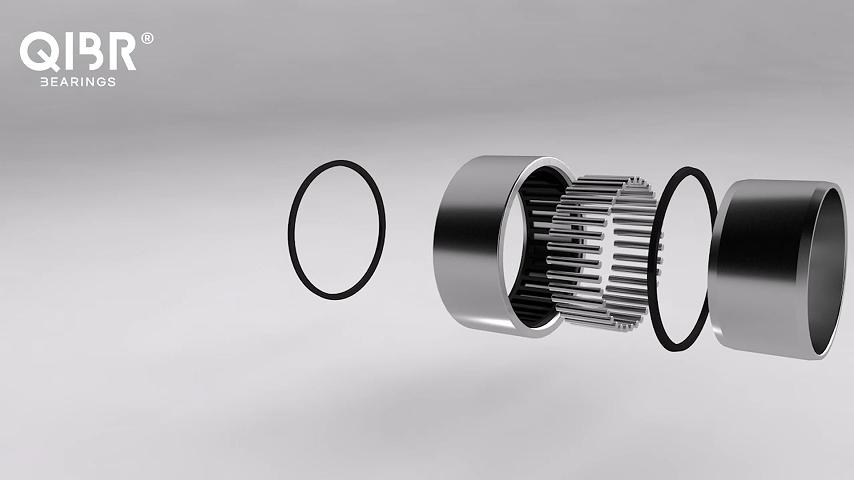

Image may differ from product. See technical specification for details.

Search for the bearing model you need

| NO. | Product | Product Number | Bore | Outer diameter (D) | Width (B) | Mass | Limiting speed | |

