Image may differ from product. See technical specification for details.

Search for the bearing model you need

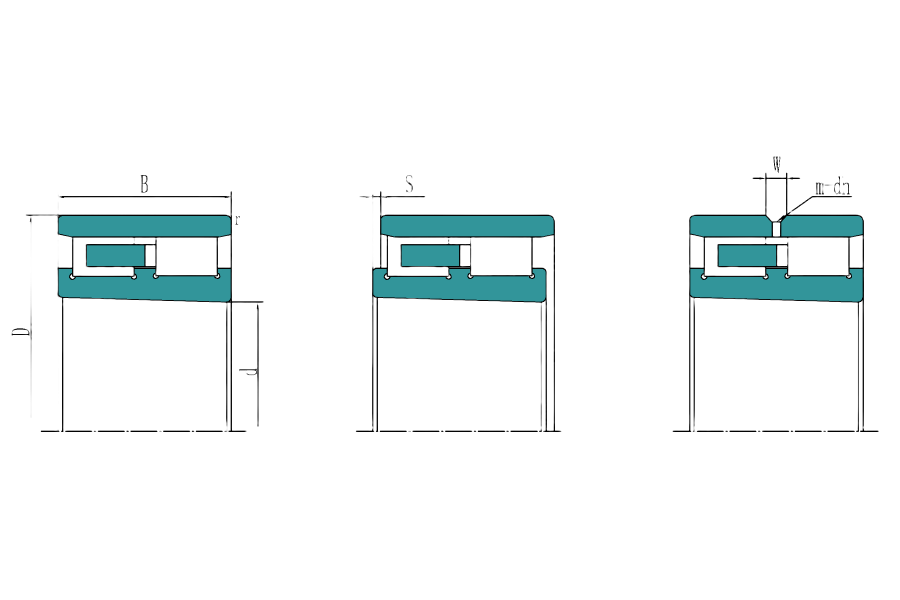

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Material

52100、100Cr6、SUJ2

Inner diameter (d)

25-440mm

Outer diameter (D)

40-1100mm

Mass

0.1-600kg

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Spinspindle of large motors,Machine tool spindle

| NO. | Product | Product Number | Inner diameter (d) | Outer diameter (D) | Radial dynamic load | Static load rating,radial | Weight | Width (B) |

