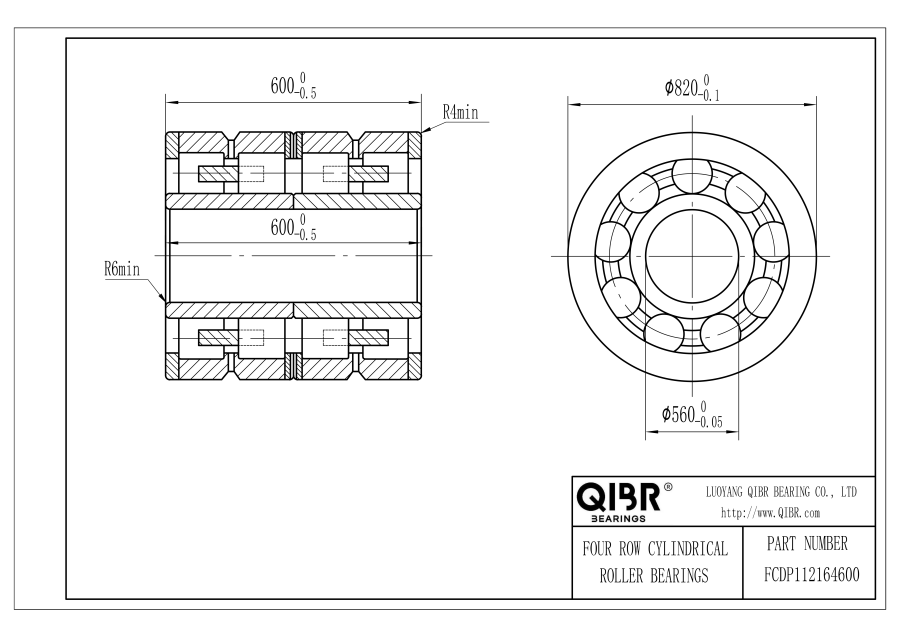

FCDP112164600

- Inner diameter:

- 560 mm

- Outer diameter:

- 820 mm

- Width:

- 300 mm

- Mass:

- 1071 Kg

We will provide you with the most suitable solution.

