Newsroom

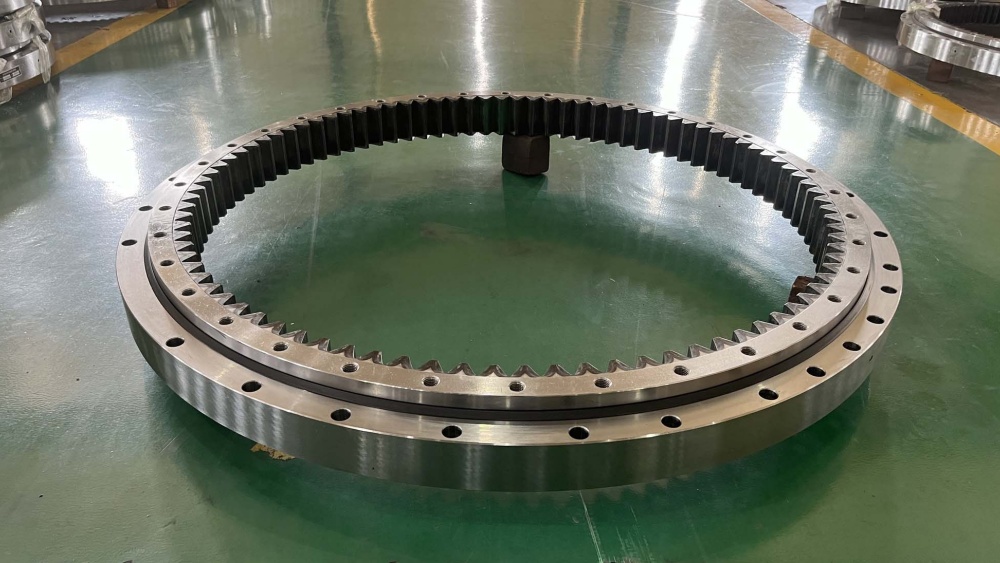

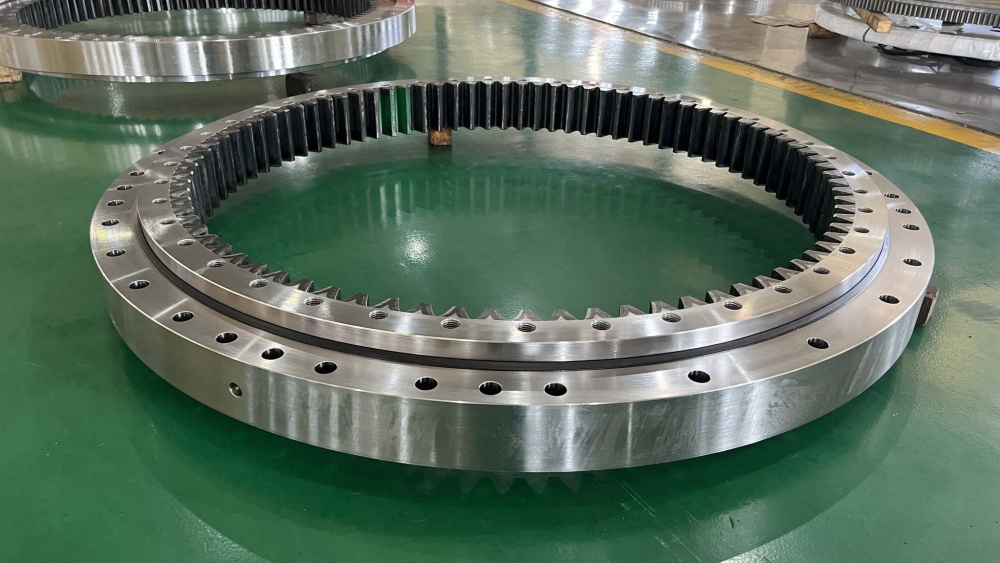

How to Dismantle a Slewing Bearing?