|---|---|---|---|---|---|---|---|---|

| 301 |

|

NN3048MBKR | 240 mm | 360 mm | 980 KN | 1600 KN | 30.4 kg | 92 mm |

| 302 |

|

NN3048MB | 240 mm | 360 mm | 980 KN | 1600 KN | 30.4 kg | 92 mm |

| 303 |

|

NN3952MBKR | 260 mm | 360 mm | 775 KN | 1380 KN | 21.4 kg | 75 mm |

| 304 |

|

NN3952MB | 260 mm | 360 mm | 775 KN | 1380 KN | 21.4 kg | 75 mm |

| 305 |

|

NN4952MBKR | 260 mm | 360 mm | 1070 KN | 2100 KN | 28.4 kg | 100 mm |

| 306 |

|

NN4952MB | 260 mm | 360 mm | 1070 KN | 2100 KN | 28.4 kg | 100 mm |

| 307 |

|

NNU4952MBKR | 260 mm | 360 mm | 1070 KN | 2100 KN | 28.3 kg | 100 mm |

| 308 |

|

NNU4952MB | 260 mm | 360 mm | 1070 KN | 2100 KN | 28.3 kg | 100 mm |

| 309 |

|

NN3052KR | 260 mm | 400 mm | 1030 KN | 1920 KN | 44.7 kg | 104 mm |

| 310 |

|

NN3052 | 260 mm | 400 mm | 1030 KN | 1920 KN | 44.7 kg | 104 mm |

| 311 |

|

NN3956MBKR | 280 mm | 380 mm | 695 KN | 1460 KN | 22.8 kg | 75 mm |

| 312 |

|

NN3956MB | 280 mm | 380 mm | 695 KN | 1460 KN | 22.8 kg | 75 mm |

| 313 |

|

NN4956KR | 280 mm | 380 mm | 960 KN | 2230 KN | 30.1 kg | 100 mm |

| 314 |

|

NN4956 | 280 mm | 380 mm | 960 KN | 2230 KN | 30.1 kg | 100 mm |

| 315 |

|

NNU4956KR | 280 mm | 380 mm | 960 KN | 2230 KN | 33.1 kg | 100 mm |

| 316 |

|

NNU4956 | 280 mm | 380 mm | 960 KN | 2230 KN | 33.1 kg | 100 mm |

| 317 |

|

NN3056KR | 280 mm | 420 mm | 1080 KN | 2080 KN | 47.7 kg | 106 mm |

| 318 |

|

NN3056 | 280 mm | 420 mm | 1080 KN | 2080 KN | 47.7 kg | 106 mm |

| 319 |

|

NN3960KR | 300 mm | 420 mm | 855 KN | 1800 KN | 36.2 kg | 90 mm |

| 320 |

|

NN3960 | 300 mm | 420 mm | 855 KN | 1800 KN | 36.2 kg | 90 mm |

| 321 |

|

NN4960KR | 300 mm | 420 mm | 1230 KN | 2870 KN | 47.6 kg | 118 mm |

| 322 |

|

NN4960 | 300 mm | 420 mm | 1230 KN | 2870 KN | 47.6 kg | 118 mm |

| 323 |

|

NNU4960KR | 300 mm | 420 mm | 1230 KN | 2870 KN | 47.6 kg | 118 mm |

| 324 |

|

NNU4960 | 300 mm | 420 mm | 1230 KN | 2870 KN | 47.6 kg | 118 mm |

| 325 |

|

NN3060KR | 300 mm | 460 mm | 1290 KN | 2460 KN | 66.5 kg | 118 mm |

| 326 |

|

NN3060 | 300 mm | 460 mm | 1290 KN | 2460 KN | 66.5 kg | 118 mm |

| 327 |

|

NN3964KR | 320 mm | 440 mm | 880 KN | 1910 KN | 38.2 kg | 90 mm |

| 328 |

|

NN3964 | 320 mm | 440 mm | 880 KN | 1910 KN | 38.2 kg | 90 mm |

| 329 |

|

NN4964KR | 320 mm | 440 mm | 1260 KN | 3050 KN | 50.3 kg | 118 mm |

| 330 |

|

NN4964 | 320 mm | 440 mm | 1260 KN | 3050 KN | 50.3 kg | 118 mm |

| 331 |

|

NNU4964KR | 320 mm | 440 mm | 1260 KN | 3050 KN | 50.3 kg | 118 mm |

| 332 |

|

NNU4964 | 320 mm | 440 mm | 1260 KN | 3050 KN | 50.3 kg | 118 mm |

| 333 |

|

NN3064KR | 320 mm | 480 mm | 1350 KN | 2670 KN | 71.8 kg | 121 mm |

| 334 |

|

NN3064 | 320 mm | 480 mm | 1350 KN | 2670 KN | 71.8 kg | 121 mm |

| 335 |

|

NN4968KR | 340 mm | 460 mm | 1350 KN | 3400 KN | 52.6 kg | 118 mm |

| 336 |

|

NN4968 | 340 mm | 460 mm | 1350 KN | 3400 KN | 52.6 kg | 118 mm |

| 337 |

|

NNU4968KR | 340 mm | 460 mm | 1350 KN | 3400 KN | 52.9 kg | 118 mm |

| 338 |

|

NNU4968 | 340 mm | 460 mm | 1350 KN | 3400 KN | 52.9 kg | 118 mm |

| 339 |

|

NN3068KR | 340 mm | 520 mm | 1670 KN | 3300 KN | 95.6 kg | 133 mm |

| 340 |

|

NN3068 | 340 mm | 520 mm | 1670 KN | 3300 KN | 95.6 kg | 133 mm |

| 341 |

|

NN3972KR | 360 mm | 480 mm | 930 KN | 2130 KN | 42.1 kg | 90 mm |

| 342 |

|

NN3972 | 360 mm | 480 mm | 930 KN | 2130 KN | 42.1 kg | 90 mm |

| 343 |

|

NN4972KR | 360 mm | 480 mm | 1390 KN | 3550 KN | 55.1 kg | 118 mm |

| 344 |

|

NN4972 | 360 mm | 480 mm | 1390 KN | 3550 KN | 55.1 kg | 118 mm |

| 345 |

|

NNU4972KR | 360 mm | 480 mm | 1390 KN | 3550 KN | 55.2 kg | 118 mm |

| 346 |

|

