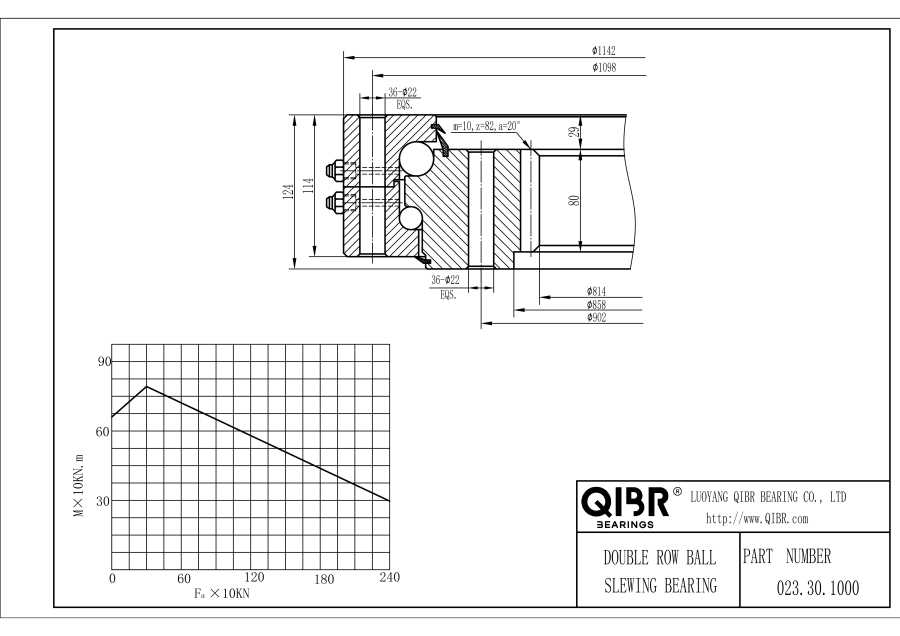

023.30.1000

- Inner diameter:

- 858 mm

- Outer diameter:

- 1142 mm

- Width:

- 124 mm

We will provide you with the most suitable solution.

