6201 2Z

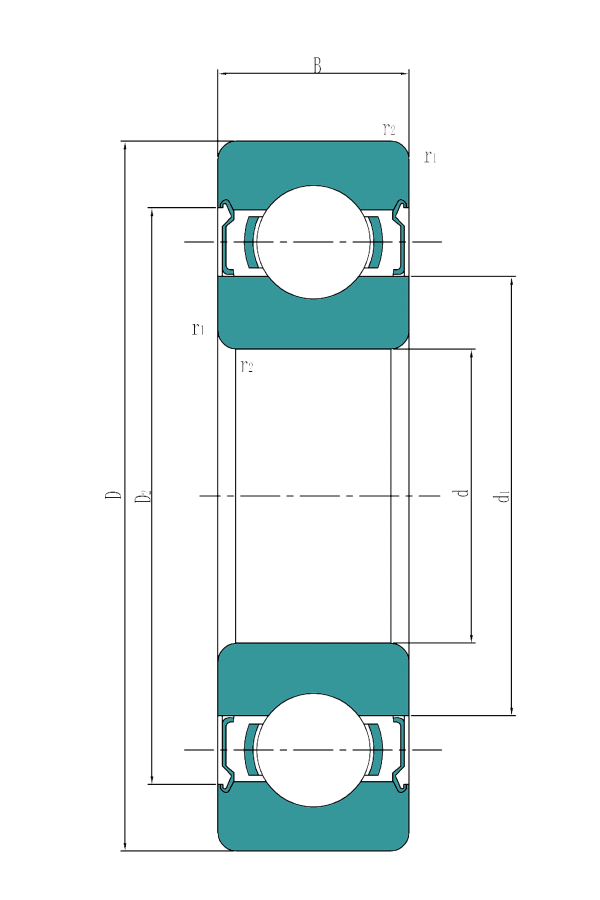

- Inner diameter:

- 12 mm

- Outer diameter:

- 32 mm

- Width:

- 10 mm

- Mass:

- 36 g

We will provide you with the most suitable solution.

Image may differ from product. See technical specification for details.

Specifications

Seris - 6201 2Z

Description

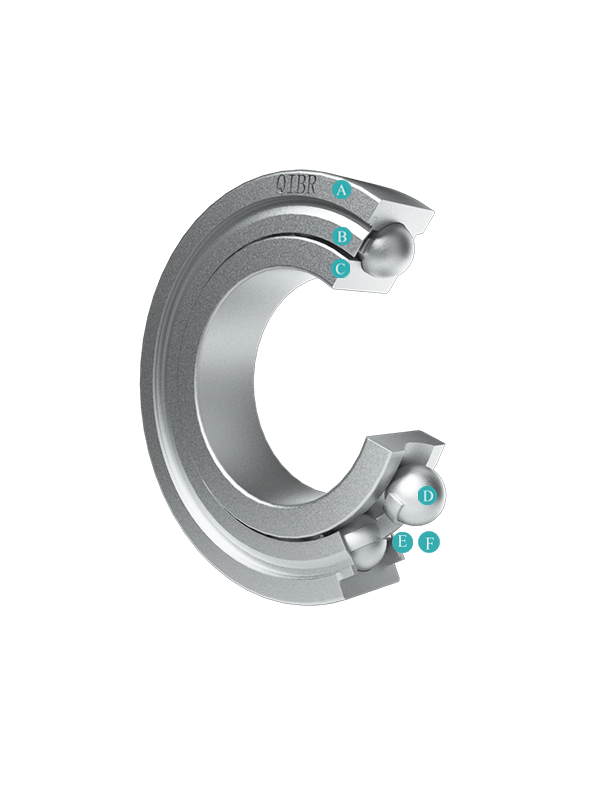

QIBR - 6201 2Z Deep Groove Ball Bearing Advantages and Applications

6201 2Z Deep Groove Ball Bearing, high quality performance, high speed, Inner diameter (d) is 12 mm,Outer diameter (D) is 32 mm,Width (B) is 10 mm,Mass is 36 g, suitable for cranes, gearboxes, spinning machines and generators, etc., and is the most widely used bearing in working conditions with high performance requirements.

