Newsroom

What are QIBR insulated bearings?

In the intricate world of rotating machinery like electric motors, generators, wind turbines, and power transmission systems, an invisible threat silently erodes reliability: stray electrical currents. These currents, often induced by variable frequency drives (VFDs), magnetic dissymmetry, or electrostatic buildup, seek the path of least resistance – frequently finding it through the bearings. The consequences are devastating electrical arcing, pitting, fluting, rapid grease degradation, and catastrophic bearing failure. Enter the specialized solution: Insulated Bearings. These engineered components act as deliberate electrical barriers, preventing damaging currents from flowing through the bearing itself, thereby safeguarding both the bearing and surrounding equipment, significantly extending service life, and enhancing operational reliability.

The Insidious Problem: Electrical Damage Mechanisms

Understanding the critical role of insulated bearings requires grasping the destructive processes they prevent:

1. Electrical Discharge Machining (EDM): When voltage builds up across the oil film separating bearing raceways and rolling elements, it eventually discharges. These microscopic arcs, akin to tiny lightning strikes, vaporize minute amounts of metal, creating characteristic pits or flutes (washboard-like patterns) on the bearing surfaces. This damages the critical smooth finish, accelerates wear, generates excessive noise and vibration, and leads to premature failure.

2. Electrolytic Corrosion: Stray currents can cause electrochemical reactions within the lubricant. This electrolysis process corrodes bearing steel surfaces and chemically breaks down the greased base oil and thickeners. The resulting loss of lubrication properties and corrosive pitting further accelerates wear and seizure.

3. Weld Spatter & Fusion: In severe cases involving high currents (e.g., from welding on connected structures without proper grounding), arcing can generate enough localized heat to actually weld rolling elements to raceways, causing instantaneous catastrophic failure.

The Shielded Solution: Types of Insulated Bearings

To combat these threats, several specialized bearing designs create a high-resistance barrier within the current path. The primary types are:

1. Ceramic Insulated Bearings:

Concept: Utilize non-conductive ceramic materials for key components.

Full Ceramic: Both the rolling elements (balls or rollers) and the inner and outer rings are made entirely from advanced ceramics like Silicon Nitride (Si3N4) or Zirconia (ZrO2). These offer exceptional electrical insulation (>10^14 Ω), excellent corrosion resistance, high-temperature capability (often exceeding 1000°C), and lower density (reducing centrifugal forces). However, they are significantly more expensive and less impact-resistant than steel.

Hybrid Ceramic Bearings: The most common ceramic-insulated type. Features standard high-quality steel inner and outer rings combined with ceramic rolling elements (almost exclusively Silicon Nitride balls). This design provides excellent electrical insulation (current cannot flow through the ceramic balls), retains the high strength and toughness of steel races, offers lower friction and reduced operating temperatures, and handles higher speeds than all-steel bearings. It's a highly effective and popular solution, especially for motors and spindles.

