Newsroom

QIBR China Manufacturer of Three-Row Cylindrical Roller Combined Slewing Bearing

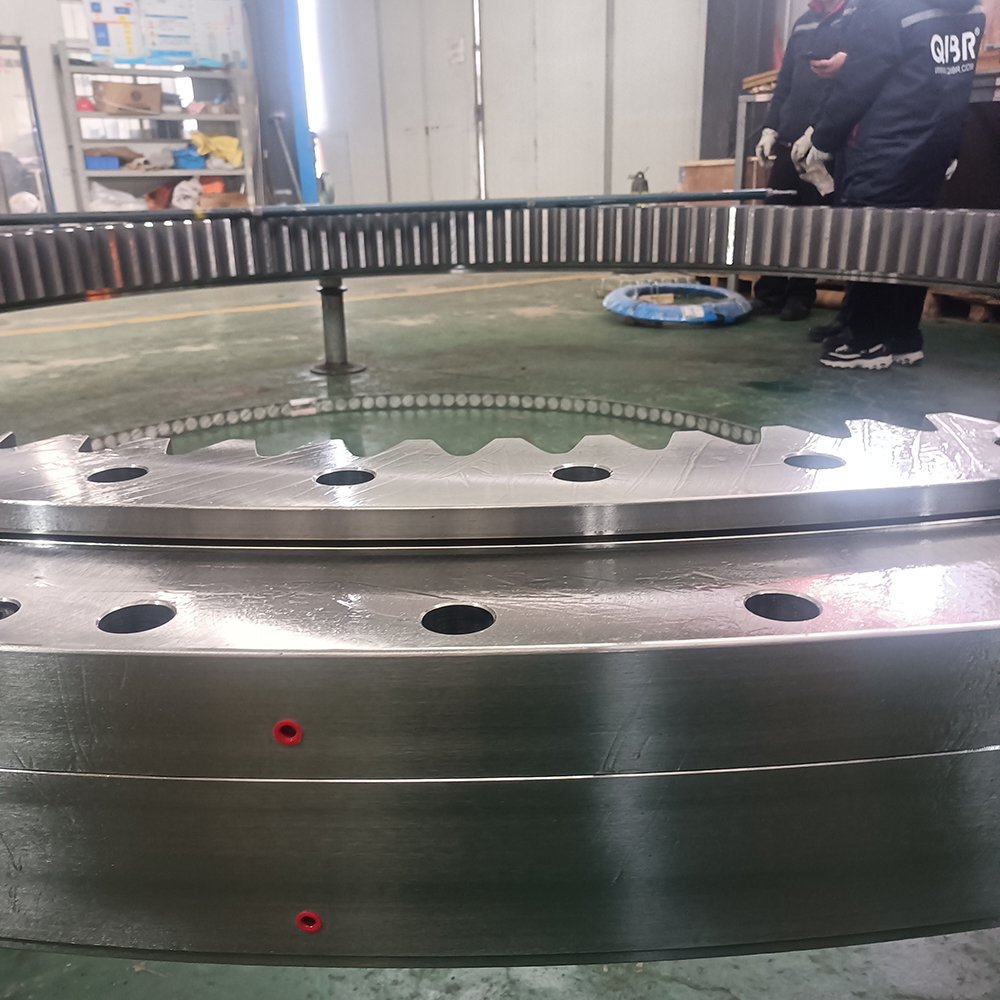

The three-row cylindrical roller combined slewing bearing (TRB) represents a pinnacle of bearing design, engineered to handle extreme multidirectional loads simultaneously. Its architecture comprises three critical ring components: an outer ring and two separate inner rings (first and second inner rings). Between these rings, three distinct raceways are formed:

Axial Load Raceways: Two upper rows dedicated to managing axial loads (parallel to the rotation axis) and tilting moments.

Radial Load Raceway: A third row oriented vertically to withstand radial forces (perpendicular to the axis).

Each raceway houses cylindrical rollers confined by a cage (or retainer), which prevents roller skewing and ensures uniform load distribution. The rollers’ linear contact with raceways provides exceptional load density—enabling TRBs to support weights exceeding thousands of tons while maintaining rotational precision. This multi-row separation is pivotal for handling combined stresses encountered in applications like tunnel boring machines (TBMs) or offshore cranes, where axial, radial, and tipping forces act concurrently.

