Newsroom

Structure and Characteristics of Ball Screw

2025-09-29A ball screw is one type of bearing used to convert rotational motion into linear motion or vice versa. Below is a detailed introduction to its structure and characteristics:

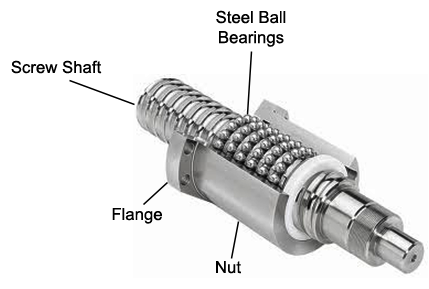

I. Structure

- Screw Shaft: The core component of the ball screw, typically manufactured from high-strength steel. Its surface is precision-machined with a helical raceway, which serves as the guiding path for the rolling balls.

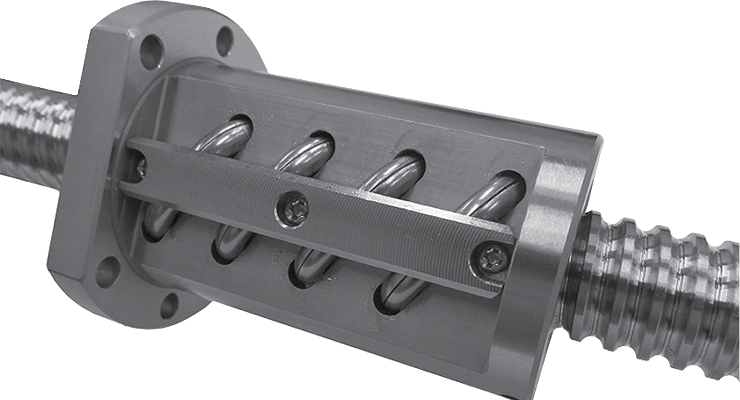

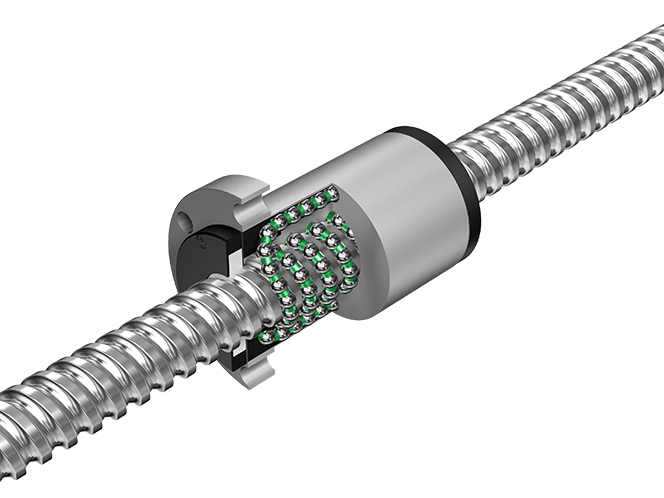

- Nut: Mated with the screw shaft, the nut has a corresponding internal helical raceway that aligns with the one on the screw shaft. When assembled, the nut fits over the screw shaft, and the balls roll between the matching raceways of the two parts.

- Balls: Usually made of high-quality steel (e.g., bearing steel), they have excellent rolling performance and wear resistance. By rolling between the raceways of the screw shaft and nut, the balls facilitate the conversion of motion—turning the screw shaft’s rotation into the nut’s linear movement, or linear movement of the nut into rotation of the screw shaft.

- Cage (Ball Retainer): Commonly crafted from plastic (e.g., POM) or copper alloys. Its key role is to keep the balls spaced evenly within a fixed gap, ensuring they roll freely without mutual collision. It also maintains the balls’ orderly arrangement in the raceway, preventing them from falling out during operation.

- Seals: Typically made of rubber (e.g., nitrile rubber) or metal. They form a barrier to block dust, liquids, and other contaminants from entering the internal raceway system. At the same time, they help retain the internal lubricant (such as grease or oil), ensuring long-term lubrication effectiveness and extending the ball screw’s service life.

II. Characteristics

- High Precision: Advanced manufacturing technologies (e.g., grinding) and strict quality control ensure all components of the ball screw have ultra-high dimensional accuracy and shape precision. This allows it to guide motion with minimal positioning errors (often down to micrometer or even sub-micrometer levels), making it ideal for high-precision equipment like CNC machine tools, semiconductor lithography machines, and precision measuring instruments.

- High Efficiency: Unlike traditional lead screws that rely on sliding friction, the ball screw uses rolling friction between balls and raceways. This significantly reduces frictional resistance, resulting in transmission efficiency as high as 90%–98% (compared to around 30%–50% for sliding lead screws). It thus minimizes energy loss and enables more efficient motion conversion.

- Reversibility: Due to its low frictional resistance, the ball screw can easily convert motion in both directions—rotational motion to linear motion, or linear motion to rotational motion—without additional mechanical adjustments, making it flexible for diverse application scenarios.

- High Rigidity: Through structural optimization (e.g., preloading design) and the use of high-strength materials, ball screws exhibit excellent rigidity. They can resist deformation under axial or radial loads, ensuring stable motion and consistent positioning accuracy even when subjected to external forces or vibration.

- High Load-Carrying Capacity: The circular contact between balls and raceways (via the "Gothic arch" or "circular arc" raceway profile) allows for even distribution of loads. This enables the ball screw to withstand large axial loads (and certain radial loads, depending on the design), making it suitable for heavy-duty equipment such as industrial robots, injection molding machines, and hydraulic presses.

- Low Noise: The cage keeps balls arranged in order, avoiding collisions between balls. Additionally, rolling friction generates far less noise than sliding friction—typically below 60 decibels during operation—making it suitable for noise-sensitive environments like laboratory equipment or medical devices.

- Easy Maintenance: Its relatively simple structure simplifies assembly, disassembly, and inspection. The sealing system effectively protects internal components from contamination, reducing the frequency of cleaning and lubrication. With regular maintenance (e.g., periodic lubricant replacement), ball screws can achieve a long service life (often tens of thousands of operating hours).