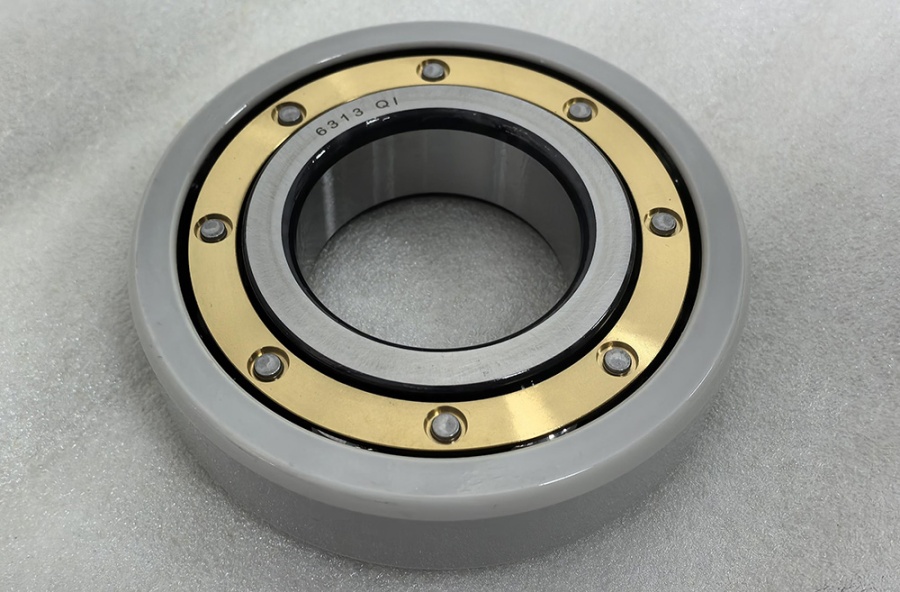

2. Coated Insulated Bearings:

Concept: Apply a robust, dielectric coating onto the surface of the steel outer or inner ring (most commonly the outer ring).

Process: The coating is typically applied using Plasma Spray or High-Velocity Oxygen Fuel (HVOF) techniques onto a specially prepared surface. The most prevalent insulation material is Aluminum Oxide (Alumina, Al2O3), renowned for its excellent dielectric strength, hardness, wear resistance, and adhesion properties. Coatings are usually 100-500 microns thick.

Key Technology - INSOCOAT (SKF): This is a well-established proprietary process where Alumina is plasma-sprayed onto the bearing ring. It provides extremely high insulation resistance (>1000 MΩ at 1000V DC), withstands high temperatures, and integrates seamlessly into standard bearing designs. The coating is highly durable against mechanical and thermal stresses encountered during press-fitting and operation.

Advantages: Cost-effective compared to full ceramic solutions, utilizes standard bearing geometries and load ratings, excellent insulation performance, good mechanical properties. Widely used in electric motors (especially VFD-driven), generators, and traction motors.

3. Electrically Insulated Bearing Units:

Concept: While not a bearing type per se, these pre-assembled units integrate standard bearings with insulation incorporated at the housing interface.

Design: Typically feature an insulated housing (e.g., with a resin layer) or insulated adapter sleeves/inserts between the bearing outer ring and the housing bore. Alternatively, insulation can be placed on the shaft side via special sleeves under the inner ring.

Application: Offers a simplified solution for retrofit or new designs where insulating the entire bearing seat is practical. Provides similar protection but focuses on isolating the entire bearing assembly electrically from the machine structure.

Product Range and Application Diversity

Insulated bearings are manufactured across a wide spectrum of standard bearing configurations to meet diverse application needs:

Electrically Insulated Deep Groove Ball Bearings: The workhorses for radial loads in motors, pumps, and small generators. Commonly coated or hybrid.

Electrically Insulated Angular Contact Ball Bearings: Essential for combined radial/thrust loads in higher-speed applications like machine tool spindles, turbochargers, and compressor shafts. Hybrid designs are prevalent.

Electrically Insulated Cylindrical Roller Bearings: Handle heavy radial loads in generators, large motors, traction drives, and gearboxes. Primarily coated designs due to load requirements.

Electrically Insulated Spherical Roller Bearings: Used in heavy industrial applications like large fans, crushers, and paper mill rolls where misalignment and heavy radial/axial loads exist, often with coated outer rings.

Electrically Insulated Tapered Roller Bearings: Critical for applications with significant combined loads and requiring precise axial location, such as large gearboxes and wheel bearings in electric vehicles/trains.

Ubiquitous Applications: Where Insulation is Paramount

The need for electrical insulation permeates modern industry:

1. Electric Motors (Especially VFD-Driven): The primary application. VFDs induce high-frequency common-mode voltages that cause bearing currents. Virtually all medium/large motors (>100kW) and critical smaller motors on VFDs require insulated bearings (often on the non-drive end).

2. Generators (All Types): Stray currents from magnetic dissymmetry or grounding issues are common threats. Insulated bearings are standard in power generation, from small backup units to massive utility-scale turbines.

3. Wind Turbines: Subject to complex electrical environments (lightning, VFDs for pitch/yaw/doubly-fed generators, static buildup). Insulated generator bearings and often main shaft bearings are critical for reliability and reducing costly turbine downtime.

4. Traction Motors (Rail & EV): High-power inverters and regenerative braking create significant bearing current risks. Insulated bearings are vital for electric locomotives, trams, and increasingly, electric vehicles.