Material Selection and Precision Manufacturing

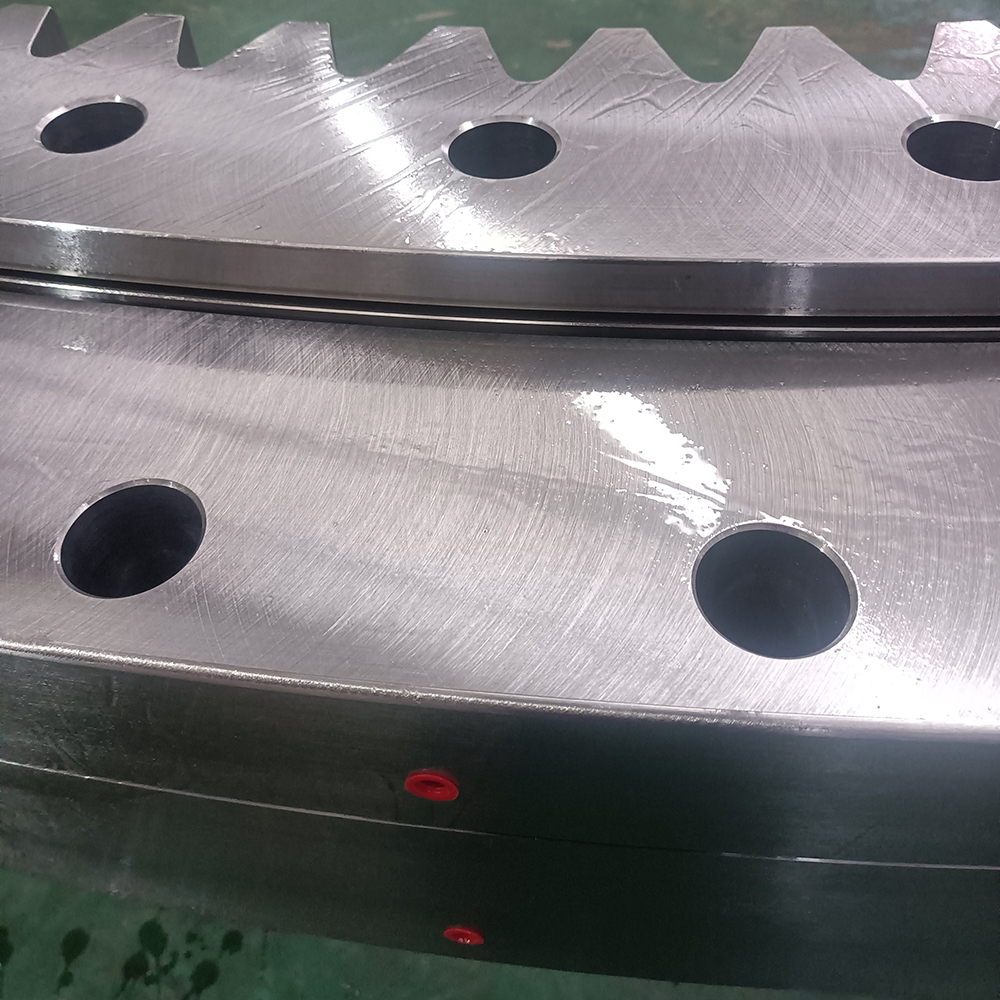

Material durability defines three-row cylindrical roller combined slewing bearing (TRB) longevity. Rings are typically forged from high-carbon chromium steel (e.g., SAE 52100) or alloy steels (e.g., 42CrMo), hardened to 58–62 HRC for fatigue resistance. For cages—traditionally polymer (PA66) or brass—demanding environments like TBMs necessitate advanced solutions:

Steel-Bronze Hybrid Cages: Alloy steel cages embedded with aluminum bronze or leaded brass friction-reducing pads at roller-contact surfaces. This reduces sliding friction by up to 40% and prevents adhesive wear in poorly lubricated conditions.

Monolithic Cage Designs: Machined from single alloy-steel forgings for structural integrity under shock loads.

Precision grinding achieves raceway surface finishes ≤0.2 μm Ra, while roller diameter tolerances are held within ±2 μm. Such exactness minimizes stress concentrations, extending service life beyond 100,000 operating hours even in abrasive environments.

Smart Monitoring Innovations

A breakthrough in three-row cylindrical roller combined slewing bearing (TRB) technology integrates real-time condition monitoring directly into the bearing assembly. As disclosed in patent CN19132959, micro-sensors are embedded within cage pockets:

Ultra-Miniature Cameras: Mounted on magnetic bases via threaded sleeves, capturing high-resolution images of raceways and rollers.

Onboard Processing: Microcontrollers analyze footage for anomalies (e.g., micro-pitting, debris ingress).

Wireless Data Transmission: 4G/LoRa modules relay diagnostics to external systems.

This system overcomes traditional inspection limitations—eliminating disassembly and enabling predictive maintenance. For example, early crack detection in wind turbine TRBs can prevent catastrophic failures, reducing downtime by 30%.

Industrial Applications

TRBs are indispensable across heavy industries due to their unmatched load versatility:

Tunnel Boring Machines: Withstand earth pressures >10 MPa while rotating cutterheads. Custom cages with bronze guides resist mud contamination.

Offshore Cranes: Manage dynamic loads from vessel motion and cargo lifting.

Wind Turbines: Support nacelles weighing 400+ tons under cyclic bending moments.

Mining Stackers: Rotate under 5,000-ton ore piles with minimal friction losses.