QIBR - 6201 2Z Deep Groove Ball Bearing Characteristics

6201 2Z Deep Groove Ball Bearing, low manufacturing cost and long life. 6201 2Z Deep Groove Ball Bearing, can bear radial load and certain axial load at the same time, suitable for mechanical equipment with high stability requirements.

6201 2Z Deep Groove Ball Bearing Product Features and Advantages

High Load Capacity: Capable of simultaneously bearing large radial and axial loads, suitable for various load conditions.

Simple Structure: Low manufacturing cost, high cost-effectiveness, simple design, easy to manufacture and install.

Self-Aligning Ability: Possesses a certain degree of self-aligning capability, automatically adjusting the relative position of the inner and outer rings, reducing precision requirements during installation.

Smooth Operation: Low friction coefficient, resulting in low noise during operation, suitable for high-speed applications.

Application: Widely used in electric motors, automotive industry, household appliances, industrial machinery, agricultural machinery, wind turbines, railway vehicles, construction machinery, and more.

QIBR - 6201 2Z Deep Groove Ball Bearing Optimization

Optional Types: Can be supplied with CN or C3 group clearance, or customized clearance based on customer requirements.

Grease Replacement: Lubricants can be chosen based on bearing operational needs, such as SKF LGED 2, Mobil SHC Polyrex 102 EM, etc.

Cage Types: Cage type can be selected according to bearing operating conditions, such as two-piece riveted steel cage, one-piece stainless steel crown cage, one-piece polymer crown cage, machined brass cage, etc.

Further Customization: QIBR can design and optimize bearings according to customer drawings and operational requirements.

QIBR - 6201 2Z Deep Groove Ball Bearing Quality Control

Dimension measurement: Multiple high-precision instruments are used to measure various dimensions of the bearing, with an accuracy of up to 0.001mm.

Rotation accuracy: A dial gauge measures minor surface flaws or deviations, with measurement accuracy reaching 0.001mm.

Hardness measurement: The surface hardness of the bearing is measured using a hardness tester, with an accuracy of ±0.5HRC.

Metallographic analysis: A professional metallographic microscope is used to analyze the internal metallographic structure of the metal.

Geometric tolerance: A profilometer is used to measure the geometric shape and relative position of the bearing.

Noise monitoring: A vibration meter monitors vibrations during operation, providing noise data with a noise vibration level not lower than Z3V3.

Raw material control: Steel and parts are sourced from ISO 14001-certified suppliers, ensuring product stability while promoting sustainable development.

Process And PerformanceContent

QIBR - 6201 2Z Deep Groove Ball Bearing Manufacturing Process and Performance Indicators:

Material Processing: The rings and rolling elements can be customized according to customer requirements, using materials such as GCr15, 440C, Si₃N₄, M50, etc. Precision cold heading machines are employed for material processing, with an accuracy of ±0.008mm.

Machining Process: CNC turning centers are used for bearing turning, achieving a roundness of ≤1.5 μm. The bearings undergo surface quenching in a mesh belt-type furnace with a temperature control accuracy of ±1°C. Tempering is performed in a tempering furnace equipped with an atmosphere protection system, ensuring temperature uniformity of ±3°C. Finally, cryogenic treatment is conducted using program-controlled temperature equipment.

Surface Quality: After superfinishing, the surface roughness reaches Ra ≤ 0.005μm, with waviness ≤ 0.1μm, meeting (ABEC 7) P2-grade precision requirements. Mirror finishing achieves Ra ≤ 0.02μm.

Cleanliness: Assembly is carried out in an ISO Class 6 cleanroom. Fully synthetic aviation grease is used, with cleanliness ≤ 0.5mg/set, compliant with ISO 4406.