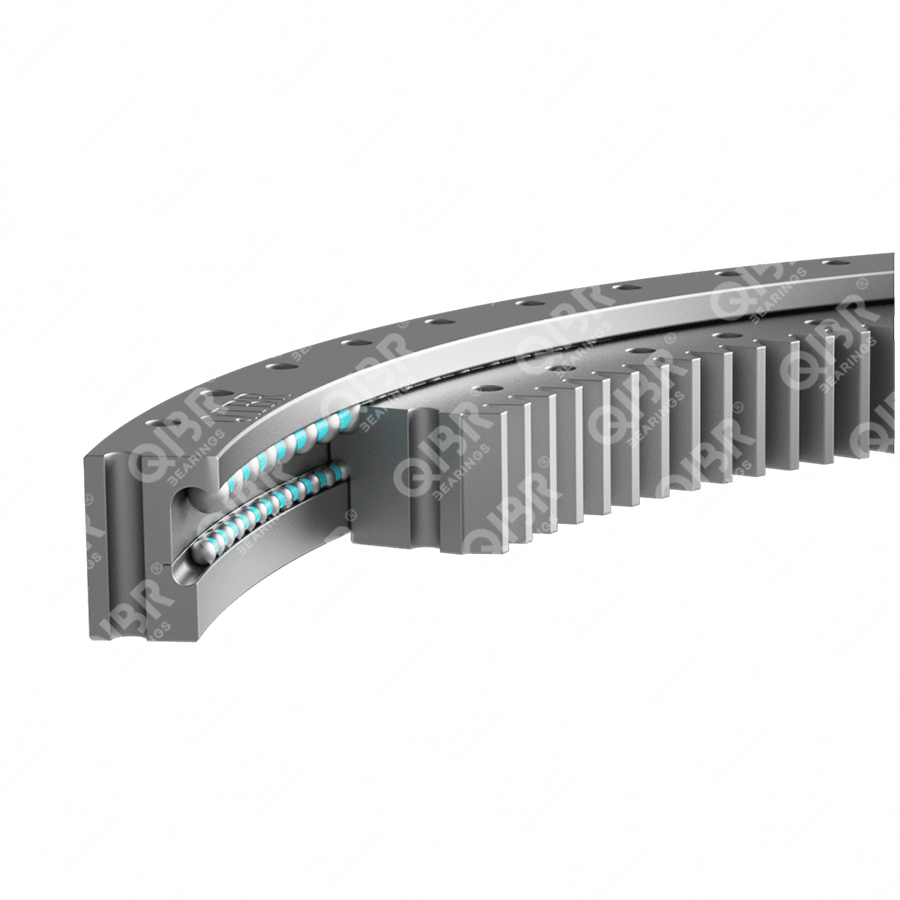

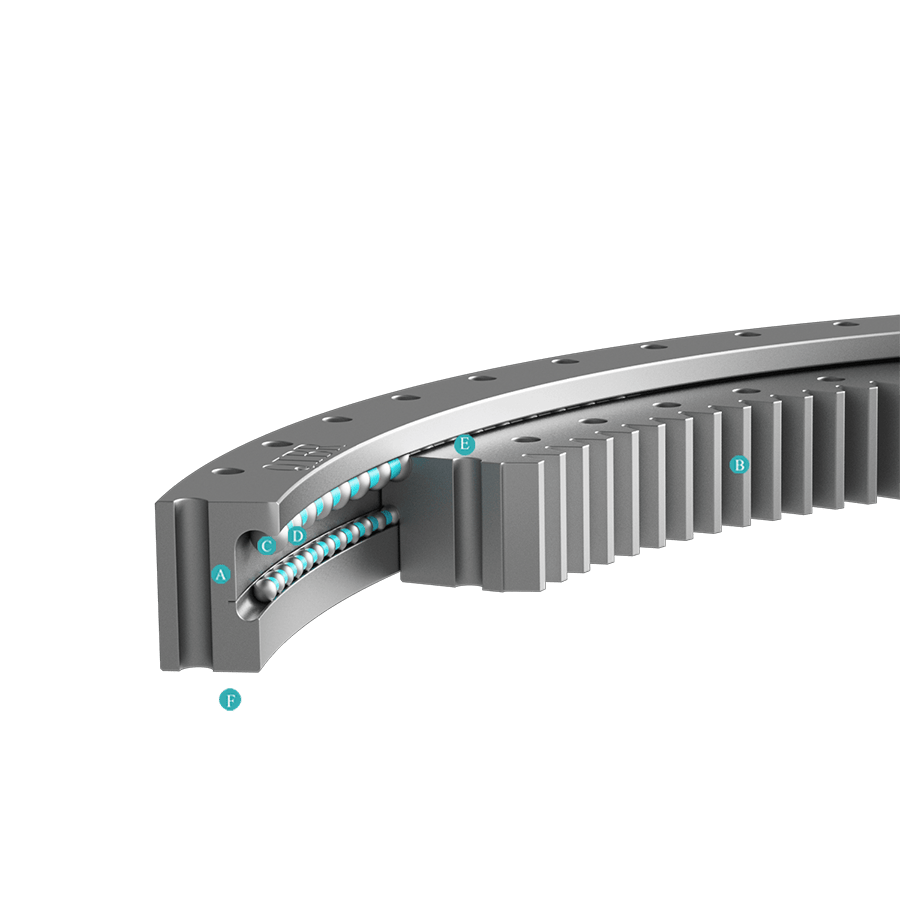

Image may differ from product. See technical specification for details.

Specifications

Seris - 023.30.1000

Description

QIBR - 023.30.1000 Slewing Bearing Advantages and Applications

023.30.1000 Slewing Bearing has high precision, high speed and stable operation. Inner diameter (d) is 858 mm,Outer diameter (D) is 1142 mm,Overall height (H) is 124 mm. It is suitable for self-propelled aerial work platforms, road rollers, centrifuges, aircraft, excavators and cranes, etc. and is the most widely used bearing in working conditions requiring high speed.

QIBR - 023.30.1000 Slewing Bearing Characteristics

023.30.1000 Slewing Bearing, long service life, wear resistance. 023.30.1000 Slewing Bearing, can bear radial load, axial load and overturning moment at the same time, suitable for mechanical equipment requiring high speed.

023.30.1000 Slewing Bearing Features and Advantages

Compact design: Compact structure, it can be installed in space-constrained environments, and has a wider range of applications.

High load capacity: It can withstand axial, radial and overturning moments at the same time, suitable for heavy-duty applications.

Superior precision: Maintain high precision during use and reduce errors in equipment operation.

High temperature and wear resistance: Made of high-temperature bearing steel, with good wear resistance and strength.

Application: Widely used in lifting machinery, engineering machinery, transportation machinery, mining machinery, metallurgical machinery, medical equipment, ships, warships, radar, wind power generation and other fields.

QIBR - 023.30.1000 Slewing Bearing Optimization

Grease replacement: Replace grease with other greases such as SFK, Mobil, Krupp, etc. to optimize the working performance and use conditions of the bearing.

Coating optimization: Provide other coatings such as zinc plating or nickel plating to enhance corrosion resistance and wear resistance and extend its service life in harsh environments.

Process optimization: Optimize the bearing production process, increase the bearing operating temperature range, and improve the bearing accuracy and stability.

More customization: QIBR can optimize the bearing structure design according to customers’ drawings or equipment requirements to meet equipment needs.

QIBR - 023.30.1000 Slewing support bearing quality control

Dimension measurement: Use a variety of professional high-precision instruments to measure multiple dimensions of the bearing, with the highest accuracy up to 0.01mm.

Rotation accuracy: Use a dial indicator to measure small flaws or deviations on the bearing surface, with a measurement accuracy of up to 0.01mm.

Hardness measurement: Use a Leeb hardness tester to measure the bearing surface hardness, with a measurement accuracy of ±6HLD.

Metallographic analysis: Use a professional metallographic microscope to analyze the internal metallographic structure of the metal.

Geometric tolerance: Use a roundness meter to measure the bearing geometry and relative position.

Noise monitoring: Use a vibration meter to monitor the vibration during operation and obtain noise data.

Features & Benefits

The slewing bearing consists of five essential components: the inner ring, which rotates; the outer ring, which remains stationary; rolling elements that facilitate movement; spacers for even distribution; and seals that protect against contaminants and retain lubrication.

Downloads