NNU4972 | 360 mm | 480 mm | 1390 KN | 3550 KN | 55.2 kg | 118 mm |

| 347 |

|

NN3072KR | 360 mm | 540 mm | 1700 KN | 3450 KN | 99.7 kg | 134 mm |

| 348 |

|

NN3072 | 360 mm | 540 mm | 1700 KN | 3450 KN | 99.7 kg | 134 mm |

| 349 |

|

NN3976KR | 380 mm | 520 mm | 1250 KN | 2730 KN | 63.5 kg | 106 mm |

| 350 |

|

NN3976 | 380 mm | 520 mm | 1250 KN | 2730 KN | 63.5 kg | 106 mm |

| 351 |

|

NN4976KR | 380 mm | 520 mm | 1880 KN | 4600 KN | 81.3 kg | 140 mm |

| 352 |

|

NN4976 | 380 mm | 520 mm | 1880 KN | 4600 KN | 81.3 kg | 140 mm |

| 353 |

|

NNU4976KR | 380 mm | 520 mm | 1880 KN | 4600 KN | 88.8 kg | 140 mm |

| 354 |

|

NNU4976 | 380 mm | 520 mm | 1880 KN | 4600 KN | 88.8 kg | 140 mm |

| 355 |

|

NN3076KR | 380 mm | 560 mm | 1770 KN | 3700 KN | 113 kg | 135 mm |

| 356 |

|

NN3076 | 380 mm | 560 mm | 1770 KN | 3700 KN | 113 kg | 135 mm |

| 357 |

|

NN4980KR | 400 mm | 540 mm | 1940 KN | 4900 KN | 84.1 kg | 140 mm |

| 358 |

|

NN4980 | 400 mm | 540 mm | 1940 KN | 4900 KN | 84.1 kg | 140 mm |

| 359 |

|

NNU4980KR | 400 mm | 540 mm | 1940 KN | 4900 KN | 85.1 kg | 140 mm |

| 360 |

|

NNU4980 | 400 mm | 540 mm | 1940 KN | 4900 KN | 85.1 kg | 140 mm |

| 361 |

|

NN3080KR | 400 mm | 600 mm | 2090 KN | 4300 KN | 138 kg | 148 mm |

| 362 |

|

NN3080 | 400 mm | 600 mm | 2090 KN | 4300 KN | 138 kg | 148 mm |

| 363 |

|

NN4984K | 420 mm | 560 mm | 2000 KN | 5150 KN | 87.9 kg | 140 mm |

| 364 |

|

NN4984 | 420 mm | 560 mm | 2000 KN | 5150 KN | 87.9 kg | 140 mm |

| 365 |

|

NNU4984K | 420 mm | 560 mm | 2000 KN | 5150 KN | 88.4 kg | 140 mm |

| 366 |

|

NNU4984 | 420 mm | 560 mm | 2000 KN | 5150 KN | 88.4 kg | 140 mm |

| 367 |

|

NN3084K | 420 mm | 620 mm | 2130 KN | 4450 KN | 145 kg | 150 mm |

| 368 |

|

NN3084 | 420 mm | 620 mm | 2130 KN | 4450 KN | 145 kg | 150 mm |

| 369 |

|

NN4988K | 440 mm | 600 mm | 2370 KN | 6000 KN | 123 kg | 160 mm |

| 370 |

|

NN4988 | 440 mm | 600 mm | 2370 KN | 6000 KN | 123 kg | 160 mm |

| 371 |

|

NNU4988K | 440 mm | 600 mm | 2370 KN | 6000 KN | 123 kg | 160 mm |

| 372 |

|

NNU4988 | 440 mm | 600 mm | 2370 KN | 6000 KN | 123 kg | 160 mm |

| 373 |

|

NN3088K | 440 mm | 650 mm | 2360 KN | 4900 KN | 166 kg | 157 mm |

| 374 |

|

NN3088 | 440 mm | 650 mm | 2360 KN | 4900 KN | 166 kg | 157 mm |

| 375 |

|

NN3992K | 460 mm | 620 mm | 1610 KN | 3700 KN | 94.5 kg | 118 mm |

| 376 |

|

NN3992 | 460 mm | 620 mm | 1610 KN | 3700 KN | 94.5 kg | 118 mm |

| 377 |

|

NN4992K | 460 mm | 620 mm | 2400 KN | 6200 KN | 127 kg | 160 mm |

| 378 |

|

NN4992 | 460 mm | 620 mm | 2400 KN | 6200 KN | 127 kg | 160 mm |

| 379 |

|

NNU4992K | 460 mm | 620 mm | 2400 KN | 6200 KN | 128 kg | 160 mm |

| 380 |

|

NNU4992 | 460 mm | 620 mm | 2400 KN | 6200 KN | 128 kg | 160 mm |

| 381 |

|

NN3092K | 460 mm | 680 mm | 2550 KN | 5350 KN | 189 kg | 163 mm |

| 382 |

|

NN3092 | 460 mm | 680 mm | 2550 KN | 5350 KN | 189 kg | 163 mm |

| 383 |

|

NN4996K | 480 mm | 650 mm | 2690 KN | 7000 KN | 151 kg | 170 mm |

| 384 |

|

NN4996 | 480 mm | 650 mm | 2690 KN | 7000 KN | 151 kg | 170 mm |

| 385 |

|

NNU4996K | 480 mm | 650 mm | 2690 KN | 7000 KN | 150 kg | 170 mm |

| 386 |

|

NNU4996 | 480 mm | 650 mm | 2690 KN | 7000 KN | 150 kg | 170 mm |

| 387 |

|

NN3096K | 480 mm | 700 mm | 2600 KN | 5550 KN | 211 kg | 165 mm |

| 388 |

|

NN3096 | 480 mm | 700 mm | 2600 KN | 5550 KN | 211 kg | 165 mm |

| 389 |

|

NN49/500K | 500 mm | 670 mm | 2720 KN | 7200 KN | 155 kg | 170 mm |

| 390 |

|

NN49/500 | 500 mm | 670 mm | 2720 KN | 7200 KN | 155 kg | 170 mm |

| 391 |

|

NNU49/500K | 500 mm | 670 mm | 2720 KN | 7200 KN | 157 kg | 170 mm |

| 392 |

|