|---|---|---|---|---|---|---|---|---|

| 101 |

|

NA 6913 | 65 mm | 90 mm | 45 mm | 0.83 kg | 6300 rpm | |

| 102 |

|

NKIS 65 | 65 mm | 95 mm | 28 mm | 0.64 kg | 6000 rpm | |

| 103 |

|

NKI 70/25 | 70 mm | 95 mm | 25 mm | 0.51 kg | 5600 rpm | |

| 104 |

|

NKI 70/35 | 70 mm | 95 mm | 35 mm | 0.72 kg | 5600 rpm | |

| 105 |

|

NA 4914 | 70 mm | 100 mm | 30 mm | 0.73 kg | 5600 rpm | |

| 106 |

|

NA 6914 | 70 mm | 100 mm | 54 mm | 1.35 kg | 5600 rpm | |

| 107 |

|

NKI 75/25 | 75 mm | 105 mm | 25 mm | 0.64 kg | 5300 rpm | |

| 108 |

|

NA 4915 | 75 mm | 105 mm | 30 mm | 0.78 kg | 5300 rpm | |

| 109 |

|

NKI 75/35 | 75 mm | 105 mm | 35 mm | 0.91 kg | 5300 rpm | |

| 110 |

|

NA 6915 | 75 mm | 105 mm | 54 mm | 1.45 kg | 5300 rpm | |

| 111 |

|

NKI 80/25 | 80 mm | 110 mm | 25 mm | 0.68 kg | 5000 rpm | |

| 112 |

|

NA4916 | 80 mm | 110 mm | 30 mm | 0.88 kg | 5000 rpm | |

| 113 |

|

NKI 80/35 | 80 mm | 110 mm | 35 mm | 0.96 kg | 5000 rpm | |

| 114 |

|

NA 6916 | 80 mm | 110 mm | 54 mm | 1.5 kg | 5000 rpm | |

| 115 |

|

NKI 85/26 | 85 mm | 115 mm | 26 mm | 0.74 kg | 4800 rpm | |

| 116 |

|

NKI 85/36 | 85 mm | 115 mm | 36 mm | 1.05 kg | 4800 rpm | |

| 117 |

|

NA 4917 | 85 mm | 120 mm | 35 mm | 1.25 kg | 4000 rpm | 4500 rpm |

| 118 |

|

NA 6917 | 85 mm | 120 mm | 63 mm | 2.2 kg | 4500 rpm | |

| 119 |

|

NA 6918 | 90 mm | 125 mm | 63 mm | 2.3 kg | 4300 rpm | |

| 120 |

|

NKI 90/26 | 90 mm | 120 mm | 26 mm | 0.78 kg | 4500 rpm | |

| 121 |

|

NKI 90/36 | 90 mm | 120 mm | 36 mm | 1.1 kg | 4500 rpm | |

| 122 |

|

NA 4918 | 90 mm | 125 mm | 35 mm | 1.3 kg | 4300 rpm | |

| 123 |

|

NKI 95/26 | 95 mm | 125 mm | 26 mm | 0.82 kg | 4300 rpm | |

| 124 |

|

NKI 95/36 | 95 mm | 125 mm | 36 mm | 1.15 kg | 4300 rpm | |

| 125 |

|

NA 6919 | 95 mm | 130 mm | 63 mm | 2.5 kg | 4000 rpm | |

| 126 |

|

NKA 4919 | 95 mm | 130 mm | 35 mm | 1.35 kg | 4000 rpm | |

| 127 |

|

NKI 100/30 | 100 mm | 130 mm | 30 mm | 0.99 kg | 4000 rpm | |

| 128 |

|

NKI 100/40 | 100 mm | 130 mm | 40 mm | 1.35 kg | 4000 rpm | |

| 129 |

|

NA 4920 | 100 mm | 140 mm | 40 mm | 1.9 kg | 4000 rpm | |

| 130 |

|

NA 4822 | 110 mm | 140 mm | 30 mm | 1.1 kg | 3800 rpm | |

| 131 |

|

NA 4922 | 110 mm | 150 mm | 40 mm | 2.05 kg | 3600 rpm | |

| 132 |

|

NA 4824 | 120 mm | 150 mm | 30 mm | 1.15 kg | 3600 rpm | |

| 133 |

|

NA 4924 | 120 mm | 165 mm | 45 mm | 2.85 kg | 3400 rpm | |

| 134 |

|

NA 4826 | 130 mm | 165 mm | 35 mm | 1.8 kg | 3200 rpm | |

| 135 |

|

NA 4926 | 130 mm | 180 mm | 50 mm | 3.9 kg | 3000 rpm | |

| 136 |

|

NA 4828 | 140 mm | 175 mm | 35 mm | 1.9 kg | 3000 rpm | |

| 137 |

|

NA 4928 | 140 mm | 190 mm | 50 mm | 4.15 kg | 2800 rpm | |

| 138 |

|

NA 4830 | 150 mm | 190 mm | 40 mm | 2.7 kg | 2800 rpm | |

| 139 |

|

NA 4832 | 160 mm | 200 mm | 40 mm | 2.85 kg | 2600 rpm | |

| 140 |

|

NA 4834 | 170 mm | 215 mm | 45 mm | 3.95 kg | 2400 rpm | |

| 141 |

|

NA 4836 | 180 mm | 225 mm | 45 mm | 4.2 kg | 2400 rpm | |

| 142 |

|

NA 4838 | 190 mm | 240 mm | 50 mm | 5.55 kg | 2200 rpm | |

| 143 |

|

NA 4840 | 200 mm | 250 mm | 50 mm | 5.8 kg | 2000 rpm | |

| 144 |

|

NA 4844 | 220 mm | 270 mm | 50 mm | 6.35 kg | 1900 rpm | |

| 145 |

|

NA 4848 | 240 mm | 300 mm | 60 mm | 9.9 kg | 1700 rpm | |

| 146 |

|

NA 4852 | 260 mm | 320 mm | 10.5 kg | 1500 rpm | ||

| 147 |

|

NA 4856 | 280 mm | 350 mm | 69 mm | 15.5 kg | 1400 rpm | |

| 148 |

|

NA 4860 | 300 mm | 380 mm | 80 mm | 22 kg | 1300 rpm | |

| 149 |

|

NA 4864 | 320 mm | 400 mm | 80 mm | 23 kg | 1200 rpm | |

| 150 |

|

NA 4868 | 340 mm | 420 mm | 80 mm | 24 kg | 1200 rpm | |

| 151 |

|

NA 4872 | 360 mm | 440 mm | 80 mm | 25.5 kg | 1100 rpm | |

| 152 |

|

NA 4876 | 380 mm | 480 mm | 100 mm | 42.5 kg | 1000 rpm |

Features and advantages of QIBR machine-cut rings, needle roller bearings with ribs and inner rings

