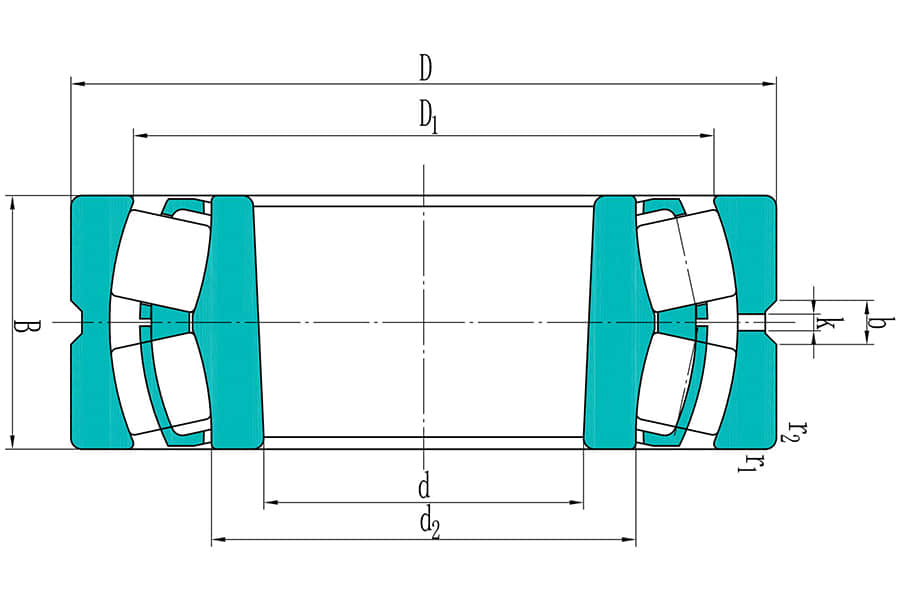

21312 EK

- Inner diameter:

- 60 mm

- Outer diameter:

- 130 mm

- Width:

- 31 mm

- Mass:

- 2.1 Kg

We will provide you with the most suitable solution.

Image may differ from product. See technical specification for details.

Specifications

Seris - 21312 EK

Description

QIBR - 21312 EK Spherical Roller Bearing Advantages and Applications

21312 EK Spherical Roller Bearing, low friction, high rigidity, Inner diameter (d) is 60 mm, Outer diameter (D) is 130 mm, Overall width (B) is 31 mm, Weight is 2.1 kg, suitable for motors, crushers, rolling mills and ship steering gears, etc., and is the most widely used bearing in working conditions with high performance requirements.

QIBR - 21312 EK Spherical Roller Bearing Characteristics

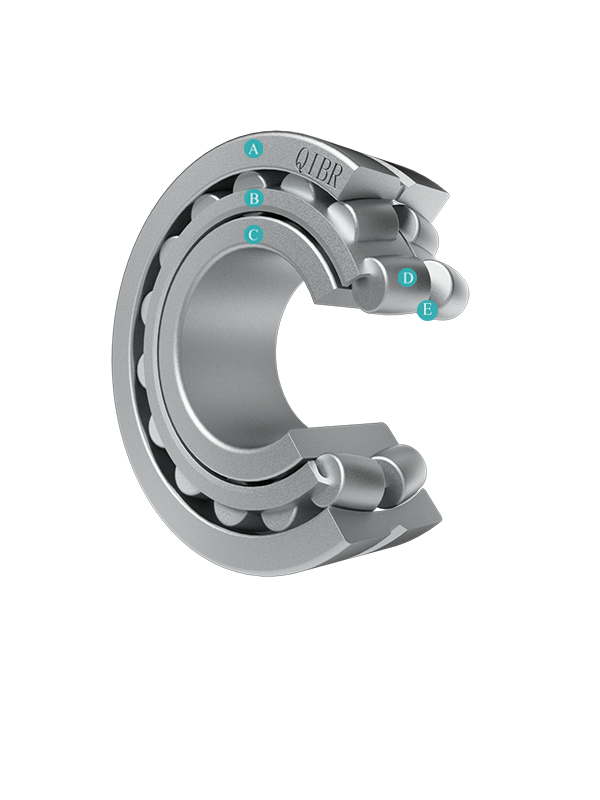

21312 EK Spherical Roller Bearing, easy to install and maintain, reducing overall costs. 21312 EK Spherical Roller Bearing, can withstand radial loads and bidirectional axial loads at the same time, suitable for mechanical equipment with high requirements for stability.

21312 EK Spherical Roller Bearings Features and Advantages

High load capacity: Capable of withstanding large radial loads and bidirectional axial loads, making it suitable for heavy-duty and impact vibration load environments.

Self-aligning Performance: The outer ring raceway is spherical, effectively compensating for misalignment due to installation errors or shaft deformation.

High-Temperature Performance: Spherical roller bearings have a wide operating temperature range, suitable for applications in high-temperature environments.

Vibration Resistance: Capable of accommodating changes in relative position due to thermal expansion or installation errors, suitable as a free-end bearing.

Application: Widely used in mining, marine, milling applications, coal machinery, wind turbines, paper printing, steel metallurgy, electric vehicles, and large machinery.

QIBR - 21312 EK Spherical Roller Bearings Optimization

High-Performance Materials: Different materials such as GCr15, AISI 440C, and 42CrMo can be provided based on customer requirements.

Structural Optimization: The bearing structure and geometry can be optimized according to customer needs to enhance alignment performance and operational stability.

Lubricating Grease: Selection of appropriate lubricants like Mobil SHC 100, SKF LGEP 2, or Shell Gadus S2 V220 based on the bearing's working conditions or customer requirements.

Customization: Bearings can be designed and optimized by QIBR according to customer-specific working conditions and requirements.

QIBR - 21312 EK Spherical Roller Bearings Quality Control

Dimension measurement: Using various high-precision instruments, multiple dimensions of the bearing are measured with an accuracy of up to 0.001mm.

Rotation accuracy: A dial gauge measures minor surface flaws or deviations, with measurement accuracy reaching 0.001mm.

Hardness measurement: Surface hardness is measured using a hardness tester, with an accuracy of ±0.5HRC.

Metallographic analysis: A professional metallographic microscope is used to analyze the internal metallographic structure of the metal.

Form and Position Tolerance: A profilometer is used to measure the geometric shape and relative position of the bearing.

Noise monitoring: Vibration levels during operation are monitored using a vibration meter to obtain noise data.

Raw material control: Steel and parts are sourced from ISO 14001-certified suppliers, ensuring product stability while promoting sustainable development.

Features & Benefits

Spherical roller bearings are rolling bearings that can bear both radial and axial loads. The "spherical" in its name refers to its ability to self-adjust to accommodate axis deviation or tilt when the bearing is installed. This type of bearing is usually composed of an inner ring, an outer ring, rollers (cylindrical rollers) and a cage.

Downloads