Newsroom

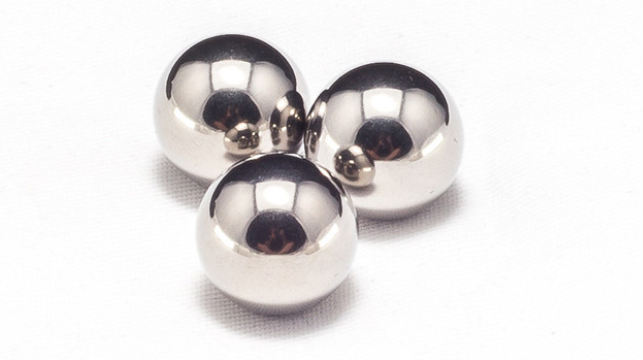

Surface Quality Control in Steel Balls Precision Finishing

2025-07-25Lapping and Superfinishing as Final Processing Stages for Steel Balls

Lapping and superfinishing are both final processing operations for steel balls. For balls requiring a precision level higher than G40, superfinishing is generally necessary. The final dimensional deviation, geometric accuracy, surface roughness, surface quality, and burn-free condition must all meet the technical requirements specified in the process specifications for lapping or superfinishing.

When checking the diameter deviation and geometric accuracy of steel balls, measurement must be performed using designated specialized instruments. The surface roughness and surface quality of workpieces after lapping are generally inspected visually under diffused lighting. In case of disputes, inspection can be carried out using a 90× magnifying glass and compared with standard reference photos. For workpieces after superfinishing, a certain number must be randomly sampled for inspection under a 90× magnifying glass and compared with standard photos. If visual assessment of surface roughness is inconclusive, a surface roughness tester should be used for verification.

Burn inspection after lapping or superfinishing is conducted by random sampling, and the sample quantity and quality standards must comply with the burn inspection criteria.

1.Causes of Poor Overall Surface Roughness:

- Insufficient material removal or too short processing time

- Grinding plate grooves too shallow, resulting in inadequate contact area between the groove and the workpiece

- Grinding plate hardness too high or uneven, with possible sand holes or pores

- Excessive amount of lapping paste, or overly coarse abrasive particles

- Dirty grooves on the grinding plate, containing iron filings or other debris

2.Causes of Localized Poor Surface Roughness:

Although eddy current sorting can identify some soft spots, the wide variation in hardness and area size limits detection accuracy. Optical sorting machines are even less effective, often failing to detect and eliminate such defects.

Surface Scratches (Lapping Damage)

Surface scratches are a common defect in cyclic processing. When severe, they are clearly visible under diffused light as deep pits. In mild cases, they may appear as dark or yellowish spots under diffused lighting, but under 90× magnification, pits with rough bottoms and intersecting scratches can be observed.

Causes include:

- Uneven depth of grinding plate grooves, where workpieces in deeper grooves receive less pressure and intermittently pause or slide, causing surface damage

- Chipping on groove walls of the grinding plate, which can scratch the workpieces during contact

For more information, feel free to contact QIBR