In the lifecycle of a bearing, two unavoidable processes are installation and dismantling. When a bearing approaches the end of its service life or requires replacement due to various reasons, dismantling becomes necessary. So, how exactly can a slewing bearings be removed? This article provides a detailed guide on different dismantling methods, tools, and precautions to ensure a smooth and safe process.

1. Methods for Dismantling Slewing Bearings

1.1 Normal Clearance Fit

When the bearing has a standard clearance fit (not excessively tight or loose), and the support dimensions are correctly designed, dismantling is relatively straightforward—provided there is no deformation from overuse or rust-induced seizure.

Techniques:

Percussion Method:

Use a copper rod or another soft metal rod with a diameter smaller than the bearing’s inner ring.

Align the rod properly and gently tap it with a hammer to push the bearing out.

This method is suitable for small to medium-sized bearings.

Puller Tool Method:

A mechanical or hydraulic puller can be used to gradually extract the slewing bearings.

The puller’s arms should grip the inner ring while the central screw applies force to push the bearing out.

This method is efficient for bearings that are not excessively tight.

1.2 Inner Ring Interference Fit

When the bearing has an interference fit (where the inner ring is tightly pressed onto the shaft), specialized tools are required for removal.

Tools & Techniques:

Mechanical Pullers (Threaded Type):

A traditional tool where a central screw is aligned with the shaft’s center hole.

Apply a small amount of grease to reduce friction.

The puller’s hooks grip the inner ring, and rotating the central screw gradually extracts the bearing.

Hydraulic Pullers:

A more advanced tool that uses hydraulic pressure instead of manual force.

The piston extends under pressure, smoothly pulling the bearing out.

Faster and more efficient than mechanical pullers, especially for batch dismantling.

For small bearings, mechanical pullers are sufficient, but for larger or multiple bearings, hydraulic systems are preferred.

1.3 Outer Ring Interference Fit

If the bearing’s outer ring is tightly fitted into the housing, removal requires additional considerations.

Key Requirements:

The housing’s shoulder diameter must not be smaller than the bearing’s required support diameter.

If possible, design the housing with 2-3 notches to allow puller hooks to grip securely.

Techniques:

Induction Heating (Flexible Coil Method):

Heat the housing (not the bearing) to expand it slightly.

The thermal expansion loosens the fit, allowing easier removal.

This method is ideal for large bearings or those with high interference.

Mechanical Extraction:

If heating is not feasible, a heavy-duty puller can be used, but care must be taken to avoid damaging the housing.

2. Precautions for Dismantling Slewing Bearings

2.1 Proper Use of Pullers

Always hook the puller onto the inner ring, not the outer ring, to prevent excessive loosening or damage.

Ensure the puller’s screw is aligned with the shaft’s center to avoid misalignment and uneven force distribution.

Monitor the puller’s grip to prevent slippage, which can damage the bearing or tool.

2.2 Heating Method Considerations

Protect the shaft from heat to prevent thermal expansion that could complicate removal.

Only heat the housing, not the bearing itself, to avoid structural damage.

Use controlled heating to prevent warping or metallurgical changes.

2.3 Safety Measures

Wear protective gloves and goggles to prevent injuries from flying debris or hot surfaces.

Ensure the work area is stable to avoid accidents from falling tools or bearings.

If using hydraulic tools, check for leaks or pressure malfunctions before operation.

3. Additional Tips for Efficient Dismantling

Lubrication: Applying penetrating oil before removal can help loosen rusted bearings.

Inspection: After removal, check the shaft and housing for wear or damage before installing a new bearing.

Tool Selection: Choose the right puller size to avoid excessive force that could deform components.

Conclusion

Dismantling a slewing bearing requires careful consideration of fit type, tool selection, and safety measures. Whether using mechanical pullers, hydraulic systems, or thermal methods, following proper techniques ensures a smooth and damage-free process. By adhering to these guidelines, maintenance personnel can efficiently remove bearings while minimizing risks and prolonging equipment lifespan.