Challenges and Future Directions

Despite robustness, TRBs face challenges:

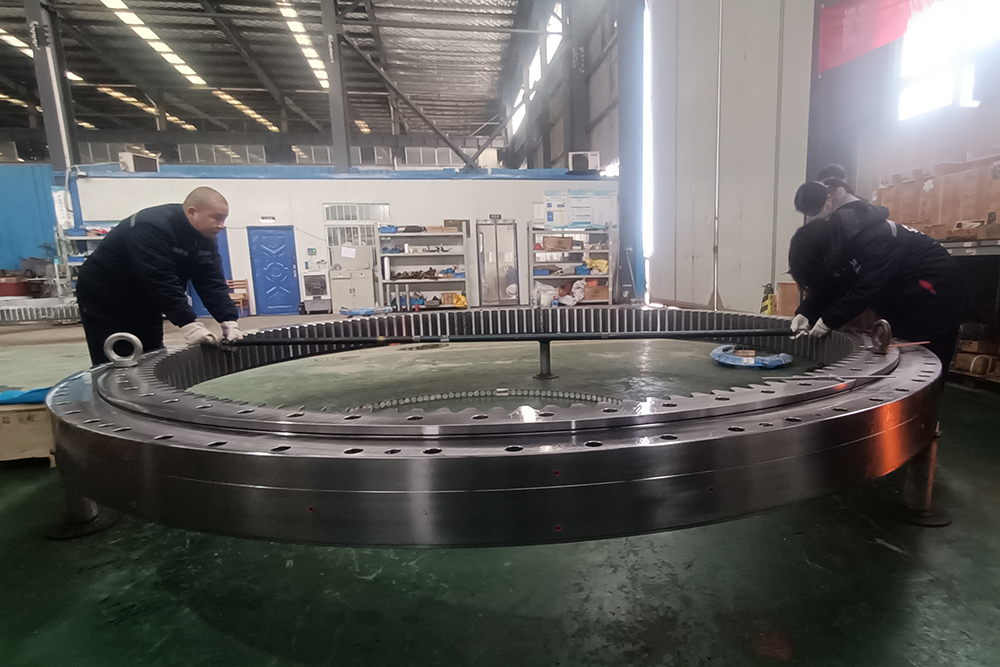

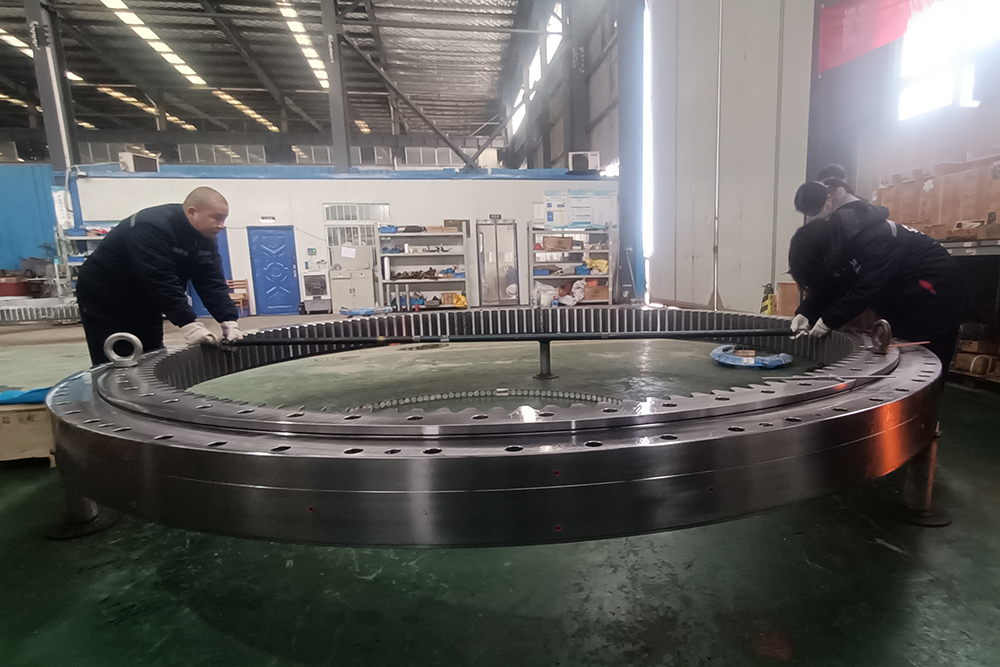

Size Constraints: Diameters up to 15 meters complicate heat treatment uniformity.

Embedded Electronics: Sensor power autonomy and signal integrity under EMI remain active R&D areas.

Lubrication: Grease replenishment in sealed environments (e.g., TBMs) is unsolved.

Emerging trends include carbon-fiber composite cages for weight reduction and AI-based prognostic systems using vibration-acoustic fusion. Hybrid TRBs with magnetic levitation assist are also being prototyped to reduce startup torque by 20%.

Conclusions

The three-row cylindrical roller combined slewing bearing exemplifies mechanical ingenuity—transforming load management in engineering megastructures. Its evolution from passive component to smart system (via embedded sensors and durable material hybrids) highlights a shift toward self-diagnosing machinery. As renewable energy and infrastructure projects scale globally, TRBs will remain critical enablers, merging century-old rolling-contact principles with Industry 4.0 innovation. Future advancements will likely focus on sustainability: extending relubrication intervals, enabling remanufacturing, and reducing friction losses to cut global energy waste.