Newsroom

Bearings Types: A Comprehensive Guide

2025-04-15Bearings are critical components in machinery, enabling smooth motion by reducing friction between moving parts. Their design and functionality vary significantly depending on the application, load requirements, and environmental conditions. This article explores the primary types of bearings, their structural differences, and their industrial applications, drawing from international standards and engineering practices.

1. Basic Classification of Bearings Types

Bearings are broadly categorized into rolling bearings and sliding bearings, based on their operating principles and contact mechanisms.

A. Rolling Bearings

Rolling bearings use rolling elements (balls, rollers, or needles) to minimize friction. They are further classified by their load-bearing capabilities and structural designs:

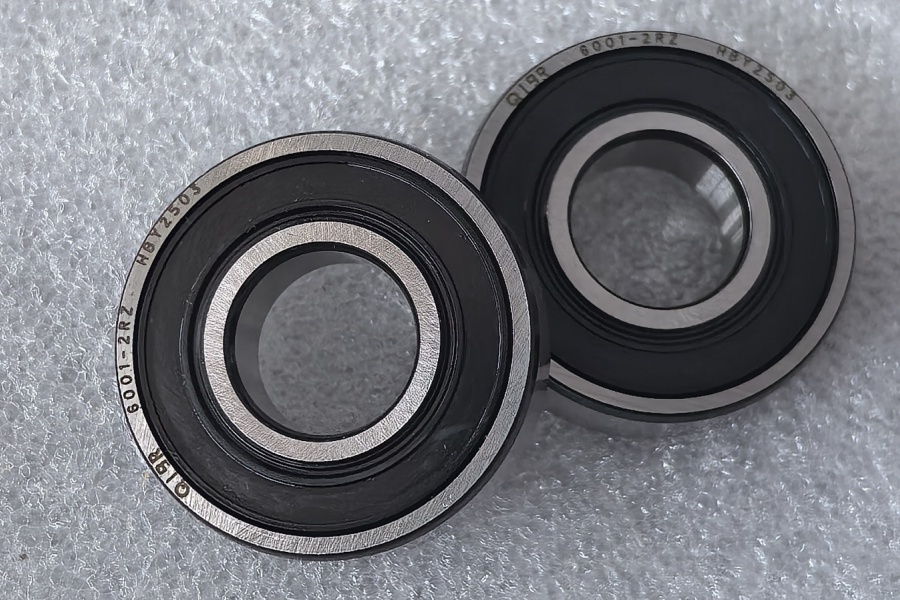

1. Deep Groove Ball Bearings Types

- Structure: A single row of balls running in deep, uninterrupted raceways.

- Load Capacity: Primarily handles radial loads but can withstand moderate axial loads.

- Applications: Electric motors, household appliances, and automotive components.

2. Angular Contact Ball Bearings Types

- Structure: Designed with contact angles (e.g., 15°, 30°, or 40°) between the balls and raceways.

- Load Capacity: Combines radial and axial loads. Higher contact angles improve axial load capacity.

- Applications: Machine tool spindles, pumps, and robotics.

3. Cylindrical Roller Bearings Types

- Structure: Uses cylindrical rollers for line contact with raceways.

- Load Capacity: High radial loads and moderate axial loads.

- Applications: Gearboxes, wind turbines, and heavy machinery.

4. Tapered Roller Bearings Types

- Structure: Conical rollers and raceways arranged to handle combined loads.

- Load Capacity: High radial and axial loads in one direction.

- Applications: Automotive wheel hubs, railroad axles, and construction equipment.

5. Spherical Roller Bearings Types

- Structure: Barrel-shaped rollers and a spherical outer ring raceway for self-alignment.

- Load Capacity: High radial loads and moderate axial loads, with tolerance for misalignment.

- Applications: Mining equipment, paper mills, and vibrating screens.

6. Thrust Bearings Types

- Structure: Includes ball or roller elements arranged perpendicular to the shaft.

- Load Capacity: Designed exclusively for axial loads.

- Subtypes:

- Thrust Ball Bearings: For low-to-moderate axial loads.

- Thrust Roller Bearings: For heavy axial loads (e.g., crane hooks, vertical pumps).

B. Sliding Bearings (Plain Bearings) Types

Sliding bearings operate on sliding contact between surfaces, often using a lubricant film. Key types include:

1. Journal Bearings Types

- Structure: A cylindrical sleeve supporting a rotating shaft.

- Applications: Internal combustion engines, turbines, and compressors.

2. Thrust Sliding Bearings Types

- Structure: Flat or grooved surfaces to support axial loads.

- Applications: Marine propeller shafts and hydraulic pumps.

3. Split Bearings Types

- Structure: Two-piece design for easy installation and maintenance.

- Applications: Large industrial machinery and crankshafts.

4. Self-Lubricating Bearings Types

- Structure: Embedded lubricants (e.g., graphite or PTFE) within the bearing material.

- Applications: Food processing equipment and aerospace systems where lubrication is impractical.

2. Specialized Bearing Types

1. Needle Roller Bearings Types

- Structure: Thin, long rollers for compact designs.

- Advantages: High radial load capacity in minimal axial space.

- Applications: Automotive transmissions and planetary gear systems.

2. Magnetic Bearings Types

- Structure: Uses electromagnetic forces to levitate the shaft without physical contact.

- Advantages: Zero friction, high-speed capability, and no lubrication required.

- Applications: Turbomachinery, high-speed trains, and flywheel energy storage.

3. Fluid Film Bearings Types

- Structure: Relies on pressurized fluid (oil, water, or gas) to separate surfaces.

- Types: Hydrodynamic (self-generated pressure) and hydrostatic (externally pressurized).

- Applications: Power generation turbines and precision machine tools.

4. Pillow Block Bearings Types

- Structure: Rolling bearings housed in a mounted unit with a base for easy attachment.

- Applications: Conveyor systems, agricultural machinery, and HVAC fans.

3. Material Considerations

Bearing performance heavily depends on material selection:

- Chromium Steel (GCr15): Standard for most rolling bearings due to high hardness and wear resistance.

- Stainless Steel (440C/304): Offers corrosion resistance for marine or medical applications.

- Ceramic Hybrids: Silicon nitride (Si3N4) balls paired with steel rings reduce friction and heat in high-speed applications.

- Polymers (PTFE, Nylon): Used in sliding bearings for self-lubrication and chemical resistance.

4. Applications Across Industries

- Automotive: Tapered roller bearings in wheel hubs, ball bearings in alternators.

- Aerospace: High-precision angular contact bearings in jet engines.

- Industrial Machinery: Spherical roller bearings in crushers and vibrating screens.

- Renewable Energy: Cylindrical roller bearings in wind turbine gearboxes.

- Consumer Electronics: Miniature ball bearings in hard drives and drones.

5. Selection and Maintenance Tips

1. Load and Speed: Match bearing type to load direction (radial/axial) and rotational speed.

2. Environment: Choose stainless steel or sealed bearings for corrosive or dusty conditions.

3. Lubrication: Regular greasing extends life in rolling bearings; self-lubricating options suit inaccessible locations.

4. Alignment: Ensure proper shaft alignment to prevent premature wear, especially in sliding bearings.

Conclusion

From the simplicity of deep groove ball bearings to the complexity of magnetic levitation systems, bearings are engineered to meet diverse mechanical demands. Understanding their types, materials, and applications allows engineers to optimize performance, reduce downtime, and extend machinery lifespan. As industries evolve, innovations in bearing technology—such as hybrid ceramics and smart sensors—continue to push the boundaries of efficiency and durability.