Finished Product Sampling Inspection:

- Zeiss PRISMO Ultra (Germany): Performs full-size 3D coordinate measurements with spatial accuracy ≤ 1.5μm for dimensional precision inspection.

- Microscopy: 1000X magnification is used to inspect carbide distribution and decarburization layers.

- Vibration Tester: Complies with ISO 15242 to measure Z1/Z2/Z3 group vibration values.

Auxiliary Systems & Process Equipment: Vacuum carburizing ensures carburizing layer uniformity ≤ ±0.03mm, enhancing bearing fatigue life.

QIBR 6201 2Z Deep Groove Ball Bearings – R&D Applications

High/Low-Temperature Bearings: Optimize heat treatment or develop new lubrication solutions for metallurgical equipment or aerospace extreme-temperature environments.

High-Speed Bearings: Improve cage structure to reduce centrifugal effects, meeting demands for electric spindles and turbomachinery.

High-Performance Materials: Develop special alloy or composite bearings to enhance high-temperature resistance, corrosion resistance, and fatigue performance.

Lightweight Design: Use aluminum-magnesium alloy or carbon fiber cages for weight-sensitive applications like aerospace and new energy vehicles.

Self-Lubricating Materials: Develop polymer cages with graphene or MoS₂ to reduce maintenance needs.

Special Bearings with Functional Coatings.

Special Bearings for Difficult-to-Machine Materials.

As a rolling bearing manufacturer, we specialize in producing ABEC 7 P4 and ABEC 9 P2 precision-grade bearings designed for high-speed and heavy-load applications. We are happy to leverage our expertise to provide the best solutions.

What Do the Prefix Letters and Numbers of Deep Groove Ball Bearings Mean?

The prefix letters and numerical codes for deep groove ball bearings vary across brands. For example, in Sweden's SKF 6201 2Z :

- D/W = Stainless steel, inch dimensions

- ICOS- = Oil-sealed bearing unit

- W = Stainless steel, metric dimensions

- WBB1 = Stainless steel, metric dimensions (non-ISO dimension series)

What Do the Prefix Letters for Deep Groove Ball Bearing Types Mean?

Different brands use different letters to represent bearing types. For example, in SKF 6201 2Z :

- 2.. = 02 series dimension, single-row bearing with filling slot

- 3.. = 03 series dimension, single-row bearing with filling slot

- EE, EEB, R, RLS, RMS = Inch-sized bearings

What Do the Internal Design Letters of Deep Groove Ball Bearings Mean?

Internal design codes differ by brand. For example, in SKF 6201 2Z :

- A, AA, C, D = Modified or slightly altered internal design

- E = Reinforced ball set

What Do the External Design Letters of Deep Groove Ball Bearings Mean?

External design markings vary by manufacturer. For example:

SKF 6201 2Z

- N = Outer ring with snap ring groove

- NR = Outer ring with snap ring groove and snap ring

- N1 = Outer ring with one locating groove (recess)

- R = Outer ring with flange

- -RS1, -2RS1 = One side or both sides with NBR (nitrile rubber) contact seals

- -RS2, -2RS2 = One side or both sides with FKM (fluoro rubber) contact seals

- -RSF, -2RSF = One side or both sides with NBR contact seals

- -RSH, -2RSH = One side or both sides with NBR contact seals

- -RSH2, -2RSH2 = One side or both sides with FKM contact seals

- -RSL, -2RSL = One side or both sides with low-friction NBR seals

- -RZ, -2RZ = One side or both sides with NBR non-contact seals

- -Z, -2Z = One side or both sides with metal shields

- -ZNBR = One side with a metal shield, an outer ring with snap ring groove, snap ring on the same side as the shield

- -ZNR = One side with metal shield, outer ring with snap ring groove, snap ring on the opposite side of the shield

- -2ZNR = Outer ring with snap ring groove and snap ring, both sides with metal shields

- -2ZS = Both sides with metal shields secured by a retaining ring

- X = Dimensions do not conform to ISO size series

Japan's NSK 6201 2Z

- ZZ = Both sides with metal shields

- DDU = Both sides with rubber contact seals

- W = Both sides with rubber non-contact seals

- Z = One side with metal shield

- DU = One side with rubber contact seal

- V = One side with rubber non-contact seal

What Do the Suffix Letters for Deep Groove Ball Bearing Cages Mean?