5. Industrial Machinery: Pumps, compressors, fans, conveyors, extruders, machine tools – anywhere VFDs are used or electrostatic buildup occurs (e.g., paper machines, printing presses).

6. Power Transmission Equipment: Large gearboxes in critical drives (mining, cement, marine).

Compelling Advantages: Why Choose Insulation?

The benefits of specifying insulated bearings are substantial and multifaceted:

1. Eliminate Electrical Damage: Directly prevents EDM pitting/fluting, electrolytic corrosion, and fusion, the root causes of premature bearing failure due to stray currents. This is their raison d'être.

2. Dramatically Extended Bearing and Machine Life: By preventing electrical degradation modes, bearings reach their full mechanical fatigue life potential. This translates directly to longer machine uptime and reduced maintenance costs.

3. Enhanced Reliability and Reduced Downtime: Unexpected bearing failures are minimized, leading to more predictable maintenance schedules and significantly higher overall equipment availability. This is crucial for critical processes.

4. Superior Cost-Effectiveness vs. Alternative Methods: While insulated bearings have a premium, they are often more economical than insulating the motor shaft (via complex ceramic-coated sleeves) or the housing (requiring special machining and insulating materials). They offer a direct, integrated, and reliable solution.

5. Maintained Performance: Modern insulated bearings (especially coated and hybrid) retain the full mechanical load rating and performance characteristics of their standard counterparts. Insulation does not compromise bearing function.

6. Reduced Noise and Vibration: Preventing surface damage from arcing helps maintain smooth operation and lower noise/vibration levels.

7. Improved Lubricant Life: By eliminating the electrolytic degradation of grease, lubricant service intervals may potentially be extended, reducing maintenance.

8. Essential for Modern Drives: They are the most reliable and practical solution for the ubiquitous VFD-driven motor, enabling the energy savings and process control benefits of VFDs without sacrificing bearing life.

Selection, Installation, and Care: Ensuring Optimal Performance

Choosing and installing insulated bearings requires attention to detail:

Selection Criteria: Consider voltage levels, frequency, bearing size/type, loads, speeds, temperature, and cost. Coated bearings are often preferred for cost and standard performance; hybrid bearings excel in high-speed/high-temperature scenarios. Consult manufacturer catalogs and engineering support.

Voltage Rating: Ensure the chosen bearing's insulation resistance (tested at standard voltages like 1000V DC) exceeds the expected potential differences in the application.

Careful Handling: Insulated bearings, especially coated types, require careful handling to avoid chipping the coating or contaminating the insulating surface. Avoid impact and keep them clean and dry before installation.

Proper Installation: Follow manufacturer guidelines meticulously.

For coated bearings (outer ring insulated), ensure the housing bore is clean, smooth, and free of burrs. Use correct press-fitting tools to avoid damaging the coating. Never conduct electrical welding on the housing near the bearing or on connected shafts without first establishing a safe grounding path bypassing the bearing.

For hybrid bearings, standard installation practices apply.

Avoiding Grounding Paths: Ensure ancillary components (sensors, seals, housings) do not inadvertently create a conductive path around the insulation. Use insulated mounting hardware if necessary.

Verification: Some manufacturers recommend verifying insulation resistance after installation using a megohmmeter (e.g., 1000V DC), ensuring no short circuits exist.

Conclusion: An Indispensable Defense

Insulated bearings are not merely specialized components; they are fundamental engineering solutions for the electrical challenges pervasive in today's rotating machinery landscape. By effectively blocking the path of destructive stray currents, they protect vital components from insidious electrical damage mechanisms. Whether through the advanced ceramics of hybrid designs or the robust alumina coatings of INSOCOAT technology, these bearings deliver unparalleled reliability and longevity in demanding applications like VFD-driven motors, generators, wind turbines, and traction systems. Their ability to extend equipment life, reduce unplanned downtime, and offer a cost-effective solution compared to alternative insulation methods makes them an indispensable investment for any industry reliant on the smooth, uninterrupted operation of electric drives. As electrical machinery continues to evolve with higher power densities and more complex control schemes, the role of the insulated bearing as a guardian against electrical damage will only grow more critical.