QIBR machine-cut rings, needle roller bearings with ribs and inner rings solve multiple key problems in various fields, mainly reflected in the following aspects:

1. Compact structure

Due to the use of needle rollers as rolling elements, machine-cut rings, needle roller bearings with ribs and inner rings have a relatively small volume while carrying large radial loads, and can be installed in a limited space, which is particularly suitable for compact mechanical design.

2. Low friction and high efficiency

Due to the precision design between the needle rollers and the cage, machine-cut rings, needle roller bearings with ribs and inner rings have lower friction losses, reduced heat generation, and improved working efficiency. This makes it suitable for high-speed, high-efficiency working environments.

3. Strong durability

The cage can maintain the stable position of the needle rollers, reduce mutual contact and wear between the needle rollers, and thus extend the service life of the bearings. Reasonable clearance and precision design ensure the stability and reliability of the bearings at work.

4. Low noise and vibration

Due to the reasonable structural design between the needle roller and the cage, the possibility of contact between the needle rollers is reduced, and the noise and vibration of the bearing are reduced, so it is suitable for working environments that require low noise.

5. Adapt to high speed

Due to the small shape of the needle roller and the small contact area, the machined ring, the needle roller bearing with ribs and inner ring are suitable for high speed applications and are not prone to excessive friction or overheating due to excessive speed.

The performance improvement and solution of QIBR machined ring, needle roller bearing with flange and inner ring

1. Improved materials

Selection of high-performance materials: Using materials with higher hardness, wear resistance and corrosion resistance can significantly improve the durability and stability of bearings.

2. Optimized cage design

Cage structure optimization: Optimize the cage structure design to achieve better needle roller arrangement and uniform load distribution. Improving the cage structure can reduce the mutual collision of needle rollers and improve running stability and efficiency.

Reduced contact area: By optimizing the geometry of the cage and the arrangement of the needle rollers, the contact area between the needle rollers is reduced, thereby reducing friction and wear.

3. Improved lubrication performance

High-efficiency lubricating materials: Use grease or lubricating oil that is more suitable for high temperature and high pressure environments to ensure that the lubricating oil can maintain stable performance under long-term work, thereby reducing bearing friction and improving durability.

4. Improved precision

By improving manufacturing precision, reducing the gap and error between bearing components, and ensuring that the contact between the needle roller and the cage is more uniform and stable. This can not only improve the performance of the bearing, but also extend the service life and reduce noise and vibration.

Main application areas of QIBR machined rings, needle roller bearings with ribs and inner rings

1. Agricultural machinery

Agricultural equipment: In heavy agricultural machinery such as tractors, tillers, harvesters, etc., machined rings, needle roller bearings with ribs and inner rings are used to provide strong load-bearing capacity and help reduce space occupation so as to adapt to small mechanical spaces.

2. Industrial machinery

Reducers and transmission devices: Machined rings, needle roller bearings with ribs and inner rings are widely used in reducers, gear transmission systems, etc., which can withstand large radial loads, reduce space occupation, and improve transmission efficiency.

Automation equipment: In the transmission system of automated production lines, machined rings, needle roller bearings with ribs and inner rings are used to support rotating parts to ensure the accuracy and stability of the equipment.

3. Aircraft engines

Machined rings, needle roller bearings with ribs and inner rings are often used on turbine shafts, turbines and other rotating parts in aircraft engines to ensure smooth operation at high speeds and withstand radial loads generated during high-speed rotation.

4. Washing machine

In the motor and transmission system of the washing machine, needle bearings play a role in supporting and reducing friction.