NNU49/500 | 500 mm | 670 mm | 2720 KN | 7200 KN | 157 kg | 170 mm |

| 393 |

|

NN30/500K | 500 mm | 720 mm | 2580 KN | 5600 KN | 205 kg | 167 mm |

| 394 |

|

NN30/500 | 500 mm | 720 mm | 2580 KN | 5600 KN | 205 kg | 167 mm |

| 395 |

|

NN39/530K | 530 mm | 710 mm | 2040 KN | 4900 KN | 139 kg | 136 mm |

| 396 |

|

NN39/530 | 530 mm | 710 mm | 2040 KN | 4900 KN | 139 kg | 136 mm |

| 397 |

|

NN49/530K | 530 mm | 710 mm | 3050 KN | 8150 KN | 185 kg | 180 mm |

| 398 |

|

NN49/530 | 530 mm | 710 mm | 3050 KN | 8150 KN | 185 kg | 180 mm |

| 399 |

|

NNU49/530K | 530 mm | 710 mm | 3050 KN | 8150 KN | 186 kg | 180 mm |

| 400 |

|

NNU49/530 | 530 mm | 710 mm | 3050 KN | 8150 KN | 186 kg | 180 mm |

The double row cylindrical roller bearings have addressed several key issues across various fields, primarily reflected in the following aspects:

1. High rigidity

Due to the double row roller design, these bearings offer higher rigidity compared to single row bearings, effectively reducing vibration and improving equipment stability.

2. Adaptability to high-speed operation:

While primarily designed to handle heavy loads, the precision manufacturing process allows these bearings to support high-speed operation while maintaining smooth performance.

3. Effective noise control

High-precision double row cylindrical roller bearings, through precise installation, proper lubrication, and advanced monitoring systems, can effectively reduce operational noise and enhance overall equipment performance.

4. High cost-effectiveness

The design of double row precision cylindrical roller bearings allows for efficient load support in relatively compact spaces. Their use can reduce costs while improving rigidity and stability.

Performance enhancements and solutions for double row cylindrical roller bearings

1. Dustproof and waterproof design

Especially in harsh environments, bearings require sufficient protection to prevent dust, mud, and other contaminants from entering the bearing interior. Sealing designs can achieve this, thereby avoiding impacts on bearing performance and lifespan.

2. Roller optimization

Optimizing roller shapes can reduce contact stress, improve load capacity, and enhance durability. Surface treatments on rollers can reduce friction, improve rolling precision and load capacity, and extend bearing life.

3. Improved manufacturing precision

Using advanced foreign processing equipment and techniques, such as precision grinding and superfinishing, enhances the geometric accuracy of inner and outer rings and rollers, reducing machining errors and improving rotational precision and surface finish.

4. Enhanced material performance

Surface coating technologies can improve wear resistance and corrosion resistance, effectively extending bearing life, especially in harsh working environments where bearing performance can be significantly enhanced.

Main application fields of double row cylindrical roller bearing

1. Machine tools

In high-precision machine tools, double row precision cylindrical roller bearings are used to withstand heavy loads, ensuring machining accuracy and stability.

2. Locomotive axle boxes

These bearings are widely used in railway locomotive axle boxes. Their design can withstand high loads and effectively prevent the ingress of dust and moisture, improving reliability and service life.

3. Robotics

In industrial and service robots, precision cylindrical roller bearings ensure precise motion and high efficiency.

4. High-precision instruments:

In precision measuring instruments and optical equipment, these bearings support rotating components, ensuring instrument accuracy and stability.