Newsroom

Analysis and Control of Factors Affecting the Service Life of the Steel Ball

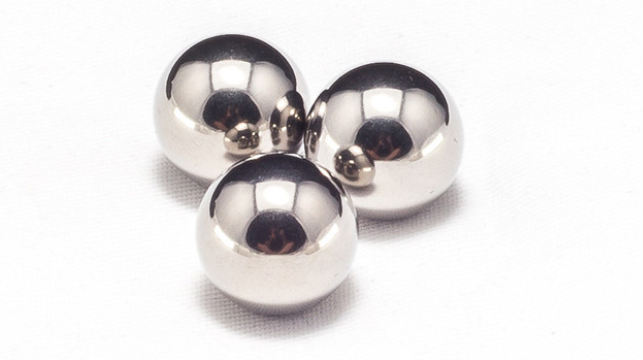

2025-07-18The reliability of steel ball lifespan directly impacts the overall service life of bearings. Ensuring consistent quality across production batches is critical for steel balls to be applied in high-end bearings, such as those used in aerospace, high-speed rail, and high-performance automotive hub assemblies.

Key Factors Affecting the Reliability of Steel Ball Lifespan

In addition to the commonly known influencing factors—such as raw material quality, heat treatment, and surface finish—there is a less detectable but highly detrimental factor: soft spots on the steel ball surface.

1.Soft Spots: Definition and Hazards

A soft spot refers to one or more points on the surface of a steel ball where the hardness is lower than the required 61 HRC, typically ranging from 30 to 60 HRC—higher than the raw material hardness, but far below the acceptable value. This defect may result in:

- Surface scratches during subsequent processing, often appearing as white spots with non-directional marks;

- Early fatigue failures, as soft spots act as stress concentration points during operation.

2.Challenges in Soft Spot Detection

Although eddy current sorting can identify some soft spots, the wide variation in hardness and area size limits detection accuracy. Optical sorting machines are even less effective, often failing to detect and eliminate such defects.

Burn Marks: A Major Cause of Reduced Steel Ball Lifespan

Burn marks are the most common defect occurring during the hard grinding stage. They can induce soft spots and significantly compromise steel ball reliability. Burn marks can be categorized based on their formation mechanism:

1. Linear Burn Marks (Secondary Quenching or Tempering)

Excessive grinding speed and pressure cause high friction temperatures at contact points. If the temperature reaches the quenching or tempering range and is then rapidly cooled by coolant, linear burn marks occur on the steel ball surface.

2. Point Burn Marks

During grinding, impact from the grinding wheel or fixed plates generates localized high temperatures. If rapidly cooled, these impact points form point-shaped burn marks.

3. Bipolar Burn Marks

If the steel ball only contacts one or both sides of the grinding groove instead of full contact, grinding pressure concentrates in limited areas, generating localized overheating and eventually forming bipolar burn marks upon cooling.

Detection Difficulties:

- Manual acid-wash sorting has low reliability;

- Even advanced optical inspection and eddy current testing systems still show cases of missed detections.

Strategies for Improving Steel Ball Reliability

1. Process Control During Hard Grinding

- Regulate grinding pressure and temperature;

- Ensure consistent coolant flow and check for even grinding wheel wear.

2. Optimized Defect Detection Methods

- Combine advanced eddy current testing with machine vision systems;

- Reduce reliance on manual sorting to improve efficiency and consistency.

3. Batch Consistency Management

- Establish traceability systems for each production batch;

- Apply multidimensional screening for critical applications to ensure full lifecycle performance.

Strategies for Improving Steel Ball Reliability

Since the reliability of steel balls affects overall bearing performance, early failure of steel balls may result in equipment malfunction. Understanding early detection methods for bearing failure is therefore essential:

- Auditory Inspection: Abnormal noise can indicate cracks or surface defects;

- Vibration Analysis: Detects abnormal frequencies or amplitudes signaling internal faults;

- Temperature Monitoring: Sudden rises may suggest internal damage or lubrication failure;

- Lubricant Analysis: Presence of metal particles can indicate ongoing wear and potential failure.

For more information, feel free to contact QIBR