Newsroom

What are Characteristics and Advantages of Ceramic Bearings?

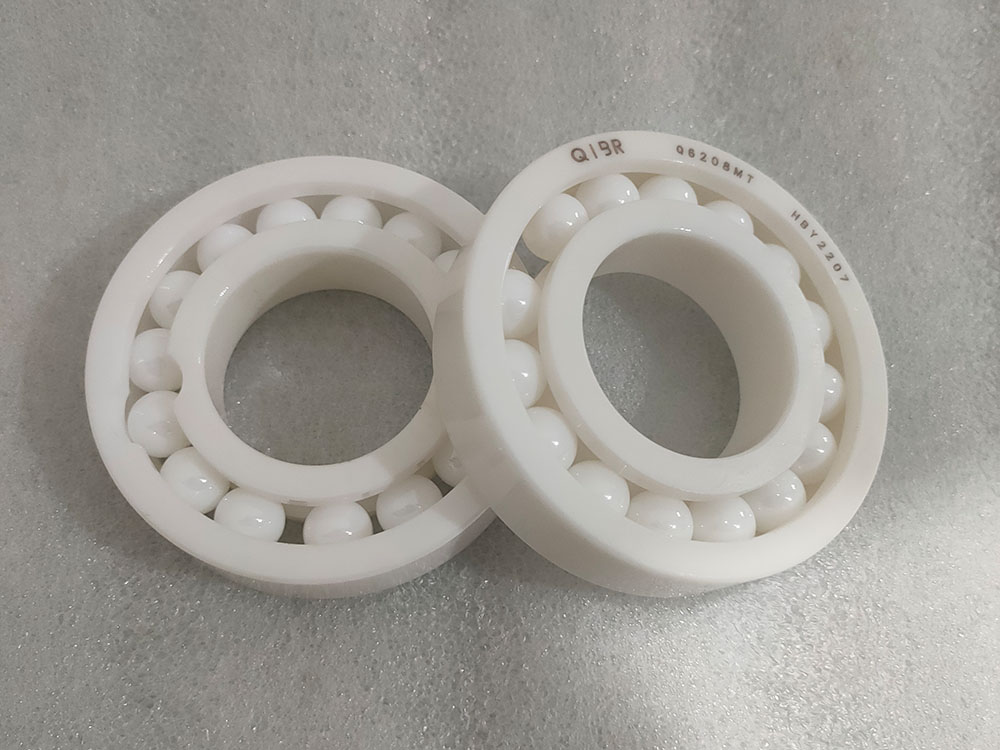

2024-09-25Ceramic bearings have gained significant attention in various industries due to their unique properties and advantages over traditional steel bearings. Made primarily from advanced ceramic materials such as silicon nitride (Si3N4) or zirconia (ZrO2), these bearings are engineered to meet the demanding requirements of high-performance applications. This article explores the key characteristics and benefits of ceramic bearings, highlighting why they are increasingly favored in precision engineering and other fields.

Key Characteristics of Ceramic Bearings

1. High Hardness:

Ceramic materials exhibit exceptional hardness, often three to five times harder than steel. This property allows ceramic bearings to withstand higher loads without deforming, making them suitable for applications that require durability under stress.

2. Low Friction:

Ceramic bearings are designed to operate with reduced rolling resistance, which translates into lower friction during operation. The smooth surface finish of ceramic balls contributes to this efficiency, enhancing overall performance by minimizing energy loss.

3. Corrosion Resistance:

Unlike steel bearings, ceramic bearings are highly resistant to corrosion from moisture, chemicals, and other harsh environments. This makes them ideal for applications in marine settings or industries where exposure to corrosive substances is a concern.

4. Temperature Resistance:

Ceramic materials can withstand extreme temperatures without losing their structural integrity. This characteristic allows ceramic bearings to perform reliably in high-temperature environments where steel bearings might fail due to thermal expansion or degradation.

5. Electrical Insulation:

Ceramic bearings are non-conductive, making them suitable for use in electrical applications where current flow could damage traditional metal bearings. This property is particularly beneficial in motors and generators.

6. Weight Reduction:

Ceramic bearings are generally lighter than their steel counterparts, which can be advantageous in applications where weight savings are critical, such as aerospace and high-performance automotive sectors.

Advantages of Using Ceramic Bearings

1. Extended Lifespan:

Due to their hardness and resistance to wear, ceramic bearings typically have a longer lifespan compared to traditional steel bearings. They can operate effectively in dry or minimal lubrication conditions, often marketed as "maintenance-free" or "self-lubricating" options.

2. Reduced Maintenance:

The durability and corrosion resistance of ceramic bearings lead to lower maintenance requirements over time. This can result in significant cost savings for industries that rely on continuous operation without frequent downtime for repairs or replacements.

3. Performance in Extreme Conditions:

Ceramic bearings excel in environments that challenge conventional materials, such as high-speed applications or those exposed to aggressive chemicals. Their ability to maintain performance under such conditions makes them invaluable in specialized fields like aerospace and medical devices.

4. Lower Rolling Resistance:

The reduced friction associated with ceramic bearings can lead to improved efficiency in mechanical systems. This is particularly beneficial in applications where energy conservation is a priority, such as electric vehicles and precision machinery.

5. Versatility Across Industries:

The unique properties of ceramic bearings enable their use across a wide range of industries, including automotive, aerospace, medical devices, and even sports equipment like bicycles and skateboards. Their adaptability makes them a preferred choice for engineers seeking reliable solutions for demanding applications.

Considerations When Choosing Ceramic Bearings

While the advantages of ceramic bearings are compelling, there are also considerations that potential users should keep in mind:

- Cost: Ceramic bearings tend to be more expensive than traditional steel options due to the complexity of their manufacturing processes and the materials used. Organizations must weigh the benefits against the initial investment when deciding whether to switch from steel to ceramic.

- Brittleness: Although ceramic materials are hard, they can also be more brittle than steel. Under extreme shock loads or impacts, ceramic bearings risk cracking or shattering, which may limit their application in certain high-impact scenarios.

- Load Capacity: Generally, ceramic bearings have a lower load capacity compared to high-quality steel bearings. Users must assess the specific load requirements of their application before selecting ceramic options.

Conclusion

Ceramic bearings represent a significant advancement in bearing technology, offering numerous advantages that make them suitable for high-performance applications across various industries. Their unique characteristics—such as high hardness, low friction, corrosion resistance, and lightweight—position them as superior alternatives to traditional steel bearings in many cases.

As technology continues to evolve and manufacturing processes improve, it is likely that the adoption of ceramic bearings will increase further, making them an attractive option for engineers looking for reliable solutions that enhance performance while reducing maintenance needs. Ultimately, the choice between ceramic and steel bearings should be based on a careful evaluation of application requirements, budget considerations, and performance expectations.