The suffix letters for bearing cages vary by brand. For example, in Sweden's SKF 6201 2Z:

- Stainless steel bearings: Stamped stainless steel cage, ball-guided

- Other bearings: Stamped steel cage, ball-guided

- JEM = Stamped steel cage, ball-guided

- M = Machined brass cage, ball-guided

- MA(S) = Machined brass cage, outer ring-guided ("S" indicates lubrication grooves on the guiding surface)

- MB(S) = Machined brass cage, inner ring-guided ("S" indicates lubrication grooves on the guiding surface)

- TN = PA66 cage, ball-guided

- TN9 = Glass fiber-reinforced PA66 cage, ball-guided

- TN9/VG1561 = Glass fiber-reinforced PA46 cage, ball-guided

- TNH = Glass fiber-reinforced PEEK cage, ball-guided

What Do the Suffix Letters for Bearing Materials and Heat Treatment Mean?

Material and heat treatment codes differ by brand. For example, in SKF 6201 2Z:

- HA1 = Surface-hardened inner and outer rings

- HC5 = Silicon nitride balls (hybrid ceramic bearings)

What Do the Suffix Letters for Precision, Cleanliness, Preload, and Quiet Operation Mean?

Precision and operational codes vary by manufacturer. For example:

SKF 6201 2Z

- P5 = Dimensional and geometric tolerances (runout and positioning) meet P5 grade

- P6 = Dimensional and geometric tolerances (runout) meet P6 grade

- P52 = P5 + C2

- P62 = P6 + C2

- P63 = P6 + C3

- CN = Normal radial clearance group

- C1 = Radial clearance smaller than C2

- C2 = Radial clearance smaller than normal group

- C3 = Radial clearance larger than normal group

- C4 = Radial clearance larger than C3

- C5 = Radial clearance larger than C4

- CA = Matched bearings with small axial clearance

- GA = Matched bearings with light preload

Japan's NSK 6201 2Z

- CN = Normal radial clearance group

- C2 = Radial clearance smaller than normal group

- C3 = Radial clearance larger than normal group

- C4 = Radial clearance larger than C3

- C5 = Radial clearance larger than C4

What Do the Suffix Letters for Bearing Pairing Mean?

Pairing configurations vary by brand. For example, in SKF 6201 2Z:

- DB = Back-to-back paired mounting

- DF = Face-to-face paired mounting

- DT = Tandem paired mounting

What Do the Suffix Letters for Dimensional Stability Mean?

Thermal stability codes differ by manufacturer. For example, in SKF 6201 2Z:

- S0 = Bearing rings maintain dimensional stability at operating temperatures ≤ 150°C (300°F)

- S1 = Bearing rings maintain dimensional stability at operating temperatures ≤ 200°C (390°F)

What Do the Suffix Letters for Bearing Grease Mean?

Grease types vary by brand. For example:

SKF 6201 2Z

- GE2 = Lithium soap

- GFJ = Complex aluminum soap

- GJN = (Specific grease type, not explicitly defined here)

- HT = Polyurea

- LHT23 = Lithium soap

- LT = Lithium soap

- MT33 = Lithium soap

- MT47 = Lithium soap

- VT378 = Complex aluminum soap

- WT = Polyurea

Japan's NSK 6201 2Z

- NS7 = NS HI-LUBE (specialty grease)

Features & Benefits

Deep groove ball bearing with low friction coefficient, high limit speed, various size ranges and forms, it is suitable for precision instruments, low-noise motors, automobiles, motorcycles and general machinery. It is the most widely used in the machinery industry.

Downloads