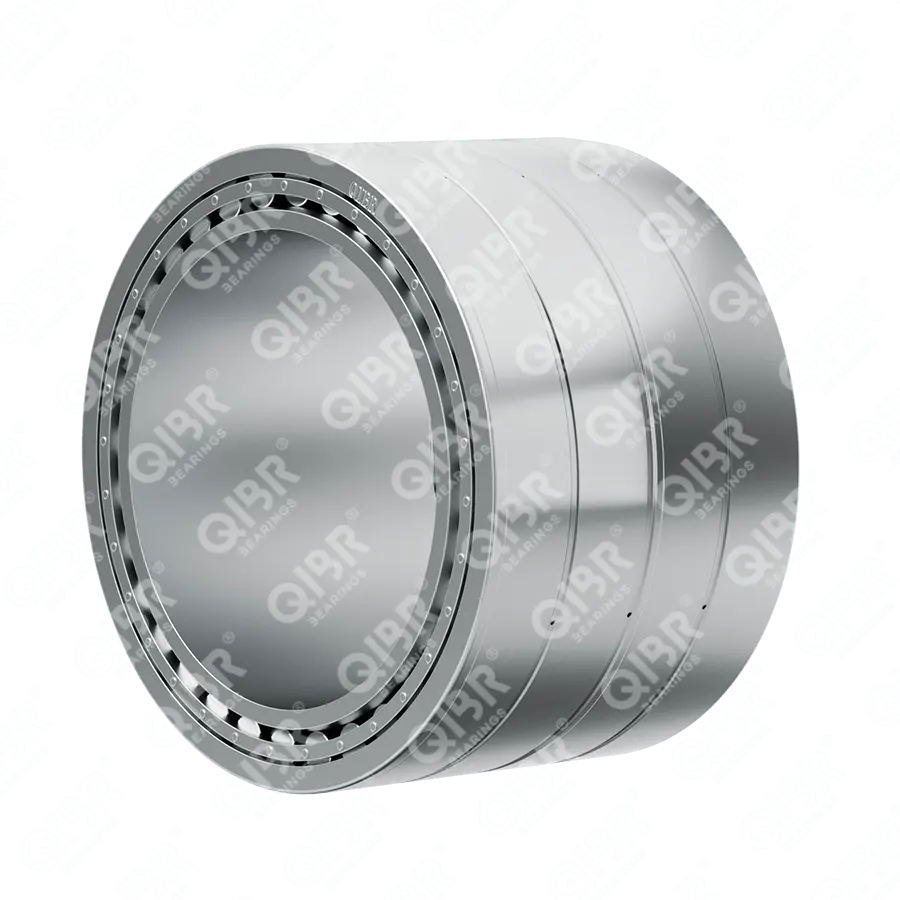

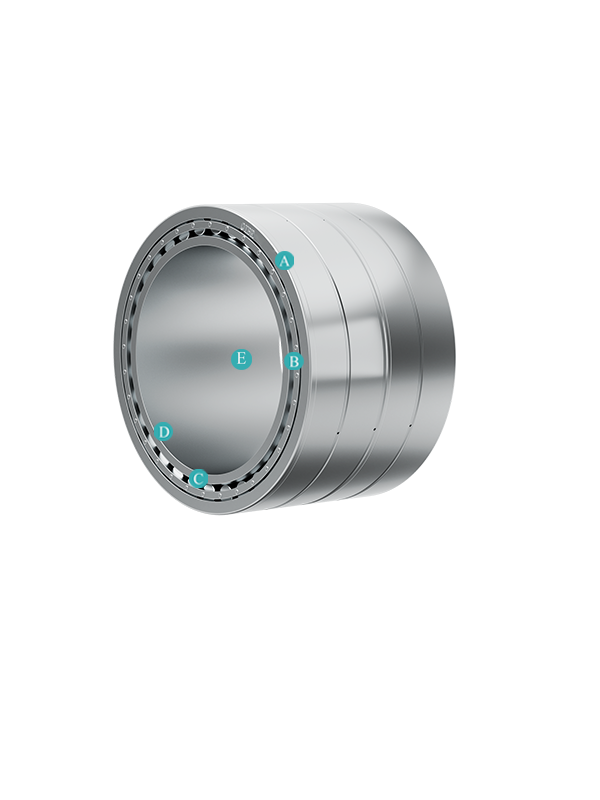

Image may differ from product. See technical specification for details.

Specifications

Seris - FCDP112164600

Description

QIBR - FCDP112164600 Cylindrical Roller Bearing Advantages and Applications

FCDP112164600 Cylindrical Roller Bearing, strong wear resistance, high stability, Inner diameter (d) is 560 mm,Outer diameter (D) is 820 mm,Width (B2) is 300 mm,Width (d4) is 600 mm,Mass is 1071 kg, suitable for papermaking machines, vibrating screens, lifting and transportation machinery and internal combustion engines, etc., and is the most widely used bearing in working conditions with high performance requirements.

QIBR - FCDP112164600 Cylindrical Roller Bearing Characteristics

FCDP112164600 Cylindrical Roller Bearing, simple maintenance and easy installation. FCDP112164600 Cylindrical Roller Bearing, can bear radial load and certain axial load at the same time, suitable for mechanical equipment with high stability requirements.

FCDP112164600 Cylindrical Roller Bearing Features and Advantages

High load capacity: Designed with a high radial load capacity, suitable for heavy loads and shock loads, making it ideal for high-load conditions.

Low Friction Coefficient: The line contact between the rollers and raceways results in a low friction coefficient, making it suitable for high-speed operation.

Separable Design: The inner and outer rings can be separated, facilitating easy installation and disassembly, ideal for equipment requiring frequent maintenance.

High Adaptability: Capable of accommodating changes in relative position due to thermal expansion or installation errors, suitable as a free-end bearing.

Application: Extensively used in the automotive industry, industrial machinery, motors and power generation equipment, household appliances, aerospace, medical equipment, railways and transportation, construction machinery, wind energy, and renewable resources.

QIBR - FCDP112164600 Cylindrical Roller Bearing Optimization

Selectable Precision, Vibration, and Noise Levels: Options include P6, P5 for precision, V2, V3 for vibration, and Z2, Z3 for noise.

Cage Material: The cage material can be chosen based on operating conditions, with options including steel, brass, or nylon.

Grease Replacement: Select lubrication according to bearing working requirements, such as SKF LGMT 2, Timken GR217, or Shell Gadus S2 V220AC.

Optimized Roller Profile: Depending on operating conditions, logarithmic profile curves can be used to optimize the roller profile, reducing stress concentration between rollers and raceways, and enhancing load capacity and service life.

More customization: QIBR can design and optimize bearings according to customer drawings and operating conditions.

QIBR - FCDP112164600 Cylindrical Roller Bearing Quality Control

Dimension measurement: Various high-precision instruments are used to measure multiple dimensions of the bearing, with an accuracy of up to 0.001mm.

Rotation accuracy: A dial gauge measures minor surface flaws or deviations, with measurement accuracy reaching 0.001mm.

Hardness measurement: Surface hardness is measured using a hardness tester, with an accuracy of ±0.5HRC.

Metallographic analysis: Internal metallographic structure is analyzed using a professional metallographic microscope.

Geometric tolerance: A contour gauge measures the bearing's geometric shape and relative position.

Noise monitoring: A vibration meter monitors vibration during operation to obtain noise data.

Raw material control: Steel and parts are sourced from ISO 14001-certified suppliers, ensuring product stability while promoting sustainable development.

Features & Benefits

Cylindrical roller bearings are widely used in various industries including the automotive sector, machine tool manufacturing, power generation, construction machinery, heavy equipment manufacturing, wind power generation, and aerospace, etc.

Downloads